- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

12 kw

-

Dimension(L*W*H):

-

8500*1600*2300 mm

-

Weight (KG):

-

5000

-

Evaporation Capacity(kg/h):

-

500-10000

-

Material:

-

Q235, Carbon Steel or stainless steel

-

Discount:

-

5% or more

-

Capacity:

-

0.5--10 tons per hour

-

Heating method:

-

Indirect heating

-

Heating source:

-

Coal, wood, steam, oil, diesel, gas, biomass fuel, etc

-

Color:

-

Blue/Red/Customization

-

Model:

-

HKB-1060

-

Usage:

-

Biomass Rotary Dryer Price

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HKB

-

Voltage:

-

380V

-

Power:

-

12 kw

-

Dimension(L*W*H):

-

8500*1600*2300 mm

-

Weight (KG):

-

5000

-

Evaporation Capacity(kg/h):

-

500-10000

-

Material:

-

Q235, Carbon Steel or stainless steel

-

Discount:

-

5% or more

-

Capacity:

-

0.5--10 tons per hour

-

Heating method:

-

Indirect heating

-

Heating source:

-

Coal, wood, steam, oil, diesel, gas, biomass fuel, etc

-

Color:

-

Blue/Red/Customization

-

Model:

-

HKB-1060

-

Usage:

-

Biomass Rotary Dryer Price

-

Certification:

-

CE ISO

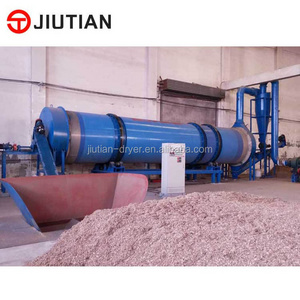

Industrial Bagasse Biomass Wood Chip Shavings Sawdust Rotary Drum Drying Dryer Machine Price

Biomass rotary dryer is widely applicable to straw press block fuel, charcoal machinery, sawdust pellet fuel, sawdust press block, farming and animal husbandry engineering etc. industry. Such as Sawdust drying, coffee bean dregs(waste coffee bean) drying, corn straw drying, soybean straw drying, cotton straw drying, wheat straw drying, sorghum culm drying, wood chips drying, ginkgo biloba drying, mulberry leaves drying etc. agricultural cellulose category etc, materials.

Inside of the biomass rotary dryer, there are many tubes. During drying process, the hot air will enter into tube-internal by draught fan, while the materials exist tube-external, so that the materials can be dried indirectly, there is no pollution and no color change, also a fire that caused by too high temperature will be avoided successfully.

1. New technology of indirect-drying structure, the working process is very safe and health.

2. Biomass rotary dryer equipped with biofuels stove, has a high environmental protection effect.

3. High thermal efficiency, the thermal efficiency can reach 60%.

4. The effect of drying is very good.

5. High output and low cost, reasonable design.

6. Coconut dryer moth-proofing, and it prevent mildew, has a long shelf life.

7. Coconut drier have a high degree of automation, easy to operate, save manpower.

| Model(mm) | HKB-1060 | HKB-1290 | HKB-1590 | HKB-2090 | ||

|

Dimension(mm) |

9000×1500×2000 | 12000×1700×2200 | 12000×2000×2500 | 12000×2500×2800 | ||

| Output(t/h) | 0.5-1 | 2-5 | 5-10 | 10-20 | ||

| Power(kw) | 12 | 18.7 | 25 | 30 | ||

| Weight(t) | 6 | 10 | 14 | 20 | ||

| Pipe range(m) | 6 | 9 | 9 | 9 | ||

| Diameter of pipe(m) | 1 | 1.2 | 1.5 | 2 | ||

| Dust catcher | Diameter(m) | 1 | 1.2 | 1.5 | 1.5 | |

| Height(m) | 1.8 | 2.2 | 2.5 | 2.5 | ||

| Adjustable speed motor | 4P-4KW | 4P-4KW | 4P-5.5KW | 4P-7.5KW | ||

| Hot air furnace | Inside diameter (mm) | 1500 | 1800 | 2000 | ||

| Gas output(Nm³/h) | 1200-1600 | 1500-2100 | 1750-2500 | |||

| Main air blower | Y5-47-5C-5.5KW | Y5-47-5C-7.5KW | ||||

| Dust removing fan | 4-72-3.2A-2.2KW | 4-72-3.6A-3KW | ||||

| Speed(r/min) | 3-5 | |||||

| Reduction of moisture(%) | 40-50 | |||||

| Dryness of finished materials(%) | 5-10 | |||||

| Heating medium | Hot clean air | |||||

| Hot air temp(℃) | <120 | |||||