- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

zhengzhou

-

Brand Name:

-

Huamin, Huamin

-

Model Number:

-

rcgx191000 rngn150700 rngn120400 rnmn120700, rcgx191000 rngn150700 rngn120400 rnmn120700

-

Product name:

-

Ceramic insert

-

Material:

-

Cubic Boron Nitride

-

Usage:

-

Turning

-

Workpiece material:

-

cast iron roll, high speed steel roll, Carbide Rolls

-

Advantage:

-

High efficiency, wear-resistant

-

Application:

-

Rolls, slurry pumps, brake discs, bearings, etc.

-

Cutting Material:

-

Cast iron, hard steel, powder metallurgy

-

Payment:

-

T/T in advance 100%

Quick Details

-

Use:

-

External Turning Tool

-

Hardness:

-

HRC45-70

-

Coating:

-

uncoated

-

Place of Origin:

-

zhengzhou

-

Brand Name:

-

Huamin, Huamin

-

Model Number:

-

rcgx191000 rngn150700 rngn120400 rnmn120700, rcgx191000 rngn150700 rngn120400 rnmn120700

-

Product name:

-

Ceramic insert

-

Material:

-

Cubic Boron Nitride

-

Usage:

-

Turning

-

Workpiece material:

-

cast iron roll, high speed steel roll, Carbide Rolls

-

Advantage:

-

High efficiency, wear-resistant

-

Application:

-

Rolls, slurry pumps, brake discs, bearings, etc.

-

Cutting Material:

-

Cast iron, hard steel, powder metallurgy

-

Payment:

-

T/T in advance 100%

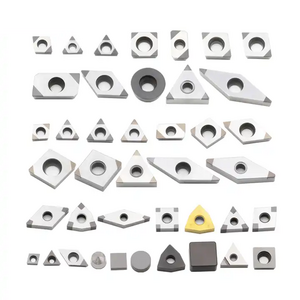

rcgx090700 Ceramic insert rcgx120700 Ceramic turning insert cnc tool cngn1204 sngn dngn1507 tngn1604 rngn1204 vngn cbn tool

Machining pass roll conventional

Ceramic insert

conical bottom and V-groove Model:

RCGX151000

rngn090400 rngn120400

rngn150700 rngn120700

RCGX060500 RCGX060600 RCGX080700 RCGX090700 RCGX120700RCGX191000.

Machining pass roll conventional

Ceramic insert

conical bottom and V-groove Model:

RCGX151000

rngn090400 rngn120400

rngn150700 rngn120700

RCGX060500 RCGX060600 RCGX080700 RCGX090700 RCGX120700RCGX191000.

Processing cast iron roll and high speed steel roll

Ceramic insert

:RCGX060500 RCGX090700 RCGX120700 RCGX151000 RCGX191000 RCGX201200

RCGV060500 RCGV090700 RCGV120700 RCGV151000 RCGV191000 RCGV201200.

Ceramic insert: mainly include alumina ceramic blades, silicon nitride ceramic blades, metal ceramic blades Features: Ceramic

tools have high hardness and good wear resistance, and are generally suitable for semi-finishing and finishing machining of

various cast iron parts and hardened steel parts with a hardness below HRC65. In the high-speed finishing of some precision

workpieces, the effect of using cars instead of grinding can be achieved! Advantages of silicon nitride ceramic tools 1. High

hardness, generally HRA93-94. Therefore, it has good wear resistance. It can process high-hard materials that are difficult or

impossible to process with traditional tools, such as various hardened steels with a hardness of HRC65 and Hardened cast iron.

Therefore, the power consumed by the annealing process can be exempted; and therefore, the hardness of the workpiece can also be

improved, and the service life of the machine equipment can be extended; 2. It is not only capable of roughing and finishing

high-hardness materials, but also milling, planing, interrupted cutting and rough turning of blanks with high impact; 3 Ceramic

inserts have small friction with metal during cutting. Cutting is not easy to stick to the insert, and it is not easy to produce

built-up edge. In addition, high-speed cutting is possible. Therefore, under the same conditions, the surface roughness of the

workpiece is relatively low. 4. The tool durability is several times or even dozens of times higher than that of traditional

tools, which reduces the number of tool changes during processing and ensures the small taper and high precision of the processed

workpiece; 5. High temperature resistance, good red hardness, continuous cutting at 1200°C, so the cutting speed of ceramic tools

can be much higher than that of cemented carbide. It can carry out high-speed cutting or realize "replacing grinding with turning

and milling". The cutting efficiency is 3-10 times higher than that of traditional cutting tools, achieving the effect of saving

man-hours, electricity, and the number of machine tools by 30-70% or more; rational use of ceramic cutting tools Although knives

have many advantages, their performance is brittle. In recent years, people have taken many measures from the manufacture, use and

sharpening of ceramic knives to suppress their brittleness, thus making ceramic knives enter the practical stage.

tools have high hardness and good wear resistance, and are generally suitable for semi-finishing and finishing machining of

various cast iron parts and hardened steel parts with a hardness below HRC65. In the high-speed finishing of some precision

workpieces, the effect of using cars instead of grinding can be achieved! Advantages of silicon nitride ceramic tools 1. High

hardness, generally HRA93-94. Therefore, it has good wear resistance. It can process high-hard materials that are difficult or

impossible to process with traditional tools, such as various hardened steels with a hardness of HRC65 and Hardened cast iron.

Therefore, the power consumed by the annealing process can be exempted; and therefore, the hardness of the workpiece can also be

improved, and the service life of the machine equipment can be extended; 2. It is not only capable of roughing and finishing

high-hardness materials, but also milling, planing, interrupted cutting and rough turning of blanks with high impact; 3 Ceramic

inserts have small friction with metal during cutting. Cutting is not easy to stick to the insert, and it is not easy to produce

built-up edge. In addition, high-speed cutting is possible. Therefore, under the same conditions, the surface roughness of the

workpiece is relatively low. 4. The tool durability is several times or even dozens of times higher than that of traditional

tools, which reduces the number of tool changes during processing and ensures the small taper and high precision of the processed

workpiece; 5. High temperature resistance, good red hardness, continuous cutting at 1200°C, so the cutting speed of ceramic tools

can be much higher than that of cemented carbide. It can carry out high-speed cutting or realize "replacing grinding with turning

and milling". The cutting efficiency is 3-10 times higher than that of traditional cutting tools, achieving the effect of saving

man-hours, electricity, and the number of machine tools by 30-70% or more; rational use of ceramic cutting tools Although knives

have many advantages, their performance is brittle. In recent years, people have taken many measures from the manufacture, use and

sharpening of ceramic knives to suppress their brittleness, thus making ceramic knives enter the practical stage.

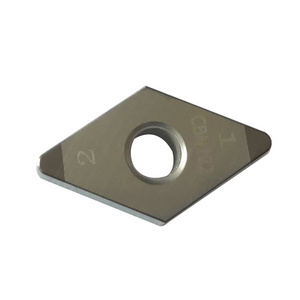

Product Description

|

Product Name

|

Solid cbn inserts

|

|

Main Ingredient

|

cubic boron nitride

|

|

Processing procedure

|

Roughing and finishing are available

|

|

machining workpiece

|

roll

|

|

Processing part

|

outer circle, groove

|

|

Advantage

|

Wear-resistant, long life, high efficiency

|

|

Common models

|

SNMN,RNMN,RCGX-V,RCGX-Y,RCMN,CNMN

|

|

Package

|

10pcs/box

|

Product Paramenters

Using Effects

HUAMIN CBN inserts can turn high speed steel rolls, cast iron rolls, high boron steel rolls, carbide rolls, rough and finish outer circles, grooves. compared with carbide inserts, can be processed at high speed, and the efficiency is increased by N times. Compared with other brands of CBN inserts, it has a longer life and higher durability.

For high hardness rolls, Huamin mainly recommends RNMN (RNGN), RCMX (RCGX)-Y/V, SNMN, CNMN solid CBN inserts.

Details Images

Q:How about the payment methods?

A:1)Recommending:Trade Assurance online order.

It is the most safety way for your payment and goods delivery.Supporting:TT, L/C,E-CHECKING,PAY LATER and so on.

2) TT by Proforma Invoice with Bank details.

3)Paypal and Western Union.

Q:Can you offer the sample firstly?

A:Yes, we can provide the best quality samples for you to test for free, but the shipping cost is borne by the buyer.

Q:How long is your delivery time?

A:For samples, it usually takes 2-3 days, for bulk order quantity, we will give you the exact time according to your specific order quantity.

Q:Can you supply non-standard cutting tools/PDC cutter/etc?

A:Of course, we can provide you with tailor-made services according to your specific requirements.

Q:Can we get the after-sale service?

A:Yes,we have professional after-sale service for you,including sample changes,product problem solving solution,prompt feedback online service,etc

Any other question, kindly feel free to let me know.

Hot Searches