- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

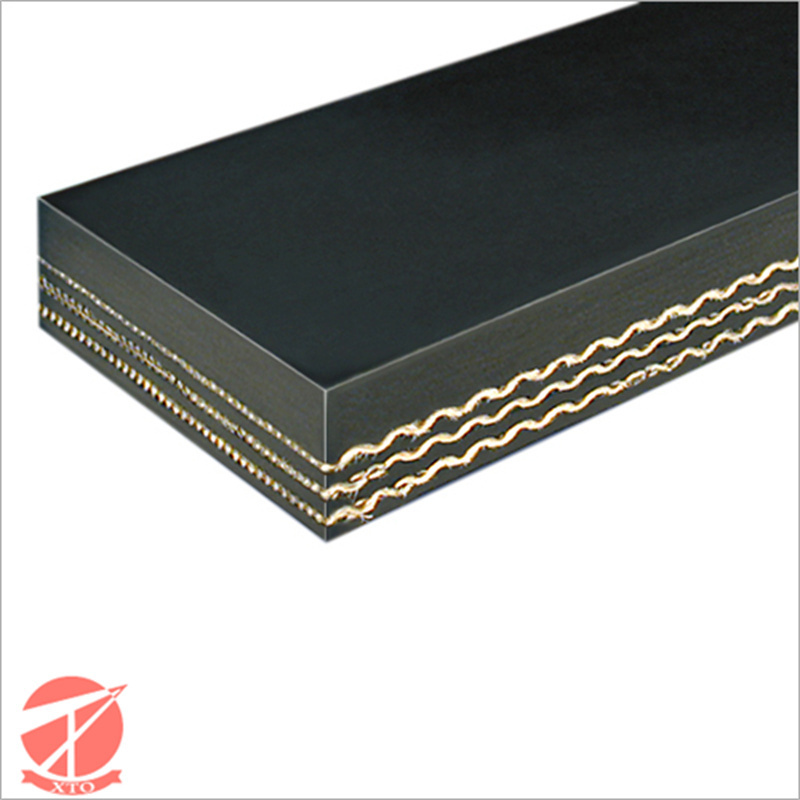

EP250

-

Material:

-

Rubber,Polyester,Nylon

-

Width:

-

500-2400mm

-

Length:

-

Customized Length

-

Operating Temperature:

-

-45℃ to 180℃

-

Tensile Strength:

-

300-2000N/mm

-

Abrasion Resistant:

-

Excellent

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XTO

-

Model Number:

-

EP250

-

Material:

-

Rubber,Polyester,Nylon

-

Width:

-

500-2400mm

-

Length:

-

Customized Length

-

Operating Temperature:

-

-45℃ to 180℃

-

Tensile Strength:

-

300-2000N/mm

-

Abrasion Resistant:

-

Excellent

We produces high-quality stable conveyor belts, and the product performance meets the requirements of DIN, RMA, AS,JIS,BS and so on.Can be developed and produced according to customer requirements.

Usage

Anti-adhesion conveyor belts are widely used for conveying in industries as electricity, coal, steel, ports, cement, chemical industries, etc. which will clay, nickel ore, sand, coal and other viscous materials not easy to adhere onto the belt thus keep the belt clean.

Characteristics

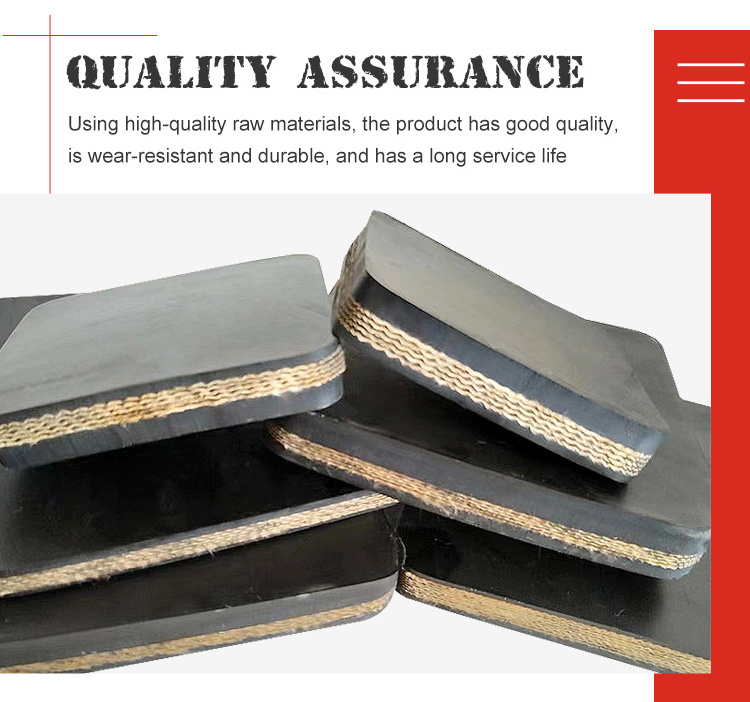

1.Low free energy and low polarity on the belt surface, difficult to adhere, easy to clean

2.Aging resistant, adapt to climate change, anti-static

3.Long service life

Standard Specifications

|

Strength(KN/m)

|

No. Of Piles

|

Carcass Type

|

Belt Width

|

|

300

|

2-4

|

NN/EP

|

500-2400mm |

|

400

|

2-4

|

NN/EP

|

|

|

500

|

2-5

|

NN/EP

|

|

|

630

|

3-6

|

NN/EP

|

|

|

800

|

3-6

|

NN/EP

|

|

|

1000

|

3-6

|

NN/EP

|

|

|

1250

|

3-6

|

NN/EP

|

|

|

1400

|

3-6

|

NN/EP

|

|

|

1600

|

4-6

|

NN/EP

|

|

|

2000

|

4-6

|

NN/EP

|

|

Note: It can be customized according to customers’ requirements.

Covers grades

|

Grade |

Tensile strength

min. (ISO37) Mpa |

Elongation at break

(ISO37) % |

Abrasion

max. (ISO4649) mm³ |

|

DAAS

|

15

|

400

|

150

|

The values will help to determine the appropriate cover compound for the application or for the

materials carries. Reliable assessment of the behavior of the covers in service for wear and cut

resistance cannot be determined from tensile strength, and abrasion values alone.

PS:The above standards are in accordance with Chinese standards, and can be customized according to the standards provided by customers.Such as DIN-X,Y,W,RMA-1,RMA-2.

Perfect Testing Equipment

We have a strong ability to develop new products. The company has an area of 3800 square meters of scientific research building.Four rubber material laboratories have been established, including material testing, formula testing, rubber mixing test and finished product testing, truly realize the strict control testing from raw materials to finished products, to ensure that the quality of products to meet the needs of us.

We are proud to have established long-term partnerships with many outstanding companies. These partners come from different industries, such as mining, manufacturing, logistics and transportation. For example, Ordered by BHP, RIO-TINTO, VALE repeatedly.We are committed to providing customers with efficient and reliable material handling solutions, and through close cooperation, we realize the sharing of resources and complementary advantages, and create greater value for customers.

Recommend Products

Hot Searches