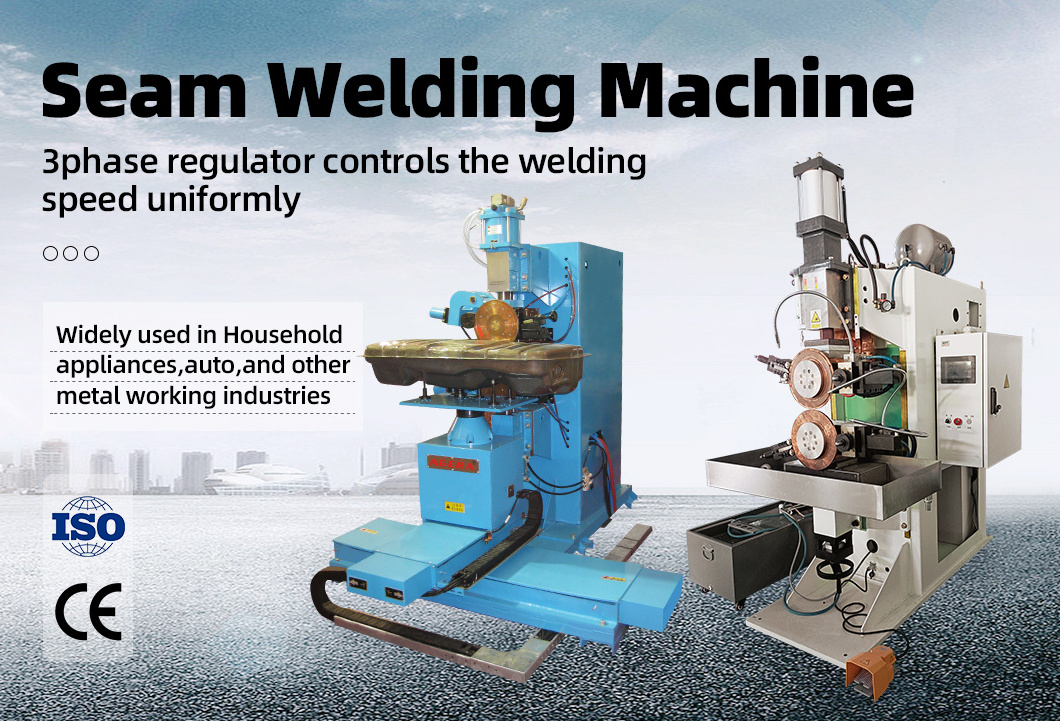

Agera pays attention to product research & development, service, constantly absorbs and supply trains to improve the company's

technical and management capabilities. Supply complete sets of equipment and process solutions, and can provide clients with the customization of automatic welding equipment. We strive to create value for customers and contribute to the development of industrial automation! Welcome to visit and inspect the factory.

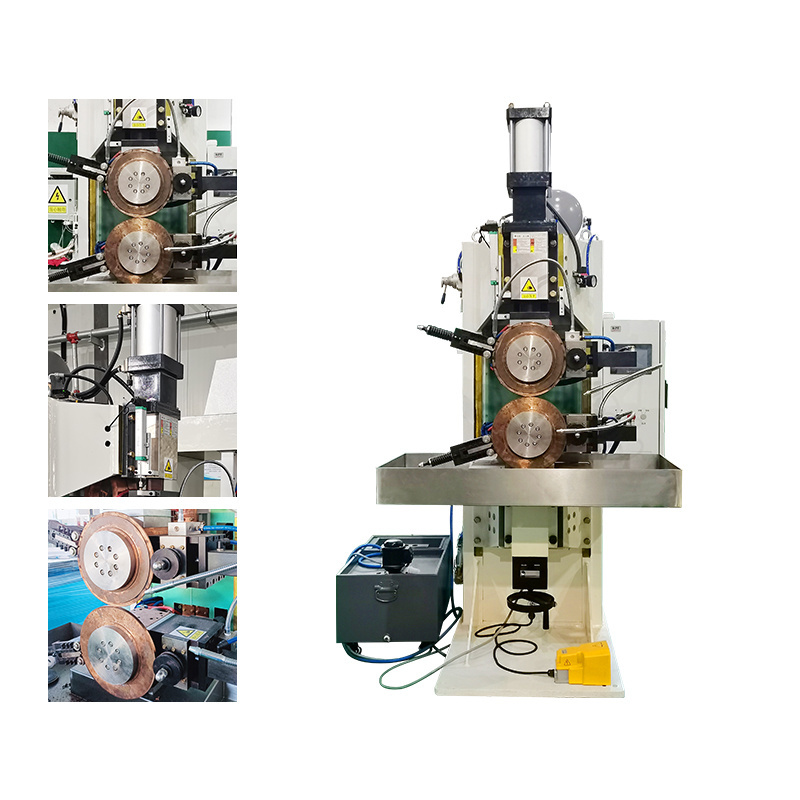

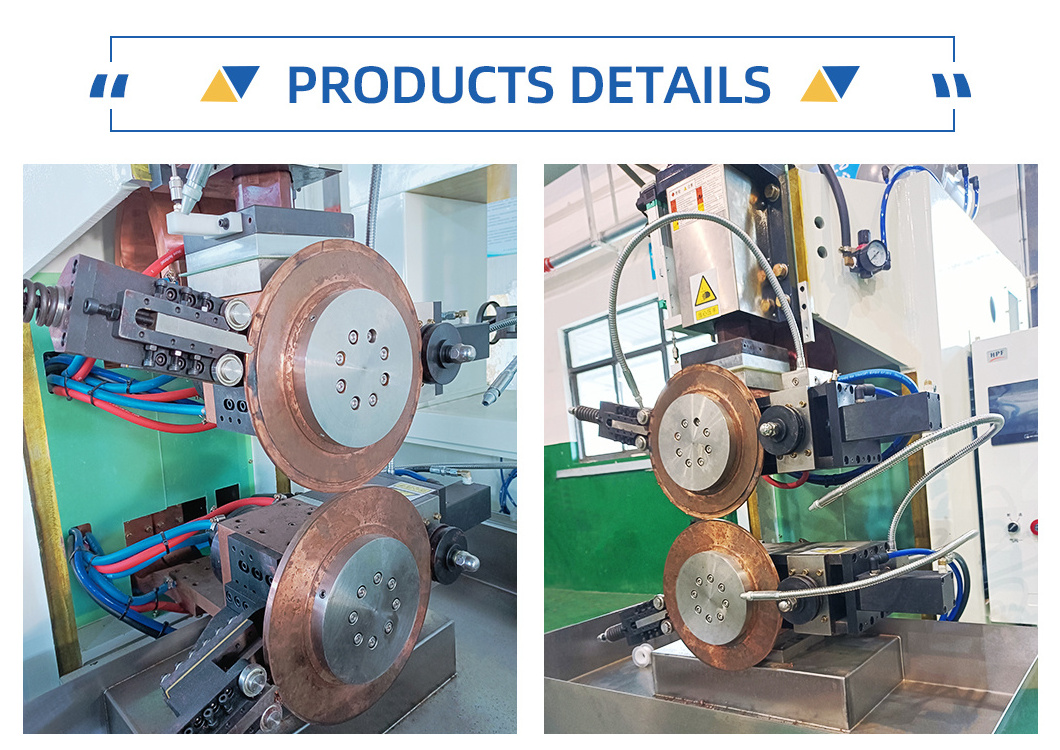

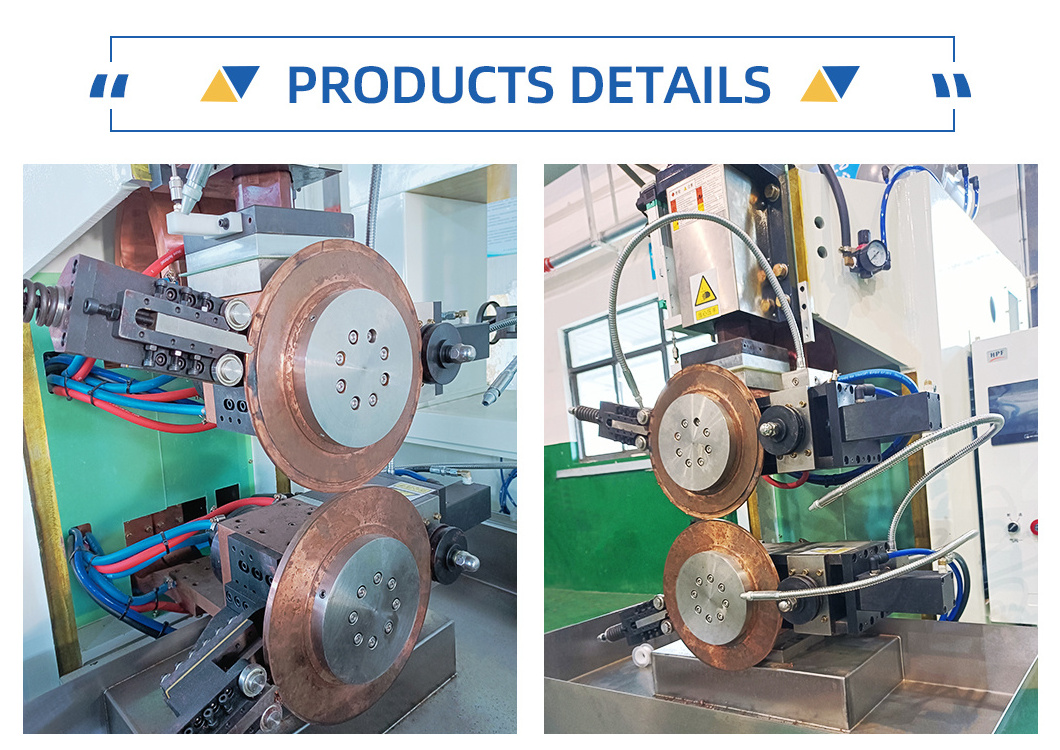

- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

50mm-150mm

-

Welding Diameter:

-

100-500mm

-

Dimensions:

-

1415*1475*2000

-

Use:

-

welding

-

Voltage:

-

220V, 380V

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

-

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

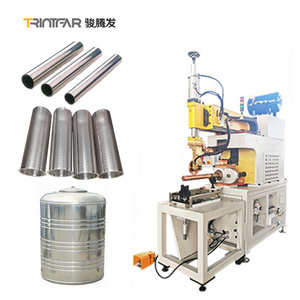

Seam Welding Machine

-

Application:

-

Metal Sheet

-

Certification:

-

ISO CE

-

Welding Method:

-

Automation

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Agera

-

Forming Time:

-

5s-10s adjustable

-

Welding Mode:

-

50mm-150mm

-

Welding Diameter:

-

100-500mm

-

Dimensions:

-

1415*1475*2000

-

Use:

-

welding

-

Voltage:

-

220V, 380V

-

Weight (KG):

-

2000 KG

-

Power (kW):

-

-

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Seam Welding Machine

-

Application:

-

Metal Sheet

-

Certification:

-

ISO CE

-

Welding Method:

-

Automation

Q:Do your factory sale directly?

A: Yes, it is. Our factory sale directly, competitive price with high quality.

Q: Can you export machines by your factory.

A:Yes, we can

Q:Where are your factory?

A: Xiangcheng District, Suzhou City, Jiangsu Province, China

Q:What do we need to do if the machine fails.

A:In the guarantee time(1 year), we will send the spare parts to you for free. And provide the technical consultant for any time.

Q:Can I make my own design and logo on the product?

A: Yes, we do OEM.Welcome global partners.

Features of The Intermediate Frequency Spot Welder

1. Three-phase power supply, grid balance, small impact on the grid

The power factor is as high as 0.7-0.9 (power frequency 0.4), which greatly reduces the reactive power loss;

2. Significantly improved welding control accuracy

The inverter frequency reaches above 1000Hz, and the welding current control ability and control accuracy are 20 times higher than those of AC welding machines;

3. Great leap in welding quality

The current waveform is straight, the size of the nugget is stable, the spatter is less, and the surface quality of the solder

joint is good;

4. Save basic investment and save energy

The grid power demand is low, only 2/3 of the AC resistance welding machine; the welding time is short and the electrode life is long;

5. Human-computer interface, easy to operate

Multiple sets of welding specifications can be stored and called with one key, real-time display of welding current and time; monitoring and alarm functions of welding pressure, cold water flow, and welding current.

|

Model

|

Power Supply

ø/V/HZ

|

Primary Cable

mm²

|

Max Primary Current

(

KA)

|

Rated Duty Cycle

(%)

|

Welding Cylinder Size(Ø*L)

|

Max Working Pressure(0.5MP) N

|

Compressed Air Consumption (Mpa)

|

Cooling Water Consumption (L/Min)

|

Compressed Air Consumption (L/次)

|

|

ADB-5

|

1/220V/50Hz

|

2×10

|

2

|

5

|

Ø25*30

|

240

|

0.6-0.7

|

-

|

1.23

|

|

ADB-10

|

|

2×10

|

4

|

5

|

Ø32*30

|

400

|

|

-

|

1.43

|

|

ADB-75T

|

3/380V/50Hz

|

3×16

|

18

|

20

|

Ø50*40

|

980

|

|

6

|

1.43

|

|

ADB-100T

|

|

3×16

|

28

|

20

|

Ø80*50

|

2500

|

|

6

|

2.0

|

|

ADB-100

|

|

3×16

|

28

|

20

|

Ø100*60

|

3900

|

|

8

|

2.28

|

|

ADB-130

|

|

3×16

|

37

|

20

|

Ø125*100

|

6000

|

|

12

|

5.84

|

|

ADB-130Z

|

|

3×16

|

37

|

20

|

Ø160*100

|

10000

|

|

12

|

5.84

|

|

ADB-180

|

|

3×25

|

48

|

20

|

Ø160*100

|

10000

|

|

12

|

5.84

|

|

ADB-260

|

|

3×25

|

60

|

20

|

Ø160*100

|

10000

|

|

12

|

5.84

|

|

ADB-360

|

|

3×35

|

70

|

20

|

Ø200*100

|

15000

|

|

15

|

9.24

|

|

ADB-460

|

|

3×50

|

80

|

20

|

Ø250*150

|

24000

|

|

20

|

9.24

|

|

ADB-690

|

|

3×75

|

100

|

20

|

Ø250*150*2

|

47000

|

|

24

|

26

|

|

ADB-920

|

|

3×90

|

120

|

20

|

Ø250*150*2

|

47000

|

|

30

|

26

|

Suzhou Agera Automation Equipment Co., Ltd.

is a professional research and development enterprise of resistance welding and automation equipment, “Professional, refinement, specialization and novelty” company, private technology enterprise in Jiangsu Province. The company has passed ISO9001 quality management system certification and CE certification. With an excellent R&D, production and sales service team, more than 20 years of welding technology precipitation, more than 50 inventions and utility model patents, 3000+ customer experience in service, 30000+ welding workpiece cases.

The company's main products are intermediate frequency inverter spot welding machine, heavy duty intermediate frequency ring convex welding machine, capacitor discharge spot welding machine, integrated suspension spot welding machine, flash butt welding machine, resistance butt welding machine, automatic butt welding slag scraper Machines, and various customized automatic spot welding machines, automatic projection welding machines, robot projection welding, spot welding workstations, fully automatic welding production lines, automatic testing equipment, etc. It is widely used in automobile manufacturing, electronic and electrical appliances, household appliances,

hardware tools, machinery manufacturing and other industries, and has provided equipment and services for many well-known enterprises at home and abroad.

hardware tools, machinery manufacturing and other industries, and has provided equipment and services for many well-known enterprises at home and abroad.

Q:Do your factory sale directly?

A: Yes, it is. Our factory sale directly, competitive price with high quality.

Q: Can you export machines by your factory.

A:Yes, we can

Q:Where are your factory?

A: Xiangcheng District, Suzhou City, Jiangsu Province, China

Q:What do we need to do if the machine fails.

A:In the guarantee time(1 year), we will send the spare parts to you for free. And provide the technical consultant for any time.

Q:Can I make my own design and logo on the product?

A: Yes, we do OEM.Welcome global partners.

Hot Searches