- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

220V/380V/480V

-

Dimension(L*W*H):

-

110*14*6meter

-

Weight:

-

30000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

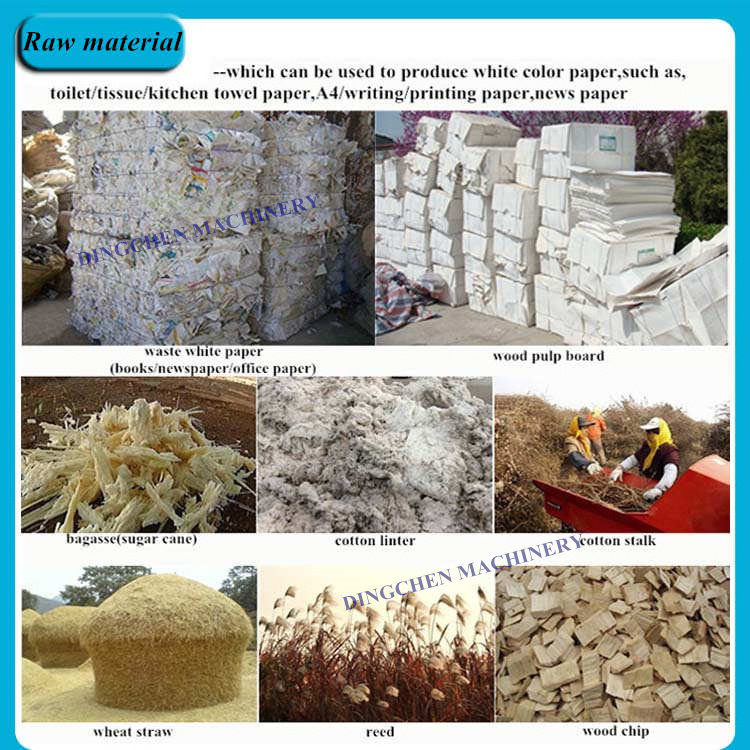

Raw material:

-

waste office paper ,wood pulp board

-

Output paper:

-

printing paper ,office paper ,a4 paper

-

Output paper weight:

-

60-80g/

-

Net paper width:

-

2400mm

-

Wire width:

-

2950mm

-

Rail gauge:

-

3400mm

-

Capacity:

-

30tons/day

Quick Details

-

Type:

-

paper making machine, paper production line

-

Production Capacity:

-

350 m/min

-

Max. workable width:

-

1300mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

220V/380V/480V

-

Dimension(L*W*H):

-

110*14*6meter

-

Weight:

-

30000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

waste office paper ,wood pulp board

-

Output paper:

-

printing paper ,office paper ,a4 paper

-

Output paper weight:

-

60-80g/

-

Net paper width:

-

2400mm

-

Wire width:

-

2950mm

-

Rail gauge:

-

3400mm

-

Capacity:

-

30tons/day

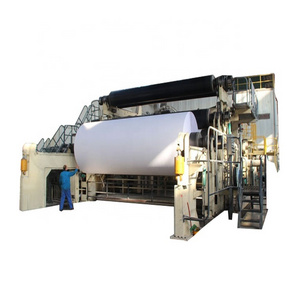

Energy Saving paper and pulp mill a4 office equipment

Product details

| Raw material | waste office paper ,wood pulp board |

| Output paper | printing paper ,office paper ,a4 paper |

| Output paper weight | 60-80g/ |

| Net paper width | 2400mm |

| Wire width | 2950mm |

| Rail gauge | 3400mm |

| Capacity | 30tons/day |

| Type | paper production line |

| Layout | left or right hand machine |

| Product Keywords | roll writing paper,recycled paper machine,paper producing machine |

Technical parameter

|

1. Raw material |

virgin pulp board |

|

2. Output paper |

office paper, writing and printing paper |

|

3. Output paper weight |

70-80 g/m 2 |

|

4. Net paper width |

2400 mm |

|

5.Wire width |

2800 mm |

|

6. Capacity |

20-30 ton / day |

|

7 .Working speed |

120-140 m / min |

|

8.Design speed |

200m/min |

|

9. Rail gauge |

3100 mm |

|

10. Drive way |

A /C converter speed control, section drive. |

Structure and specifications of main equipments

1. Fourdrinier part:

1 set of 10.83 meters long wire, the wire table coated by stainless steel board,

1 set of Φ 700vacuum couch roll. The head box is made of stainless steel.

2 . P ress part:

1 pc of Φ 6 0 0 mm × 2800 mm× 3100 mm natural marble roll,

1 pc of Φ 55 0 mm × 2800 mm× 3100 mm rubber roll, rubber shore hardness 9 5 ℃±2 , pneumatic pressure device.

3. Dryer part:

1 pc of alloy dryer cylinder, and 14 pcs of Φ1 5 00× 2800 mm× 3100 mm alloy dryer cylinders, arrayed in the order of 1 + 8 + 6, with dry wire device and semi-closed dryer hood s . 1 pc of Φ 45 0 mm × 2800 mm× 3100 mm reverse paper press roll,

1 pc of Φ 55 0 mm × 2800 mm× 3100 mm touch roll, rubber shore hardness 9 0 ℃±2 , with pneumatic pressure device.

4.Calendaring part and winding part:

3 rolls calendaring machine, and drum reeler.

5.Driving & controlling part:

A /C converter speed control, section drive , with 500 speed reducer, digital close-loop controlling system.

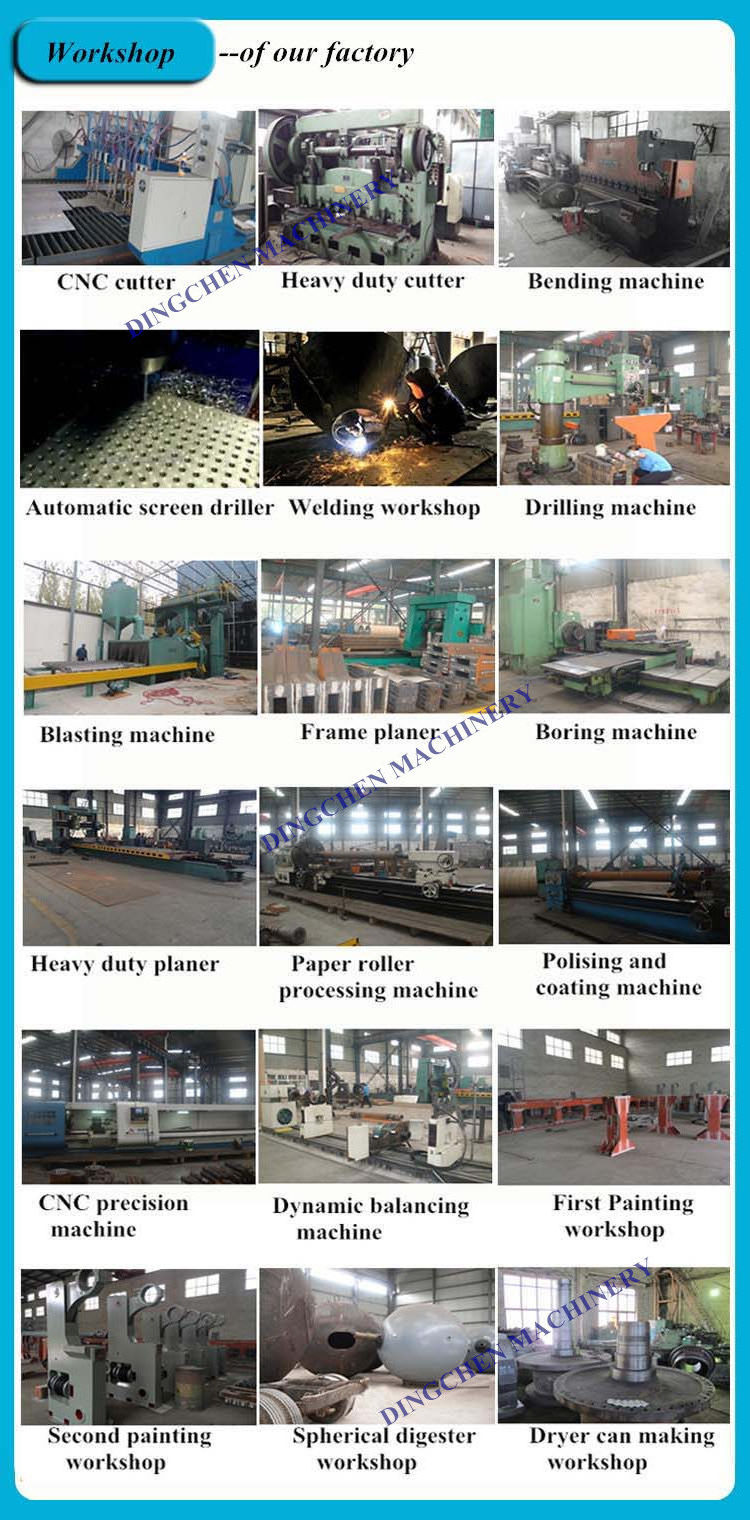

Competitive price and quality.

Extensive experience in production line design and paper machine manufacturing

Advanced technology and state of art design

Stringent testing and quality inspection process

Abundant experience in overseas projects

Excellent After-sales Service

PACKAGE:

Standard export carton packing.