The reverse osmosis can remove more than 97% of the soluble salt and above 99% of the colloid, microorganism, particles and organic materials, becoming the best first-choice choice equipment in the engineering of modern purified water, highly purified water and space water (super-purified water). The most highlighted features are low energy consumption, no pollution, simple technique, high-quality water and convenient operation and maintenance.

- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

0 g/s

-

Injection Weight (g):

-

1051 g

-

Screw diameter (mm):

-

70 mm

-

Weight (KG):

-

11500

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

170 mm

-

Power (kW):

-

30 kW

-

Name:

-

small plastic preform injection molding machine

-

Type:

-

Preform Injection

-

Application:

-

Preform, Cap, Cup, Box, Buckets, Spoon, Pipe Fitting..ect

-

Plastic Material:

-

PVC, PET, PE, PP..ECT

-

Clamping force:

-

1000-13000KN

-

Material:

-

Stainless Steel 304/316

-

Control:

-

Automatic

-

Electrical Equipment:

-

International brands

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Philippines, Peru, Pakistan, India, Malaysia, Australia, Morocco, Kenya, Colombia

-

Marketing Type:

-

Hot Product 2019

-

Clamping Force (kN):

-

3300

Quick Details

-

Ejector Stroke(mm):

-

680 mm

-

Ejector Force(kN):

-

91 kN

-

Theoretical Shot Volume(cm³):

-

1051 cm³

-

Injection Rate (g/s):

-

0 g/s

-

Injection Weight (g):

-

1051 g

-

Screw diameter (mm):

-

70 mm

-

Weight (KG):

-

11500

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

170 mm

-

Power (kW):

-

30 kW

-

Name:

-

small plastic preform injection molding machine

-

Type:

-

Preform Injection

-

Application:

-

Preform, Cap, Cup, Box, Buckets, Spoon, Pipe Fitting..ect

-

Plastic Material:

-

PVC, PET, PE, PP..ECT

-

Clamping force:

-

1000-13000KN

-

Material:

-

Stainless Steel 304/316

-

Control:

-

Automatic

-

Electrical Equipment:

-

International brands

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Philippines, Peru, Pakistan, India, Malaysia, Australia, Morocco, Kenya, Colombia

-

Marketing Type:

-

Hot Product 2019

-

Clamping Force (kN):

-

3300

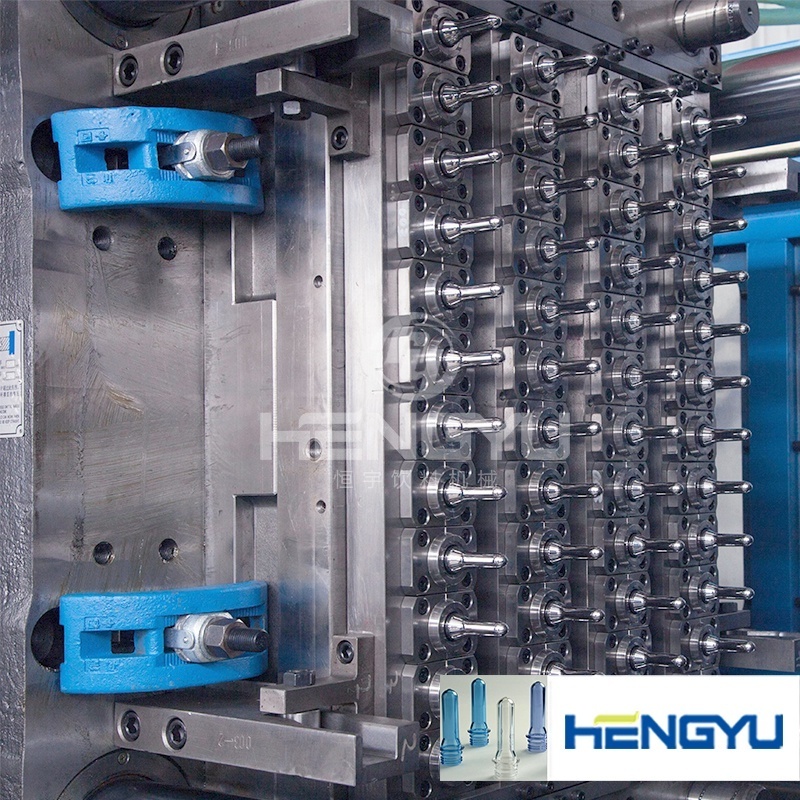

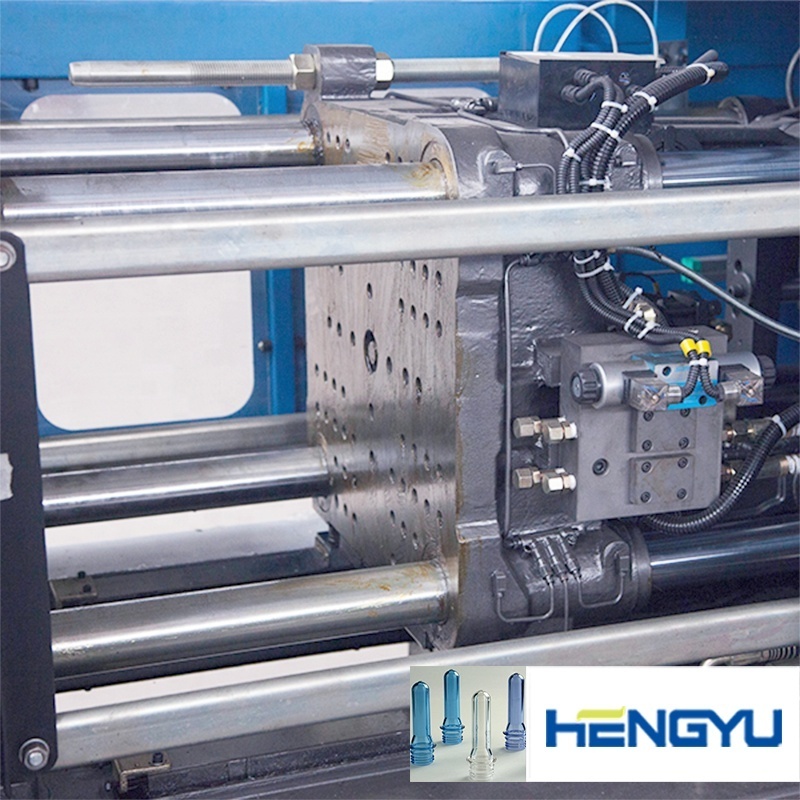

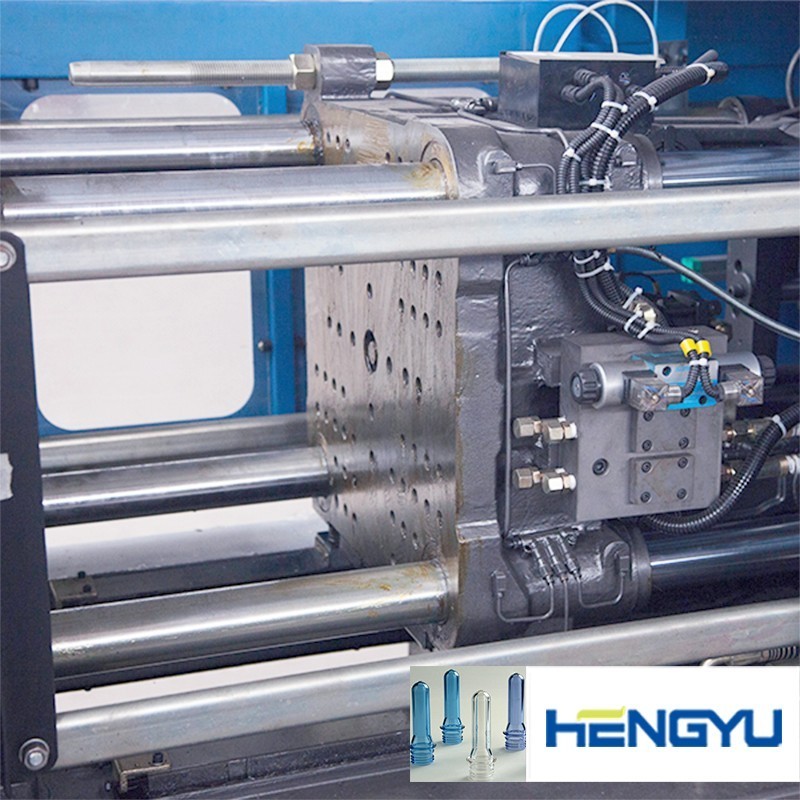

Heng Yu factory supply good quality small automatic plastic preform injection molding machinery

Product Detail

Adopting Europe technology, hydraulic unit adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators' safety.

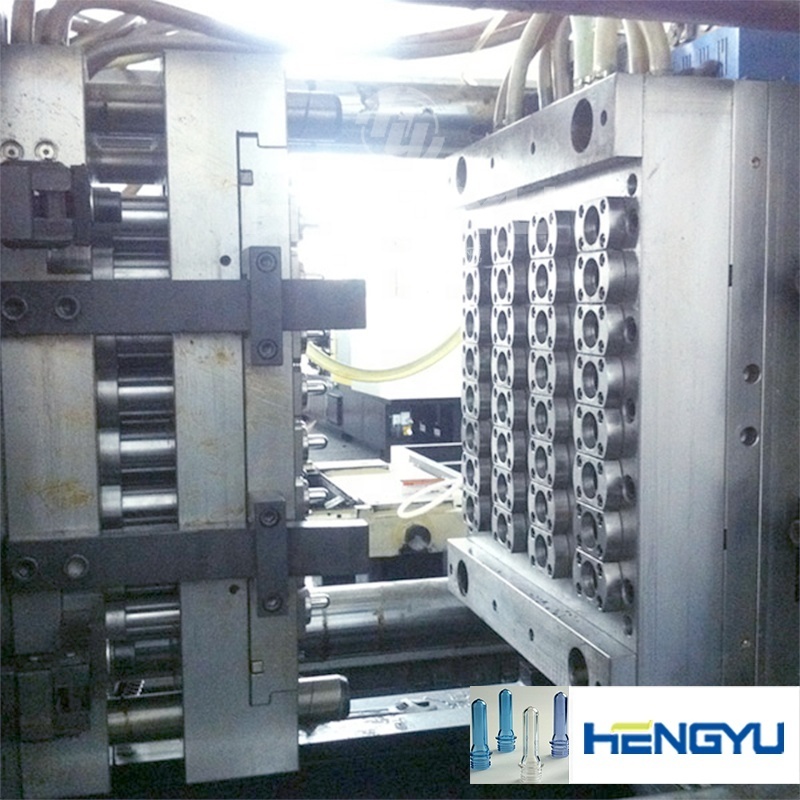

Clamping Unit

1.The design of equipment is logical, easily operation.

2.The automatic level is very high, the wage is very little.

3.Using famous imported hydraulic, electrical, sealing parts, the trouble is low.

4.No matter what the product's outside or inside, they can get the best guarantee, the good products rate can be above 99%

5 LCD computer control with big display screen

6 Hydraulic double proportional valve

7 Hard chrome plated high tensile strength steel tie bars

8 Generous space for fitting large moulds

9 Large opening stroke

10 Two position transducers to control Clamping and Injection

11 Four stages of injecting, independent velocity and pressure control

The Control Unit

1. Hydraulic mould height adjustment device

2. Screw cold-start prevention device

3. Melt decompression control

4. Screw back pressure control

5. Multiple hydraulic ejection

6. Differential high speed clamping

7. Centralized lubrication system

8. Low pressure mould protection device

9. Mechanical safety interlock

10. Double electrical safety interlock

11. Oil return filter

12. Oil tank with inner stainless steel container

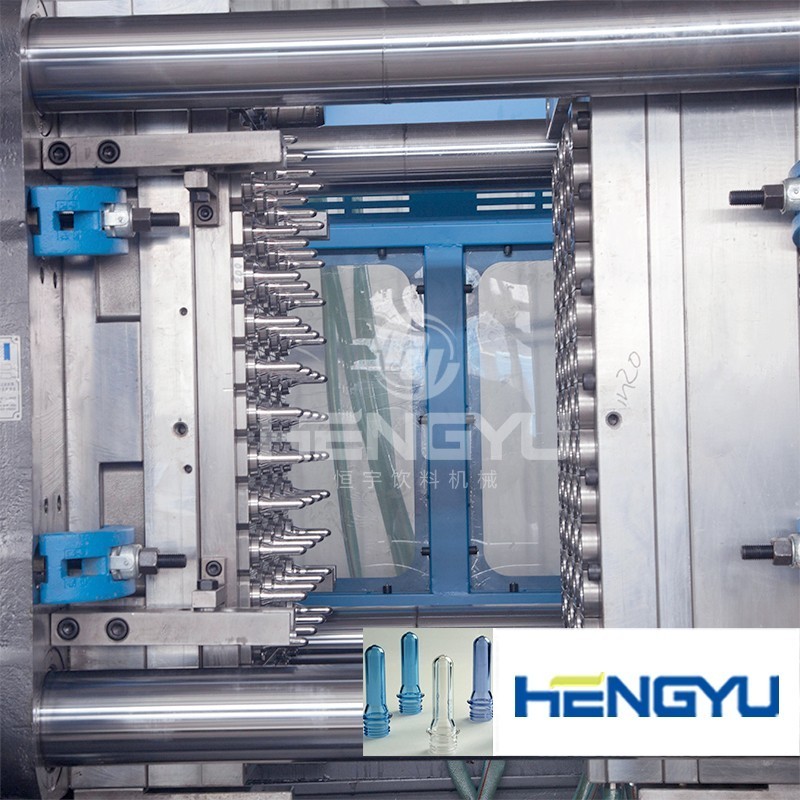

Advantages

The Application

The injection machine Benefits

▪Big diameter screw design and L/D ratio

▪High plasticization capacity

▪Four or above stages precise temperature PID control for barrel

▪Dehumidifying dryer selected for PET resin's special demands of removing moisture

▪Suitable for both varied pump and standard pump

Main Technological Parameters

|

Item

|

Unit

|

TIE-1600A

|

|

TIE-2400A

|

|

TIE-4800A

|

|

TIE-6500A

|

|

||||

|

Plasticizing Capacity

|

g / s

|

20.1 / 26.5 / 34.2

|

|

26.4 / 32.5 / 40

|

|

60.4 / 71.4 / 83.7

|

|

60 / 75 / 85 / 100

|

|

||||

|

Motor Power

|

kW

|

15

|

|

22

|

|

45

|

|

55

|

|

||||

|

Pump Pressure

|

Mpa

|

16

|

|

16

|

|

16

|

|

16

|

|

||||

|

Heating Power

|

kW

|

13.6

|

|

18.5

|

|

28

|

|

37.15

|

|

||||

|

Heating Zone

|

|

4

|

|

5

|

|

5

|

|

6

|

|

||||

|

Overall Size

|

m

|

5.3 * 1.35 * 1.9

|

|

6.2 * 1.6 * 2.1

|

|

7.5 * 2.1 * 2.45

|

|

9.3 * 2.3 * 2.7

|

|

||||

|

Net Weight

|

t

|

5.6

|

|

8.0

|

|

20

|

|

32

|

|

||||

|

Oil Tank Capacity

|

L

|

420

|

|

440

|

|

850

|

|

1200

|

|

||||

The flow chart of the water production line

Water Treatment System

1)Stainless steel high pressure film shell

2)All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3)Online type pressure auto self-protection device

4)Online type electricity indicator (with stable compensation)

5)System safe protecting and alarm system

6)System frame

Reverse Osmosis

Labeling Part

1)

Heat shrink sleeve labeling machine

2)

OPP Hot melt labeling machine

3)

PVC label stick labeling machine

The running of complete machine is stable and at high speed with the use of imported servo control system.Using of special bottle-distributing mechanism to avoid the materials being scrached and with which the machine can be adjusted and located quickly to label bottles with any diameter without replacing accessories.

Packaging Part

1)PE film shrink wrapping machine

2)Half-tray shrink wrapping machine

3)Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

The Company Introduction

The Company Development and Our Clients

The company general manager in an television interview

1. Installation and debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technicians of buyers should operate and maintain the equipment and debug some failures according to the seller's demand. If you could not solve the problems, we will guide you by phone; if the problems can not be solved, we will arrange our technicians to your factory to solve the problems.

Q1: How to choose the most suitable machine and get the final suitable price?

A1:

For beverage bottle Filling Machine, you need to reply us the following questions:

1. What kind of product (carbonated or no carbonated beverage, juice or water) for filling?

2. What's the volume of the bottle(Can)?

3. Could you show us picture of your Bottle/can?

4. Could you send some bottle samples to us?

5. What capacity do you need for production?

Q2: Do you have reference project?

A2:

We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information, you can go to visit their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city.

Contact our sales people you can get video of our reference running machine.

Q3: Do you provide customized service?

A3:

We can design the machines according to your requirements(material ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4: How long time for installation?

A4:

According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Q5: How to install the machine?

A5:

Please do not worry. We will send you detailed video and instruction manual for your reference. Customer also can appoint your engineers to our factory to learn. Our engineers also can go abroad to install the machine well, however, customer needs to pay round air tickets, hotel and service expenses.

Q6: Do you have videos or manual for us to know the machine better?

A6:

Yes, of course. Please email us and ask for it. We will send you soon.

Q7: How about your machine's quality?

A7:

Every machine is applied with CE certificate, SGS certificate, highly meets requirement of TUV, made of SUS 304 stainless steel for food packaging; SUS316 stainless steel for pharmaceutical products packaging. Inspect certificate is available.

Q8: What's the delivery time?

A8:

Depending on your order: for whole production line it is 40~60 workdays. bottle or tube filling machine, labeling machine, capping machine, unscrambling machine, can sealing machine will be 30~40 days. Other simple equipment will be around 20 days. The above delivery time is calculated after receiving the down payment as well as sample bottles / tubes and materials.

Q9: Is there MOQ for your machine?

A9:

1 set is acceptable. Of course, if you order more, it will be fine and its price will be more competitive.

Q10: What's your guarantee or the warranty of the quality if we buy your machines?

A10:

We offer you high quality machines with 1 year guarantee and supply life-long technical support.