- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Auto Lens Edger

-

Model:

-

Automatic

-

Application:

-

Optical Equipment

-

Type:

-

Laboratory Optical Equipments

-

Function:

-

Calibration

-

Weight:

-

250KG

-

Usage:

-

Visual Inspection

-

Material:

-

Granite

-

Name:

-

Vision Tester

-

Certificate:

-

CE ISO

Quick Details

-

Place of Origin:

-

Guizhou, China

-

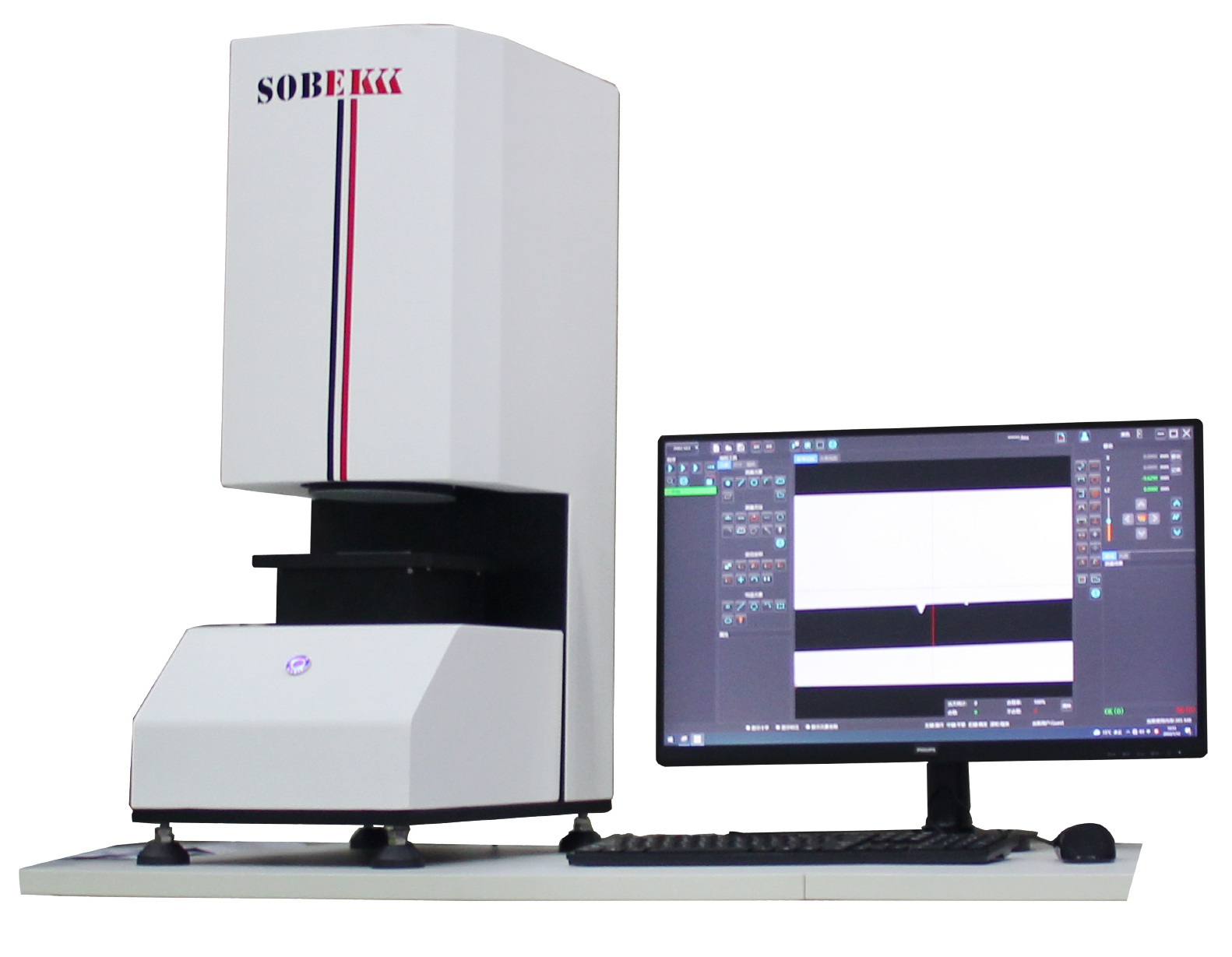

Brand Name:

-

Sobekk

-

Model Number:

-

QM180

-

Product name:

-

Auto Lens Edger

-

Model:

-

Automatic

-

Application:

-

Optical Equipment

-

Type:

-

Laboratory Optical Equipments

-

Function:

-

Calibration

-

Weight:

-

250KG

-

Usage:

-

Visual Inspection

-

Material:

-

Granite

-

Name:

-

Vision Tester

-

Certificate:

-

CE ISO

QM40

QM series instant video measuring machine, opticall instruments

Features

#image dimension measurement system features simple place and press operation , provides both incredible measurement speed and high measurement accuracy.

simply please a target on the stage and press the measurement start button, thwn system executes measurement of a number of points in the captures image in only seconds.

#No variation in measurement result among different operators

#when target edges are identified based on human vision , it is impossible to eliminate variation and errors caused by individual differences or skills levels , with the image dimension measurement system that detects edges automatcally, the measuremnet results is table and consistent regardless of operators.

#measurement results are automatically recorded and generate reports, all measurement resutlts and critical identifiiers are sutomatically recorded to simplify data management, then calculateds and displays critical statistical values,

# the instant vision measuring machine obtain an image of the part using its unique wide-field, high-precision telecenttric optical system, the telecentric optical system features constant image size regardless of height differences. karge depth-of field for sharp focus at various heights, and no image distortion despite part placement on stage.

Specification

| model | QM40 | QM110 | QM180 |

| measuring range(mm) | 42*35 | 110*75 | 180*130 |

| contour measuring accuracy | 1.5 | 3.0 | 3.5 |

| surface measuring accuracy | 2.0 | 4.5 | 5.0 |

| move device | Z axis electric lifting | ||

| image sensor | 20 megapixel ultra HDMI CMOS sensor | ||

| display | 27 inch HDMI monitor | ||

| optical lens barrel | double telecentric lens | ||

| move speed | 1s ( WITHIN 20 INCH) | ||

| light source | circular LED reflective light lens | ||

| coaxial reflective source | |||

| coaxial transmission light source | |||

#Improve work efficiency

put thge workpiece on the stage, press the button, auto focus, then press the button, got all the testing results in a second, anyone without special training can operate the machine.

#quick batch measuring

just put the workpiece on the stage, press the button, measure all datas, not only one workpiece at one time, several workpiece can be measured at the same time quickly, improve the work efficiency.

#avoid human error

different inspector same results

positioning quickly, No fixtures needed, put the workpiece on the stge randomly, within the vision of the machine, it can capture the targets and measure it quickly, No any human error.

one0time entire imaging, save times

#entire workpiece is visible

big vision range , entire workpiece imaging in one time, measure all positions in a very short time, improve work efficiency, save time and money.

#put the workpiece randomly, no fixtures needed

put the workpiece randomly, no fixtures needed

auto focusing, no need of fixtures, put the workpiece on the stage randomly, within he vision range of the machine, all positions can be measured in a very short time, no human error, improve the work efficiency.

#Adopts with low distortion telecentric lens

adopts with large depth field telecentric lens, excellent software algorithm, make sure the testing results are high preciison and accurate, avoid human error.

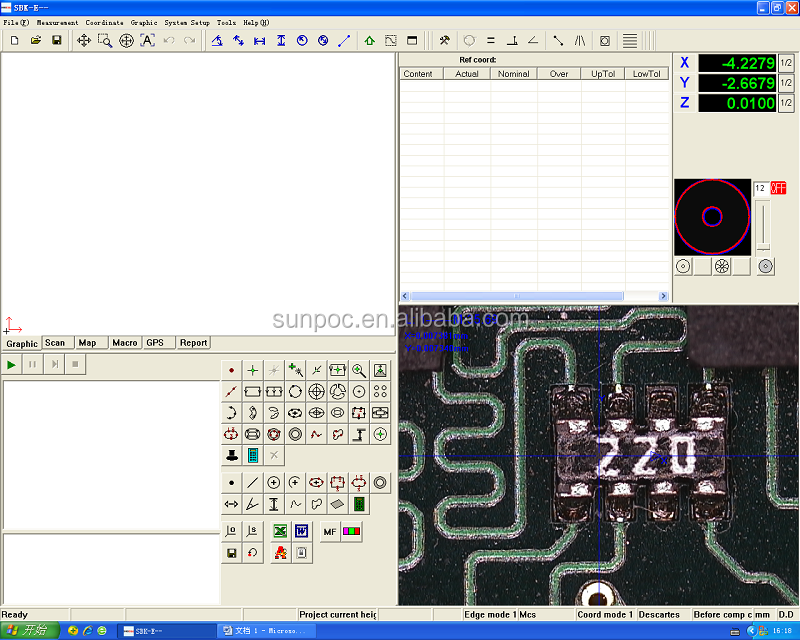

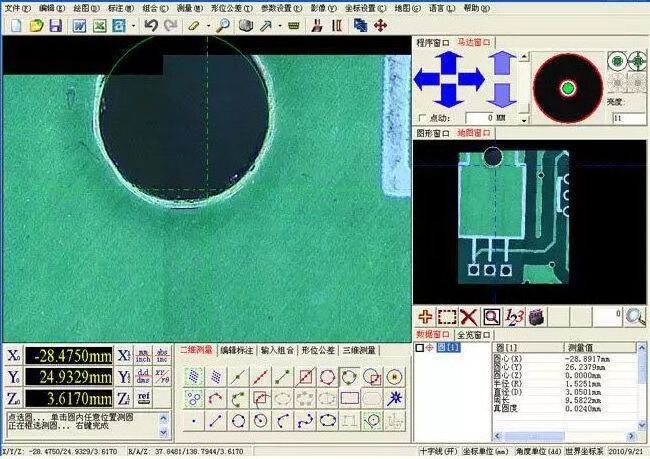

Software (SBK-INSPEC full automatic vision)

software main function

(compare with the standard CNC measuring software, this software without navigation function and joystick function)

#element measurement , it can measure 12 elements (point, line, circle,arc, ellipse, rectangle, groove, ring, distance, angle, open, cloud line, closed cloud line.)

#macro measurement function , to associate some of the measurement constuction commands to a butto, reduce the number of users to operate the mouise, improve work efficiency,

#automatric capture measurement, using the mouse circle to hold the edge of the workpiece, the line, circle or arc can be obtain automatiocally.

#elements structure, the construction of elements provides 10 construction m,ethods: translation, rotation, extraction, combination, parallelism, image recognition, symmetry, intersection

#rich displsy results, the measurement results of various element show that the amount of information is large enough to meet the needs of various customers

#can display optical magnification and screen magnification

#coordinate system, the multiple coordinate system can be set up according to drawing, and the coordinate transformation of each coordinate system can be realized,

Application

For more information on other workpiece measurement drawings and machine measurement usage, please contact rachel