- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

High

-

Voltage:

-

380V/ or by customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3700*2750*2900mm

-

Weight:

-

7500 KG

-

Function:

-

Washing Filling Capping

-

Advantage:

-

Automatic Working

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET PE

-

Keywords:

-

Liquid Filling Packaging Machine

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Feature:

-

Work Efficiently

-

Power supply:

-

220V/380V 50HZ

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic, Other

-

Filling Material:

-

Other, Water, Juice

-

Filling Accuracy:

-

High

-

Voltage:

-

380V/ or by customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3700*2750*2900mm

-

Weight:

-

7500 KG

-

Function:

-

Washing Filling Capping

-

Advantage:

-

Automatic Working

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET PE

-

Keywords:

-

Liquid Filling Packaging Machine

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Feature:

-

Work Efficiently

-

Power supply:

-

220V/380V 50HZ

Product Description

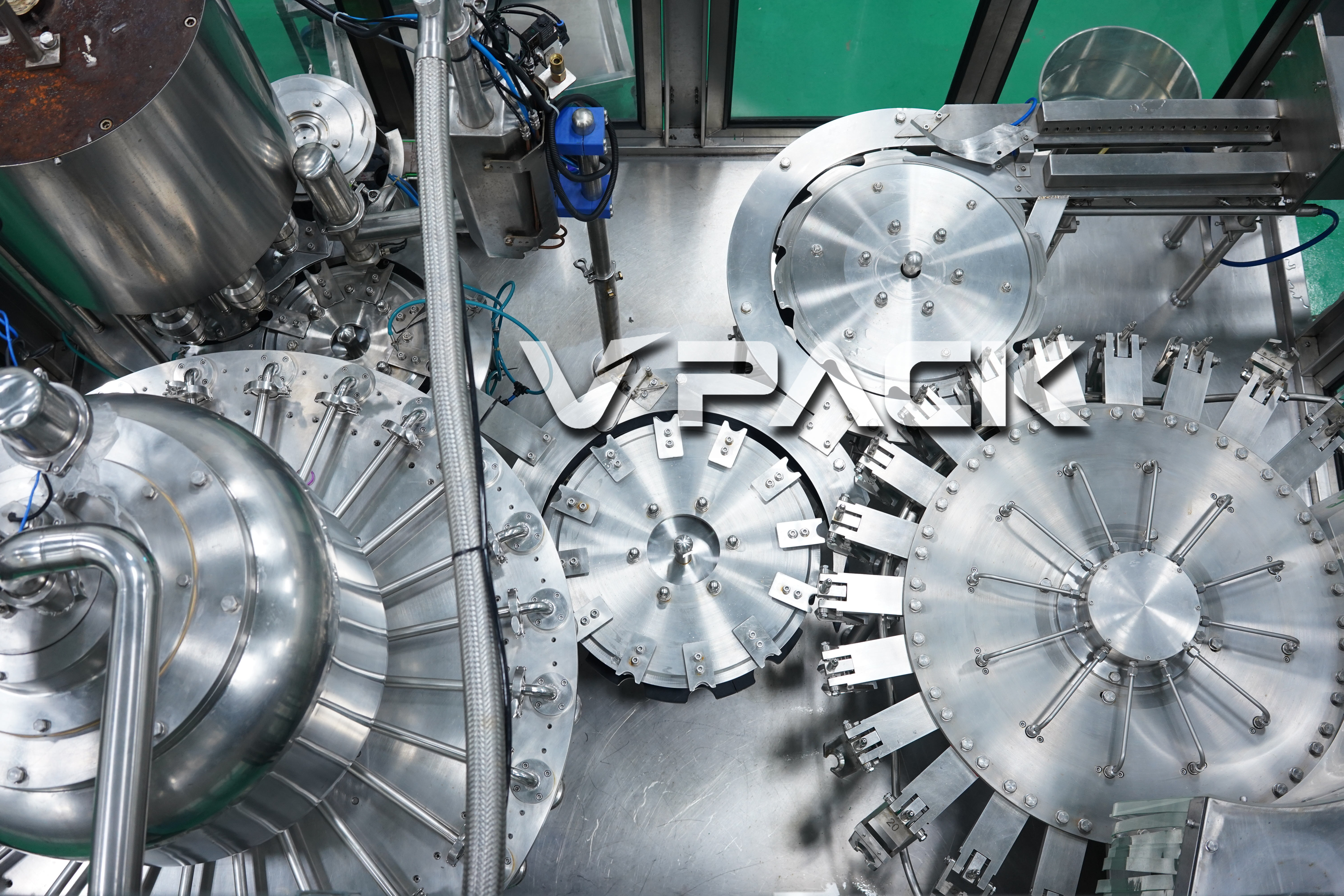

Juice Bottle Washing Filling Capping 3 in 1

The machine is mainly applied for the filling of beverage. Integrating with washing, filling and sealing, it realizes full automation in the whole process, suitable for polyester bottle and plastic bottle filling of juicedrink. The bottle types applicable for various parts are easily, conveniently and rapidly adjustable. It adopts hot filling, stable and reliable. Compared with the machines of the same specification, the productivity and benefit of this machine is larger.

Main Features

The machine adopts advanced SIEMENS programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectric inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

Machine Images

Product Paramenters

|

Model

|

Capacity

|

Rinsing heads

|

Filling heads

|

Sealing heads

|

Overall dimensions

|

|

RCGF14-12-5

|

3000BPH

|

14

|

12

|

5

|

2400*1900*2800mm

|

|

RCGF16-16-5

|

4000BPH

|

16

|

16

|

5

|

2500*1900*2200mm

|

|

RCGF18-18-6

|

6000BPH

|

18

|

18

|

6

|

2800*2050*2200mm

|

|

RCGF24-24-8

|

8000BPH

|

24

|

24

|

8

|

3100*2450*2800mm

|

|

RCGF32-32-10

|

12000BPH

|

32

|

32

|

10

|

3700*2750*2900mm

|

|

RCGF40-40-10

|

15000BPH

|

40

|

40

|

10

|

4300*3300*2900mm

|

|

RCGF50-50-12

|

18000BPH

|

50

|

50

|

12

|

5200*3700*2900mm

|

Washing heads.

<1>Into bottle way is air conveyor direct connection with Bottle dial .

<2>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

<3>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

<4> 304/316 stainless steel washing pump make the machine more durable.

<2>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

<3>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

<4> 304/316 stainless steel washing pump make the machine more durable.

Juice filling heads.

<1> We adopt the piston filling type to fill the pulp seperate with the juice.

<2> 304/316 Stainless steel high precision filling nozzle.

<3> Filling volume adjustable in fine rank, same liquid level after filling.

<4> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

<5> 304/316 stainless steel filling pump.

<2> 304/316 Stainless steel high precision filling nozzle.

<3> Filling volume adjustable in fine rank, same liquid level after filling.

<4> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

<5> 304/316 stainless steel filling pump.

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping.

<2> All 304/316 stainless steel construction

<3> No bottle no capping.

<4> Automatic stop when lack of bottle.

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .

<2> All 304/316 stainless steel construction

<3> No bottle no capping.

<4> Automatic stop when lack of bottle.

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .

Automatic shrink sleeve labeling machine

This machine adopts international advanced technology;cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body is designed.

This machine's structure is compact,and suitable for the production line of different direction and different height.

The machinery part adopts combination designing of modularization,and makes the machine resonable.The height

adjustment adopts motor fluctuating;it is convenient to replace the material.The special cutter head designing,make the

film-rolling cut more correct and reliable.

The machinery part adopts combination designing of modularization,and makes the machine resonable.The height

adjustment adopts motor fluctuating;it is convenient to replace the material.The special cutter head designing,make the

film-rolling cut more correct and reliable.

Cutter head unit

The new style cutting knife drived by servo motor, with high speed, more stable and precise, shrink perfectively. Synchronous locating device enables the tolerable error to ±1mm.Unit cutter head plane design in China which apply to the container of ∮30mm-∮130mm.You never need to change or debug it. Cutter head original transducer is inside the cutter head and when you take down cutter head, you donot need to correct the synchronous belt. It also has unique light touch human-machine screen.

Label feeding unit

It adopt double material shelf which enable the change of label more convenient and fast. There is label checking photoelectricity

and when there is no material, it will stop automatically and give alarm light and also display on the touch screen. It adopts

rotary potentiometer which enable the label feeding stable and fluent and avoid the error label length, label block and other

problem when label feeding servo convey the label.

Steam shrinking tunnel

The spout of steam use the separation style which make the tunnel smooth. The spout mouth is divided into four parts and the height ,place and quantity of steam of every part can be adjusted in order to make the shrink effect perfect .The low pressure steam bag use the seamless steel tube design and every connect tube use stainless steel soft tube ,so the disassembly and fixing is very convenient. The whole machine is made of stainless steel, so it is heat preservation and save energy sources.

|

Model parameters

|

TB-150

|

TB-250

|

TB-350

|

TB-450

|

|||

|

Capacity

|

6000-9000B/H

|

12000-15000 B/H

|

18000-24000 B/H

|

25000-30000 B/H

|

|||

|

Label type

|

φ50-97mm

|

|

|

|

|||

|

Bottle diameter

|

φ50-97mm

|

|

|

|

|||

|

Sleeve length

|

40-150mm

|

|

|

|

|||

|

Label thickness

|

≧0.035mm

|

|

|

|

|||

|

Label material

|

PVC/PET

|

|

|

|

|||

|

Main power

|

2.5KW(380V,50HZ)

|

|

|

|

|||

|

Diemsion

|

2440*890*2200mm

|

|

2440*990*2200mm

|

|

|||

|

Weight

|

650KG

|

750KG

|

750KG

|

850KG

|

|||

Automatic shrink film wrapping machine

This type of machine is suit for beverage, drinking water,beer wine and infusion bottle ect. packaging,which can be packed with shrink film .Package will be a firm and beautiful appearance. With stable function, and the packed articles tight and orderliness.

Main Features

Serve control technology can maintain the mechanism of precise synchronization of advanced, reliable delivery.

The heating box, reasonable structure, heat insulation, high precision of temperature control.

Supporting German Siemens, Germany P+F, Japan SMC, Italy motorcycle Rio, the world's most advanced control

System components, equipment, stable operation.Mechanical transmission components using after heat treatment of stainless steel or carbon steel and other materials; spraying the surface quality,The antirust performance.

The heating box, reasonable structure, heat insulation, high precision of temperature control.

Supporting German Siemens, Germany P+F, Japan SMC, Italy motorcycle Rio, the world's most advanced control

System components, equipment, stable operation.Mechanical transmission components using after heat treatment of stainless steel or carbon steel and other materials; spraying the surface quality,The antirust performance.

|

Model

|

Capacity

|

Shrink film thickness

|

Compressed air pressure

|

Compressed air comsuption

|

Conveyor height

|

|

VPK-150A

|

8~10 bags/min

|

80~90um

|

0.4~0.7Mpa

|

0.3M3 / MIN

|

1050 (mm)

|

|

Shrink film material

|

Package max size

|

Machine dimension

|

Machine weight

|

Electric power

|

Volatge

|

|

PE、PVC、POF

|

L420*W280*H350

|

6050×1280×2150 mm

|

1200kg

|

28 kw

|

customized

|

Other Products

Pre-process system

1.High-shear emulsifying tank + Plate heat exchanger

2.Mixing tank

3.UHT sterilizer + homogenizer machine + Buffer tank

4.Hot water system + Hot water tank

5.CIP cleaning system

2.Mixing tank

3.UHT sterilizer + homogenizer machine + Buffer tank

4.Hot water system + Hot water tank

5.CIP cleaning system

Our Machine Video

CO2 Laser printer

Shrink Sleeve Labeling Machine

Bottle Shrink Packing Machine

Our Company

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

|

Sales Manager

|

Jack Shao

|

|

Responsible for the project

|

CO2 & Fiber Laser Printer, Water purificaiton system, Water filling machine,Juice hot filling machine ,5 Gallon Water Production,Bottle blower...all kind of machine after-service

|

|

Responsible for the market

|

United Kingdom, Peru, Brazil, The Dominican Republic, Spain, Saudi Arabia,Thailand,etc

|

Recommend Products

Hot Searches