- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Product name:

-

Hot Sale Small Capacity Ball Mill For Quick Lime Cement Plant

-

Application:

-

Limestone, Dolomite, Gypsum powder making plant

-

Capacity:

-

5-100tph

-

Spare Parts Supply:

-

Supply at lowest price

-

After-sales Service:

-

Life-long service

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Processing Materials:

-

Limestone, Gypsum, Clinker, Gold ore, etc.

Quick Details

-

Capacity(t/h):

-

2-100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNISHINE

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Product name:

-

Hot Sale Small Capacity Ball Mill For Quick Lime Cement Plant

-

Application:

-

Limestone, Dolomite, Gypsum powder making plant

-

Capacity:

-

5-100tph

-

Spare Parts Supply:

-

Supply at lowest price

-

After-sales Service:

-

Life-long service

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Processing Materials:

-

Limestone, Gypsum, Clinker, Gold ore, etc.

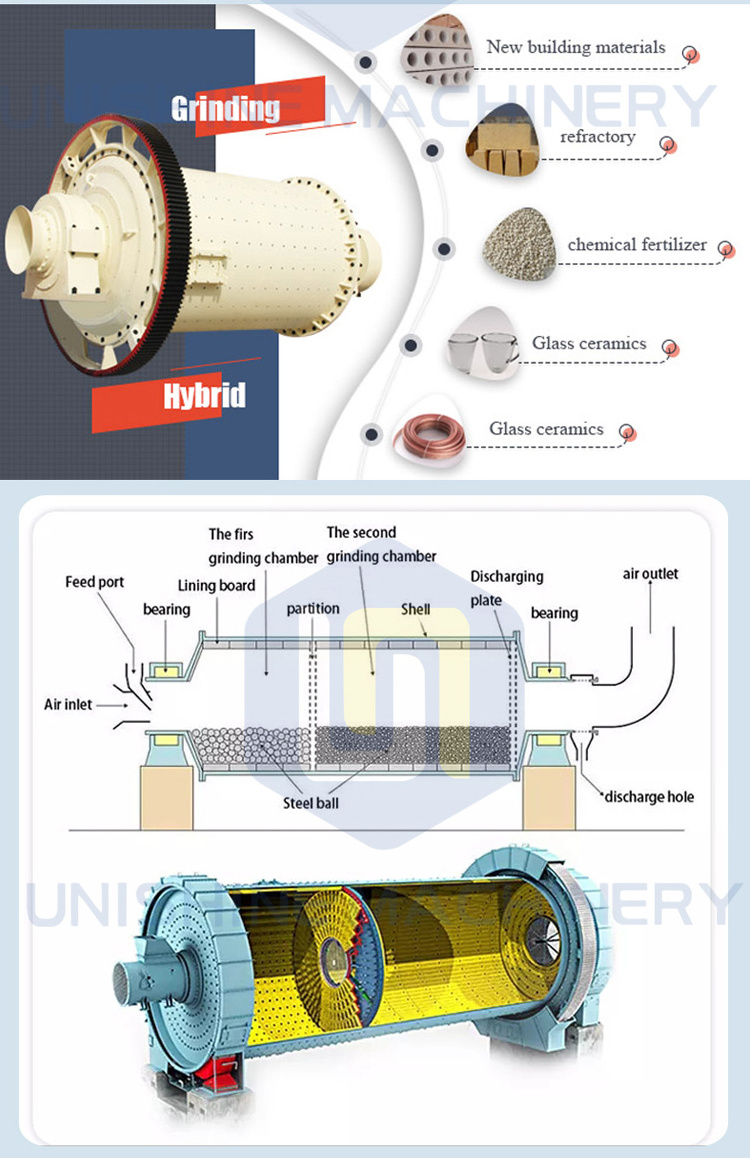

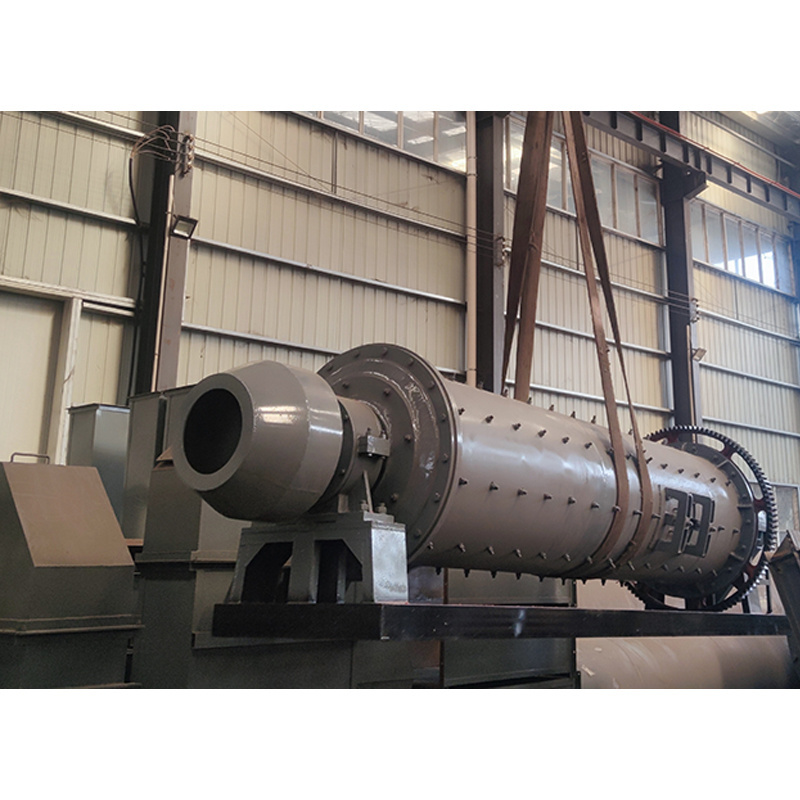

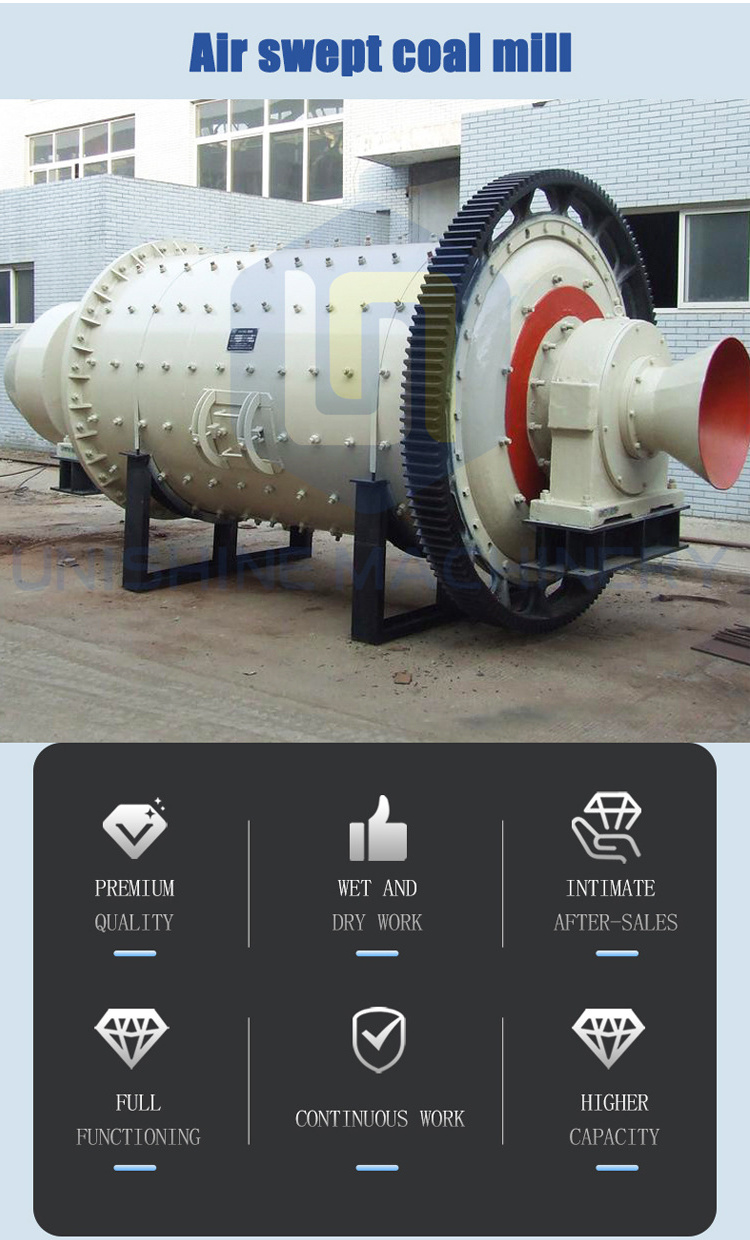

Air swept coal mill

Capacity: 0.65-615t/h

Applicable materials: Lignite, coal gangue, anthracite, etc.

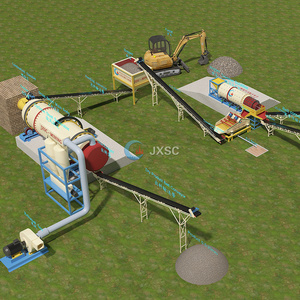

Application: Cement, building materials, thermal power generation, metallurgy, chemical industry, etc..

Brief Introduction: The air swept coal mill is used for grinding and drying coal of various hardness, it is widely used in cement, building materials, thermal power generation, metallurgical industry, chemical industry, etc.

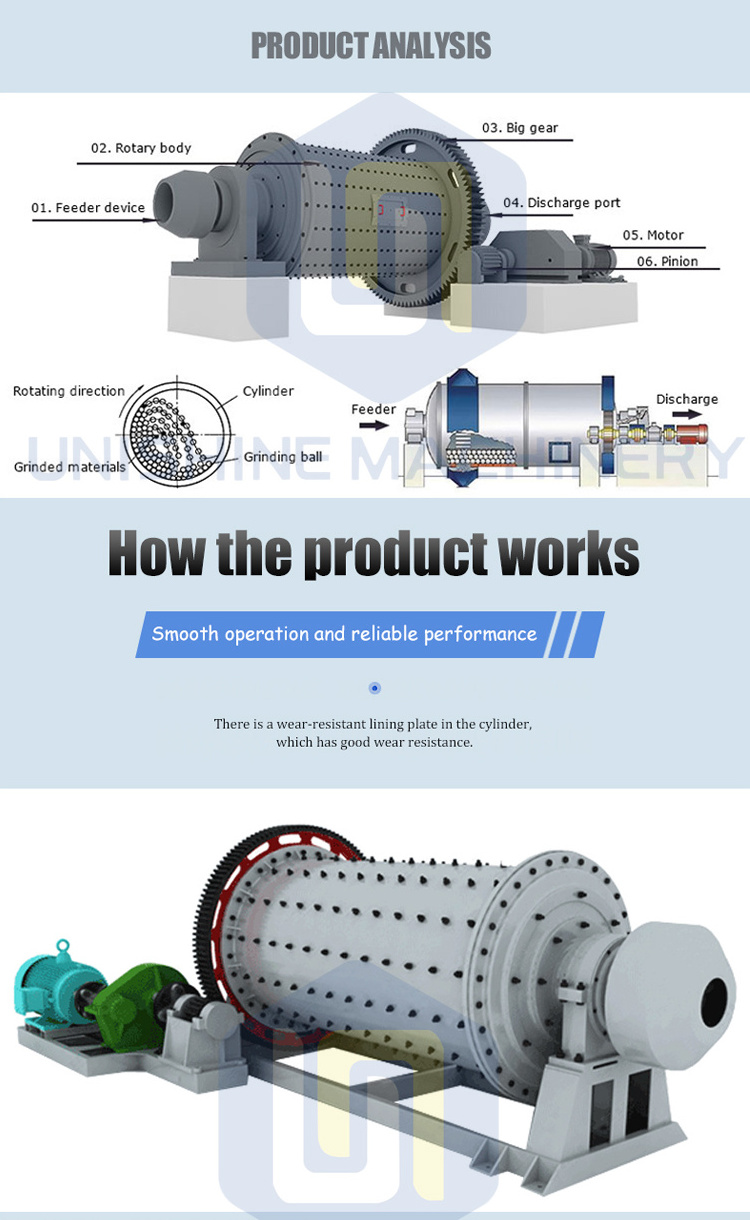

Introduction

Air-swept coal mill, also called coal mill, is an equipment used to grind and dry coal of various hardnesses. It is mainly used to grind lignite, coal, anthracite, coal gangue and other raw materials. It is mainly composed of a feeding device, a main bearing, a rotating part, a transmission device, a discharging device, a high-pressure starting device and a lubrication system. It is widely used in cement, building materials, thermal power generation, metallurgical industry, chemical industry, etc. The air swept coal mill has a reasonable structure and high grinding efficiency. It is an ideal equipment for coal powder preparation.

Characteristics

1. Reliable operation, continuous working and large production capacity.

2. Optimize the support system, improve the lubrication structure, and reduce the system resistance.

3. Reduce the power consumption per unit output and save 20-30% of the electricity.

4. The ratio of steel balls is reasonable, and the output is increased by 15%-25%.

5. Adopt new material liner to increase wear resistance, prolong the service life of liner, reduce the number of replacement of wearing parts, and save maintenance cost.

6. The feeding device adopts the louver structure with inclined air inlet, which enhances the heat exchange capacity of the mill and effectively prevents the material blockage at the inlet of the coal mill.

7. Advanced control system, smooth start and transmission, good safety performance.

|

Specification (mm) |

Ball loading

|

Rotating speed

|

Capacity

|

P ower (KW) |

Voltage

|

Motor model |

Weight

|

|

Φ1200×2400 |

4.8 |

32 |

1.4-2 |

45 |

380 |

Y280M-8 |

12.2 |

|

Φ1500×3000 |

8 |

28.8 |

2-3 |

95 |

380 |

JR125-8 |

17.8 |

|

Φ1700×2500 |

7.5 |

24.5 |

3-5 |

95 |

380 |

JR116-6 |

1.7 |

|

Φ2200×3000 |

13 |

22 |

5-6 |

180 |

380 |

JR136-8 |

40.3 |

|

Φ2400×4750 |

22 |

20 |

10-12 |

280 |

6000 |

YR400-8 |

52.3 |

|

Φ2900×4700 |

35 |

18.6 |

16 |

570 |

6000 |

JSQ1512-6 |

76.5 |