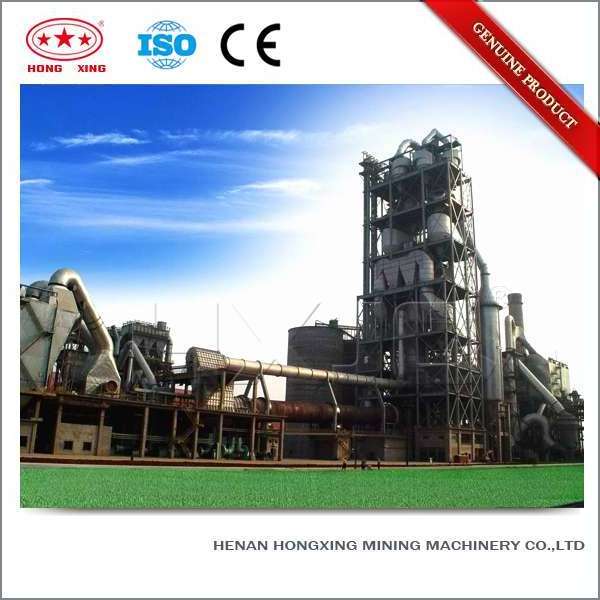

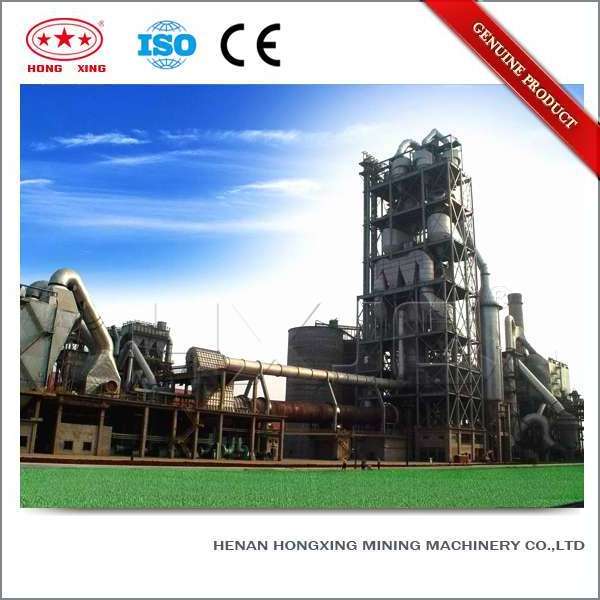

Active lime kiln is a kind of rotary kiln, which is the main equipment for calcining active lime. The equipment is composed of cylinder, supporting device, supporting device with hydraulic stop wheel, transmission device, lubrication device, kiln tail sealing device and other components. The rotary kiln has simple structure, reliable operation and easy automatic control of the production process.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

800-2000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10 t-2000t

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

HEN

-

Brand Name:

-

HXJQ

-

Power:

-

800-2000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10 t-2000t

Product Description

Introduction

Equipment Advantage

Advantage

Effectively improve the preheating effect, the decomposition rate of preheated limestone into the kiln can reach 20-25%, and can directly use 10-15mm fine-grained limestone

The reliable combined scale seal at both ends of the rotary kiln makes the air leakage coefficient less than 10%

The kiln lining uses composite refractory materials to reduce radiant heat loss

The rotary kiln has simple structure, reliable operation and easy automatic control of production process

Specification

|

item

|

value

|

|

Type

|

|

|

Application

|

Chemicals Processing, Plastics Processing

|

|

Condition

|

New

|

|

Place of Origin

|

HENAN

|

|

Brand Name

|

HXJQ

|

|

Power

|

Accroding to model

|

|

Dimension(L*W*H)

|

Accroding to model

|

|

Warranty

|

1 Year

|

|

Weight (KG)

|

10000

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining

|

|

Showroom Location

|

Egypt, Italy, France, Germany, Peru, Saudi Arabia, Indonesia, Spain, Thailand, Kenya, Argentina, South Korea, Sri Lanka, Romania, Nigeria

|

|

Marketing Type

|

Hot Product 2023

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Pump, Gearbox, Engine

|

|

Heating Method

|

Steam Heating

|

|

Material

|

SUS304, SUS304L, SUS316, SUS316L, Ti

|

|

|

|

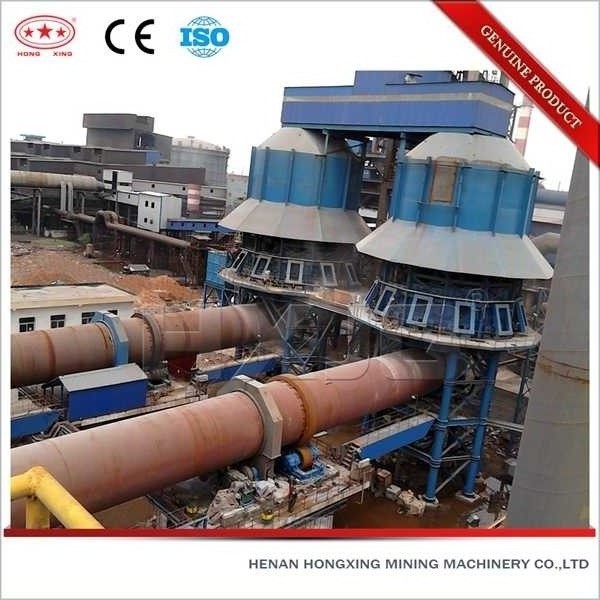

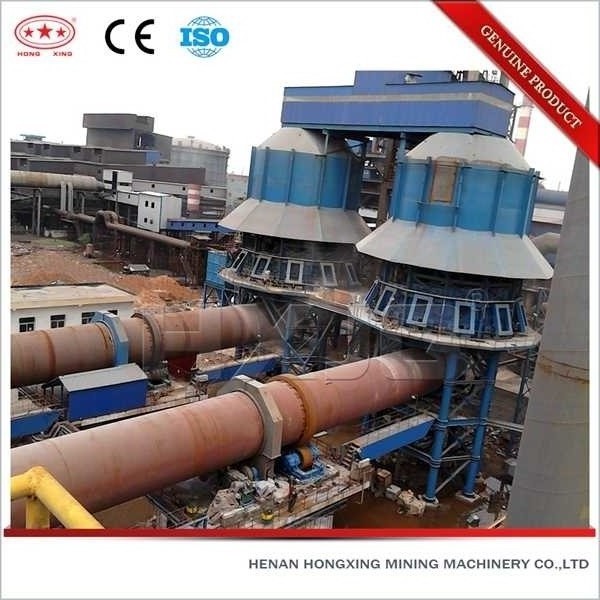

Work Principle

Qualified limestone is stored in the silo, lifted by the elevator and transported to the top silo of the preheater. At the top of the preheater, the feed amount is controlled by two level gauges above and below, and then the limestone is evenly distributed to each chamber of the preheater through the feed pipe.

The limestone is heated to about 900°C by the kiln flue gas at 1150°C in the preheater, about 30% of the decomposition is pushed into the rotary kiln by a hydraulic push rod, and the limestone is decomposed into CaO2 and CO2 by sintering in the kiln. The limestone generated after decomposition enters the cooler, which is cooled to below 100°C by the cold air pumped into the cooler, and the hot air of 600°C through the heat exchange enters the kiln and the gas is mixed and burned, and the waste gas enters the cold air through the induced draft fan into the bag dust collector, and then enters the chimney through the exhaust fan. The lime from the cooler is sent to the lime product warehouse by vibrating feeder, chain bucket conveyor, bucket elevator and belt conveyor. Whether to carry out screening and other processes according to customer requirements.

Technical Parameter

Packing & Delivery

1.Standard Sea Shipping Container

2. Main Machines wrapped by PP sheet , Motor & Bolts & V-belt packed in Plywood Box

Hot Searches