- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DELTA

-

Voltage:

-

380 V 220 V

-

Dimension(L*W*H):

-

20*3*1.5(METER)

-

Power (kW):

-

30

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

hose shape:

-

spiral , flexible , spring, soft

-

raw material:

-

PVC EVA PP PE PA

-

design:

-

latest technology and experiences

-

Automatic Grade:

-

PLC PID

-

Power:

-

30KW

-

Machine type:

-

Single Screw Extrusion Line

-

Usage:

-

vacuum cleaner hose machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DELTA

-

Voltage:

-

380 V 220 V

-

Dimension(L*W*H):

-

20*3*1.5(METER)

-

Power (kW):

-

30

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

hose shape:

-

spiral , flexible , spring, soft

-

raw material:

-

PVC EVA PP PE PA

-

design:

-

latest technology and experiences

-

Automatic Grade:

-

PLC PID

-

Power:

-

30KW

-

Machine type:

-

Single Screw Extrusion Line

-

Usage:

-

vacuum cleaner hose machine

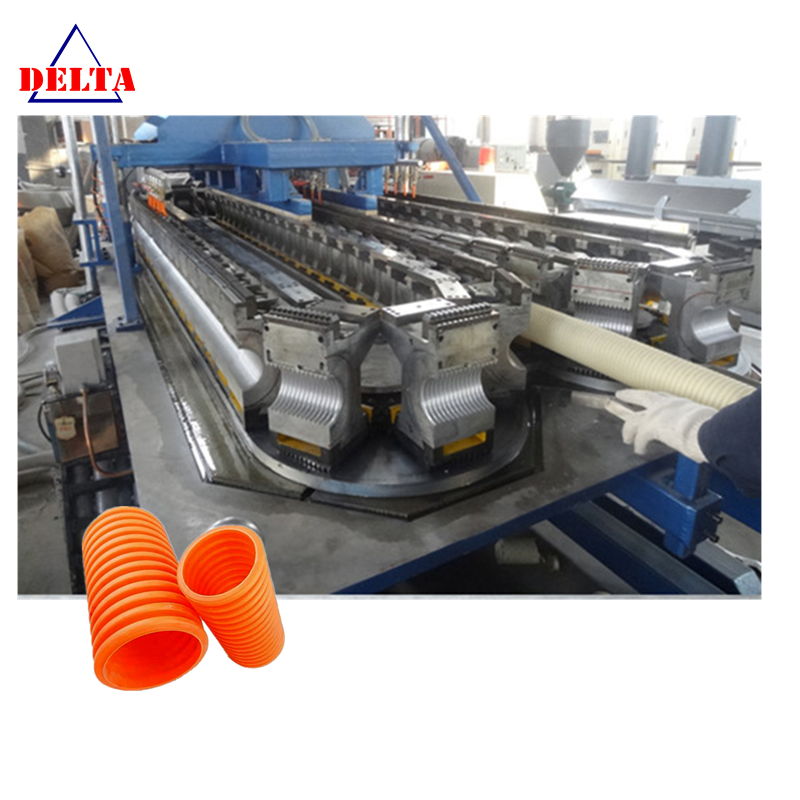

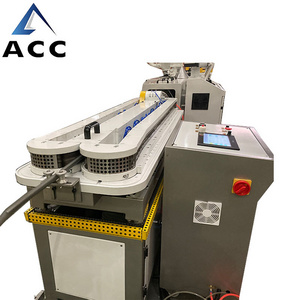

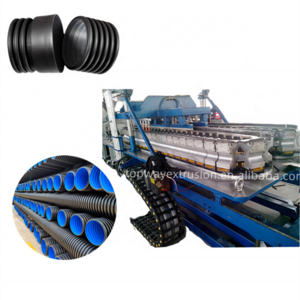

What's the machine can produce

This machine produce PE PP PVC double wall corrugated pipe. it is mainly used in municipal reconstruction engineering, construction, industrial and agricultural drainage, agricultrure water-saving irrigation, sewage treatment engineering and other fields..

PE PP PVC double wall corrugated pipe making machine adopts the direct extrusion (co-extrusion) forming technologh and Siemens man-machine interface control system. It has the advantages of high degree of automation, high output,

reliable quality, stable operation and deep welcomed by domestic and foreign customers.

PE PP PVC double wall corrugated pipe making machine adopts the direct extrusion (co-extrusion) forming technologh and Siemens man-machine interface control system. It has the advantages of high degree of automation, high output,

reliable quality, stable operation and deep welcomed by domestic and foreign customers.

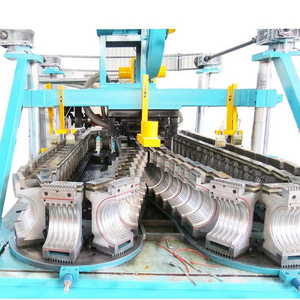

Our Machine Advantages

1. Special designed die head assures produce out high quality high precision good shape pipe.

2. Corrugator adopts holistic and horizontal structure, small floor area and non-base on ground.

3. Work table can be regulated conveniently on lateral, vertical and horizontal direction.

4.ABB governor ensures reliable working ability, stable and full scope of speed adjustment.

5. Forming moulds (air cooling and water cooling) is made of special high quality aluminum alloy, with advantages of light weight,high density, good wearing resistance, small parameter of thermal expansibility,etc.

6. Long forming track and less mould blocks produced by CNC processsing center were to ensure a high precision and good quality.

2. Corrugator adopts holistic and horizontal structure, small floor area and non-base on ground.

3. Work table can be regulated conveniently on lateral, vertical and horizontal direction.

4.ABB governor ensures reliable working ability, stable and full scope of speed adjustment.

5. Forming moulds (air cooling and water cooling) is made of special high quality aluminum alloy, with advantages of light weight,high density, good wearing resistance, small parameter of thermal expansibility,etc.

6. Long forming track and less mould blocks produced by CNC processsing center were to ensure a high precision and good quality.

7. Economic design for your choice .

Finished Products

Machine Details Pictures

|

Main machine model

|

SJ-30

|

SJ-45

|

SJ-65

|

||

|

Pipe diameter range (mm)

|

4.5-9

|

9-32

|

16-50

|

||

|

Main machine L/D

|

30:1

|

28:1

|

30:1

|

||

|

Production capacity (kg/h)

|

10

|

40

|

80

|

||

|

Main motor power (kw)

|

4

|

11

|

18.5

|

||

|

Molding machine power (kw)

|

1.1

|

1.5

|

2.2

|

||

|

Pairs of modules

|

42

|

50

|

50

|

||

|

Production speed (m/min)

|

6-10

|

8-12

|

8-12

|

||

|

Cooling mode

|

Wind and water cooling

|

|

|

||

|

Metering mode

|

Inducting mode

|

|

|

||

|

Coiling machine mode

|

Motor-driven, manually-operated

|

|

|

||

PRODUCT ADVANTAGES

* extruder: adopting conical twin-screw extruder, unique designed screw, realizing shorting plasticizing time, good compounding and excellent plasticization.

* gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

* extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

* screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

* driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

* vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

* haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

* cutting unit: saw cutting and planet saw cutting, with dust collection system.

* stacking unit: automatic overturning system, can freely fix the length of the pipe.

* controlling system: manual controlling cabinet or SIEMENS PLC touch screen controlling

* gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

* extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

* screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

* driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

* vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

* haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

* cutting unit: saw cutting and planet saw cutting, with dust collection system.

* stacking unit: automatic overturning system, can freely fix the length of the pipe.

* controlling system: manual controlling cabinet or SIEMENS PLC touch screen controlling

MACHINERY SHIPPING

FACTORY SHOWING

Hot Searches