- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JianLong

-

Year:

-

2022

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Customized as required

-

Weight (T):

-

7.4 T

-

Model Number:

-

JLA3

-

Motor Power (kw):

-

3000 kw

-

Marketing Type:

-

New Product 2022

-

Metal stamping:

-

Hydraulic

-

High accuracy:

-

0.02mm

-

Mould supply:

-

can be supplied

-

After-sale service:

-

remote, on-site

-

Function:

-

Automatic, manual

-

Automation:

-

Configurable automated production line

-

Price:

-

Offer competitive prices

-

Security:

-

High security level

-

Energy saving:

-

25%-50%, low maintenance cost

-

Service life:

-

3-5 years longer than ordinary models

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Return Force (kN):

-

3000 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JianLong

-

Year:

-

2022

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Customized as required

-

Weight (T):

-

7.4 T

-

Model Number:

-

JLA3

-

Motor Power (kw):

-

3000 kw

-

Marketing Type:

-

New Product 2022

-

Metal stamping:

-

Hydraulic

-

High accuracy:

-

0.02mm

-

Mould supply:

-

can be supplied

-

After-sale service:

-

remote, on-site

-

Function:

-

Automatic, manual

-

Automation:

-

Configurable automated production line

-

Price:

-

Offer competitive prices

-

Security:

-

High security level

-

Energy saving:

-

25%-50%, low maintenance cost

-

Service life:

-

3-5 years longer than ordinary models

Product introduction

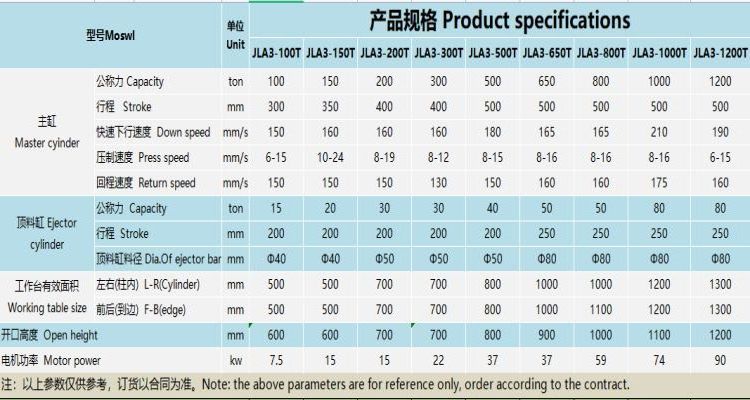

Hydraulic press parameter table

The parameter list is for customers' reference, we can also customize the machine size according to your requirements

Technical characteristics

Servo intelligent forging machine product features/advantages

Adopt servo system and touch screen operation interface, implement digital management; Low noise and high energy saving. Servo intelligent forging machine also has the following characteristics/advantages:

1) Pressure, stroke, pressure holding, cold and hot forging can be adjusted according to process requirements.

2) Column made of high strength alloy steel, hard chrome plating, good wear resistance, long service life.

3) The operating system supports three languages: Chinese, English and the customer's mother tongue.

4) According to the process requirements, can be set up cold extrusion printing or hot forging function, very flexible.

5) Can be customized, that is, according to different needs to customize different pressure hydraulic machinery;

6) Core electrical accessories are from Japan, Germany, the United States and Taiwan and other places.

7) Using servo motor oil temperature can be lower, temperature is guaranteed; Longer than ordinary machine life 3-5 years.

8) Easy to change the mold, shorter time to change the mold, improve the production capacity, less waste, save the source.

9) Equipped with induction function, automatic alarm and automatic troubleshooting system.

Scope of application

All kinds of bicycle handlebars stand forging; And a variety of special-shaped metal products extrusion forging process, but also according to different needs of stamping products in different industries, common stamping products are:

1) All kinds of bicycle handlebars are forged.

2) Hardware hardware parts fine blanking.

3) LED radiator, auto parts, mobile phone case, hardware tools and other cold extrusion and stamping molding.

4) metal and non-metal stamping or shallow tensile forming, etc.

Business recommend

Company profile

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city; Dongguan. The company is headquartered in Liaobu Town, Dongguan City, the company has established an international Business Division,

Offices in Guangxi, Shanghai and Hubei.

About us

Jianlong Hydraulic Machinery Co., Ltd. has more than 10 years of experience in hydraulic press research and development, design and manufacturing, always adhering to the "customer first forge ahead" service concept,

To provide our customers with fast and professional service! The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main production products:

Servo multi-directional (3D) forging press, servo four-column double action stretching hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die-casting trimming machine,

Servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shaped machine, hydraulic punch and other hydraulic equipment.

Our strength

The company has passed iso9001:2015 international quality, integrity management, after-sales service, CE and other system certification, the machines are exported to Mexico, Japan, South Korea, Vietnam, Australia, Malaysia, Pakistan and other countries

Part of the cooperation with customers display

Machine packing method

Normal packing is wooden case (size: L*W*H). Some national wooden cases will be fumigated.

To ensure machine safety, jianlong all machines are packed and fixed with PE film, and then shipped in wooden cases.

(Warm tips: the packaging process can accept customer video guidance, Jianlong mechanical packaging team will carry out personalized packaging according to customer needs)

FAQ

1. How much pressure can you provide for hydraulic machines?

We can supply machines of different tonnage from 5-5000 tons.

2.Our machine requirements are different from yours. Can we adjust the specifications?

Yes, all the specifications of our hydraulic presses can be customized according to customer's requirements.

3. What can your hydraulic machine do?

We have many different machines to handle different forging (cold and warm forging), deep drawing, stamping, molding, etc.

4. Can your hydraulic press be connected to robots or other automatic lines?

Yes, our machine can connect robot and automatic line, if you have this requirement, please inform us in advance to reserve the port.

5. if we have some special requirements, such as machine sliding table, machine heating, long time to maintain pressure, multi-layer, etc., is it ok?

Yes, all these requirements can be provided, if you have other requirements, please also contact us. Custom made machines are welcome.

6. What type of hydraulic press can you provide?

Four column/frame guide rail /C frame/horizontal structure/servo system/multi direction forging, we can provide these machines.

Hot Searches