- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

TANPU

-

Voltage:

-

380V

-

Power:

-

25KW

-

Weight:

-

5000 kg

-

After-sales Service Provided:

-

Engineers

-

Product name:

-

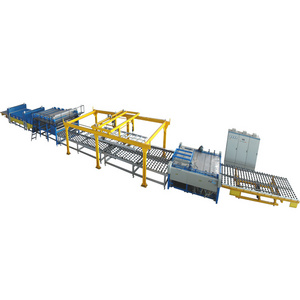

Glass Laminating Autoclave

-

Function:

-

Make Laminated Glass

-

Usage:

-

Laminated Glass Making

-

After Warranty Service:

-

1year

-

Keyword:

-

Window Glass Making Machine

-

Type:

-

CNC Automatic

-

Brand:

-

TANPU

-

Features:

-

Great Stability

-

Certification:

-

CE Certificate

Quick Details

-

Machine Type:

-

Glass Laminating Machine

-

Glass Thickness:

-

4-19mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

China

-

Brand Name:

-

TANPU

-

Voltage:

-

380V

-

Power:

-

25KW

-

Weight:

-

5000 kg

-

After-sales Service Provided:

-

Engineers

-

Product name:

-

Glass Laminating Autoclave

-

Function:

-

Make Laminated Glass

-

Usage:

-

Laminated Glass Making

-

After Warranty Service:

-

1year

-

Keyword:

-

Window Glass Making Machine

-

Type:

-

CNC Automatic

-

Brand:

-

TANPU

-

Features:

-

Great Stability

-

Certification:

-

CE Certificate

|

型号/Model

|

最大玻璃/Max Glass

|

最小玻璃/Min Glass

|

玻璃厚度/Thickness

|

运行速率/Speed

|

夹层线功率/Laminated power

|

高压釜功率/Autoclave power

|

|

TP-JC2050

|

2000*5000mm

|

300*420mm

|

4-80mm

|

0-2.5m/min

|

130.8KW

|

153.5KW

|

|

TP-JC2560

|

2500*6000mm

|

300*450mm

|

4-80mm

|

0-2.5m/min

|

147.3KW

|

180.5KW

|

|

TP-JC3080

|

3000*8000mm

|

300*450mm

|

4-80mm

|

0-2.5m/min

|

181.2KW

|

238KW

|

|

TP-JC33120

|

3300*12000mm

|

300*450mm

|

4-80mm

|

0-2.5m/min

|

211.4KW

|

559KW

|

|

Basic Technical Data

|

|

|

|

|

||||

|

Production Performance

Max glass size: 2500mm×6000mm Min glass size: 400mm×450mm Product thickness: 6mm ~ 80mm Glass thickness: 2.8~19mm |

|

|

|

|

||||

|

Production capacity

Working cycle of autoclave: 3.5-4 hours , 1 cycle/8h Loading capacity of autoclave: 300 m2 ( 2000X2000mm,4G+0.38PVB+4G) Speed of lamination line: average 4 min/piece |

|

|

|

|

||||

|

Electric Power

Total power supply: 380VAC, 3P+N+PE, 50Hz, 420KVA Including: lamination line: 360KVA, compressor system: 60KVA |

|

|

|

|

||||

|

Water and Air

Water supply: max. 0.6m3/min, pressure≧ 3kgf/m2 (water pool capacity min. 20cbm) Compressed air: 0.5 ~ 0.8MPa |

|

|

|

|

||||

|

Equipment List

|

|

|

|

|

||||

|

Main Equipment of Laminated Line

|

|

|

|

|

||||

|

Item

|

Description of equipments

|

|

Model

|

QTY

|

||||

|

001

|

Semi- Automation Laminated Glass Production Line (TP-JCX2560C)

Including following sections |

|

|

|

||||

|

|

JCX-1 Washing and Drying Machine

|

|

TP-QXJ25

|

1 set

|

||||

|

|

JCX-2 Spreading

(Laminator) Machine

|

Lay-up Position

Conveyor

|

TP-HP2560C

|

1 set

|

||||

|

|

|

Laminating machine

|

|

1 set

|

||||

|

|

|

Semi-Auto movable

sucking hanger

|

|

1 set

|

||||

|

|

|

PVB spreader

|

|

1 set

|

||||

|

|

|

Transition conveyor

|

|

1 set

|

||||

|

|

JCX-3 Forced Convection Pre-pressing Machine

|

|

TP-CYJ25

|

1 set

|

||||

|

002

|

Glass Autoclave (Ф2.85x6m,Chinese Standard)

|

|

TP-BGF2860

|

1 set

|

||||

|

Peripheral Equipment of Laminated Line (Optiona)

|

|

|

||

|

Item

|

Description of equipments

|

QTY

|

||

|

001

|

Assistant equipments for glass autoclave

Including following sections:

1. Air Compressor

Capacity: 7.5 m3/min

Pressure:1.3 MPa

Power: 75P (55 kw)

Quantity: 1 pc

2. Drying Machine

Capacity: 10 m3/min

Dew Point of pressure: 35~46 °F

Temperature on Entry: ≤176° F

Quantity: 1 pc

3. Filter (1µ, 0.01µ)

Capacity:16 m3/min

Quantity: 2 pcs

|

1 set

|

||

|

002

|

Air storage tank : (3 m3 Max. pressure = 1.3 MPa )

|

1 set

|

||

|

003

|

Ferry ,rails and trolleys

1.Trolleys, for Autoclave

Ferry: 3050x2000mm=1pc

Small trolleys: 2500x1750x2220mm=2pc

2. 15Kg/m RAI L:36m;

3. Silicone plate: 40x8mm=147m

|

1 set

|

||

|

004

|

Installation pipes, water pumps, valves for autoclave

|

1 set

|

||

|

Working Process of the Lamination Line

|

|

|

|

|

||||

|

For flat laminated glass (PVB film)

Loading by hand → Washing → Assemble by sucker → Pre-heating and pressing →Unloading by hand→ High pressing into autoclave→ Final product |

|

|

|

|

||||

|

For bent laminated glass (PVB film)

Washing → Assemble by sucker → Vacuum in autoclave→ High pressing in autoclave → Final product |

|

|

|

|

||||

|

General Features of Laminated Line

|

|

|

|

|

||||

|

Control System of Full Line

The whole line adopts PLC centralized control, HIM display and monitoring. A multi-level security protection, closed-loop feedback, timely according to the actual working condition, automatic regulation paragraphs speed. The overall design reasonable, beautiful, easy operation, components choose excellent. |

|

|

|

|

||||

|

Washing and Drying Machine

It equips with high quality washing brush which can wash coated glass and low-e glass. The glass has no black spot after washing. The thickness of the glass is available from 3mm to 40mm. The top frame can be lift by 450mm for convenient maintenance. |

|

|

|

|

||||

|

Spreading (Laminator) Machine

The PVB film is spreaded by hand. |

|

|

|

|

||||

|

Pre-pressing and Heating Section

The structure of Pre-pressing machine is reasonable, the operation is simple. The main transmission adopts frequency control, gear transmission, using quartz tube heating. Two big roller of pressing and heating furnaces have a synchronization transmission, the clearance of the two big rollers is adjusted by PLC control system, ensure the accuracy. |

|

|

|

|

||||

|

Forced Convection Glass Autoclave

High pressure section uses forced convection glass autoclave, PLC automatic control, HIM interface, ensuring safety ,reliable, high efficiency and energy saving. 1. Adopting advanced partition heating, graded cooling structure, with forced convection system, achieves truly energy saving, high efficiency. 2. The advanced PLC control system and HIM interface makes the operation simple and convenient 3. TPC (Thermal processing control) software, makes whole work be clear at a glance. The software contains: process control, data exchange, security protection, quality control, alarm output, etc. |

|

|

|

|

||||

1.Who are we?

TANPU INTELLIGENT is a design and fabrication oriented company for Flat Glass Deep processing technology. We are based on Guangdong, China, start from 2015, sell to Eastern Europe(30.00%), South America(20.00%), Southeast Asia(20.00%), North America(10.00%), Mid East(10.00%), Southern Europe(10.00%). There are total about 5-10 people in our office.

2.When can we arrange shipment?

We usually arrange shipment within 30 days after getting deposit, but customized machines should be between 60~100 days.

3.How to provide after-sales service?

Free warranty for one year. Provide remote services and video guidance.

4.What operating language is the machine?

Standard English, can also be changed as required

5.How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us for engineer

dispatching.

6.How can I contact you?

You can contact us directly on Ali International platform or add WA:008613703234074 or yt-machinery@vip.163.com.

7.Can l have a sample?

Yes, we can provide you with samples, but you need to pay the price of individual samples.

TANPU INTELLIGENT is a design and fabrication oriented company for Flat Glass Deep processing technology. We are based on Guangdong, China, start from 2015, sell to Eastern Europe(30.00%), South America(20.00%), Southeast Asia(20.00%), North America(10.00%), Mid East(10.00%), Southern Europe(10.00%). There are total about 5-10 people in our office.

2.When can we arrange shipment?

We usually arrange shipment within 30 days after getting deposit, but customized machines should be between 60~100 days.

3.How to provide after-sales service?

Free warranty for one year. Provide remote services and video guidance.

4.What operating language is the machine?

Standard English, can also be changed as required

5.How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us for engineer

dispatching.

6.How can I contact you?

You can contact us directly on Ali International platform or add WA:008613703234074 or yt-machinery@vip.163.com.

7.Can l have a sample?

Yes, we can provide you with samples, but you need to pay the price of individual samples.

Hot Searches