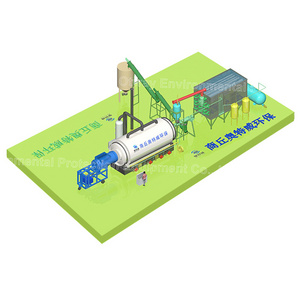

Mainly processing Raw material:

Used tyre, used plastic(PE, HDPE,LDPE,PP,PS)

Oil sludge, Oil Mud, HFO( Heavy fuel oil)

Mainly Processing:

Feeding--Pyrolysis--Cooling--Oil collection --Smoke cleaning--Carbon discharging & wire discharging