- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HUAYE

-

Power:

-

1500-2000KW

-

Weight:

-

60000 kg

-

Round pipe:

-

219 -406mm

-

Square profiles:

-

130*130-300*300 mm

-

Wall thickness:

-

3.0-12.7 mm

-

Coil I.D.:

-

508/760mm

-

Coil O.D.:

-

1500-2300mm

-

Maximum weight:

-

40tons

-

Welding:

-

Solid state HF 600KW

-

Forming Type:

-

Cold roll forming, form round weld square

-

Forming& welding speed:

-

8-20m/min

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

hundreds tons/ month

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

HUAYE

-

Power:

-

1500-2000KW

-

Weight:

-

60000 kg

-

Round pipe:

-

219 -406mm

-

Square profiles:

-

130*130-300*300 mm

-

Wall thickness:

-

3.0-12.7 mm

-

Coil I.D.:

-

508/760mm

-

Coil O.D.:

-

1500-2300mm

-

Maximum weight:

-

40tons

-

Welding:

-

Solid state HF 600KW

-

Forming Type:

-

Cold roll forming, form round weld square

-

Forming& welding speed:

-

8-20m/min

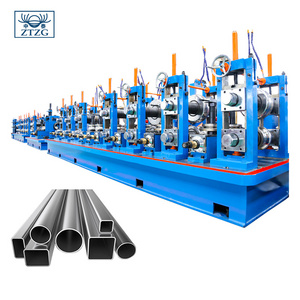

Steel Tube Production Line Round Square Pipe Making Machine ERW Pipe Mill Machine

Technical Specification

|

HG-114 |

Φ25~Φ114 |

3~8 |

5 |

30~60 |

~1100 |

12×100 |

|

HG-168 |

Φ60~Φ168 |

3~10 |

10 |

20~40 |

~1600 |

12×100 |

|

HG-219 |

Φ114~Φ219 |

4~12 |

15 |

10~30 |

~1800 |

15×150 |

|

HG-325 |

Φ165~Φ325 |

4~14 |

20 |

8~25 |

~3000 |

18×180 |

|

HG-355 |

Φ165~Φ355 |

4~14 |

20 |

8~25 |

~3500 |

18×180 |

|

HG-406 |

Φ219~Φ406 |

4~16 |

30 |

8~20 |

~4000 |

21×180 |

|

HG-508 |

Φ219~Φ508 |

4~16 |

30 |

8~20 |

~4500 |

21×260 |

|

HG-610 |

Φ219~Φ610 |

4~20 |

30 |

8~20 |

~5000 |

24×280 |

More Pictures Show

1.Brief introduction of ERW tube mill & pipe mill

- The ERW tube mill & pipe mill is a series of machines that builds longitudinal weld seam tubes and pipes with steel strips of certain width.

- It starts by uncoil and flatten the slitted steel coils into steel strips.

- The flattened steel strips will then be inserted into the forming machine and the roller tolling in the machine will roll the strip to round pipe shape.

- The rolled strips will then be sent into the weld box where the tube is welded by a high frequency solid state welder.

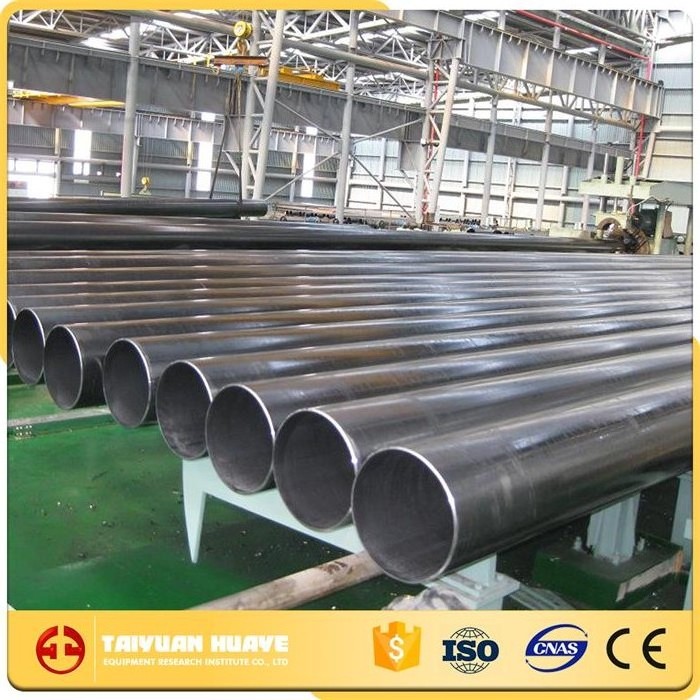

- The welded tubes will be formed to expected shape or size in a sizing machine. Finally the tubes will be cut to length and bundled.

-

ERW pipe mills is a characterized product of HUAYE that are developed through years of research to combine the advanced knowledge and technology of the market.

The main product includes high-level steel casing and tubing pipe mill, structure pipe mill, fluid transfer pipe mill, and small dia. thick wall pipe mill.

HUAYE has an experienced team with strong technical skill and knowledge. Through years of hard work, HUAYE’s ERW pipe mill has occupied the market of more than 20 provinces of China and was exported to Korea, Mexico, Thailand, Uzbekistan, Kazakhstan etc. HUAYE ERW pipe mill were highly received by customers from China and over the world.

2. Function

This pipe is used especially for Petroleum, Natural gas, City gas, Pipe network, Chemical industry, Electricity, Steel truss, Water and Gas pipeline; it is widely used for a variety of pressure

3.Process flow

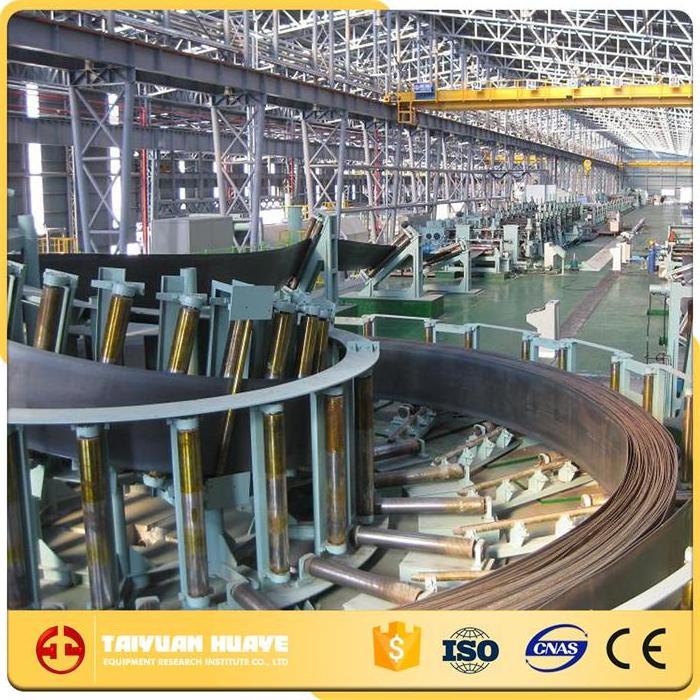

Feed - uncoil - straighten - shear and buttweld - loop storage - form - HF welder - IF anneal - cool - size -cut - output - end bevel - hydraulic test - collect .

4. Machine parts in the working line

(1) Uncoiler

(2) Hoop cage or Horizontal Accumulator

(3) Main Machine:

- Forming Machine

- Roller System of Forming

- Seam Guide

- High Frequency Induction Welding Machine

- Roller System for Moving

- Burr Removing Frame (Inside and outside Burr )

- Water Cooling System

- Sizing Machine

- Roller System of Leveling

- Speed Testing Wheel

- Turkish Frame

- Auto Flying Saw Controlled by Computer

- Run out table

- Electric Control Equipmen

- High Frequency Welding Machine