- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FUNIK

-

Model Number:

-

RNGN/RNMN/RCGX/RCMX/CNMN/SNGN

-

Material:

-

Cubic Boron Nitride

-

Certifications:

-

ISO9001, ISO14001, ISO45001

-

Grade:

-

FBN

-

MOQ:

-

10 Pieces

-

Machining model:

-

Rough/Semi-finishing/Finishing

-

Application:

-

Roll/Gear/Brake disc/Brake drum, ect

-

Workpiece:

-

Cast iron/Hardened steel/Cemented steel, etc

-

Cutting fluid:

-

Dry cut/wet cut

Quick Details

-

Usage:

-

Turning Tool

-

Hardness:

-

Super hard

-

Coating:

-

Uncoated, coated

-

Warranty:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FUNIK

-

Model Number:

-

RNGN/RNMN/RCGX/RCMX/CNMN/SNGN

-

Material:

-

Cubic Boron Nitride

-

Certifications:

-

ISO9001, ISO14001, ISO45001

-

Grade:

-

FBN

-

MOQ:

-

10 Pieces

-

Machining model:

-

Rough/Semi-finishing/Finishing

-

Application:

-

Roll/Gear/Brake disc/Brake drum, ect

-

Workpiece:

-

Cast iron/Hardened steel/Cemented steel, etc

-

Cutting fluid:

-

Dry cut/wet cut

Product Description

FUNIK CBN inserts are widely used in processing pearlitic cast iron, high chromium and nickel alloy cast iron, hardened steel, powder metal, hard alloy and super alloy. In the mechanical machining application of the traditional system, not only it has greatly reduced the comprehensive production cost, but also significantly improved the production capacity and efficiency during the whole production operation, and the equipment investment is greatly decreased at the same time.

Our Advantages

√ Excellent cost performance

The service life of Funik CBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of Funik CBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

√ High machining efficiency

The machining efficiency of Funik CBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

√ Excellent surface quality

Surface finish and dimensional precision of machining workpiece of Funik CBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

√ Strong universality

Funik CBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

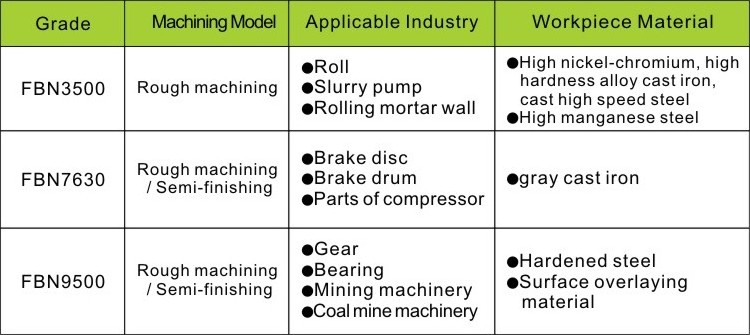

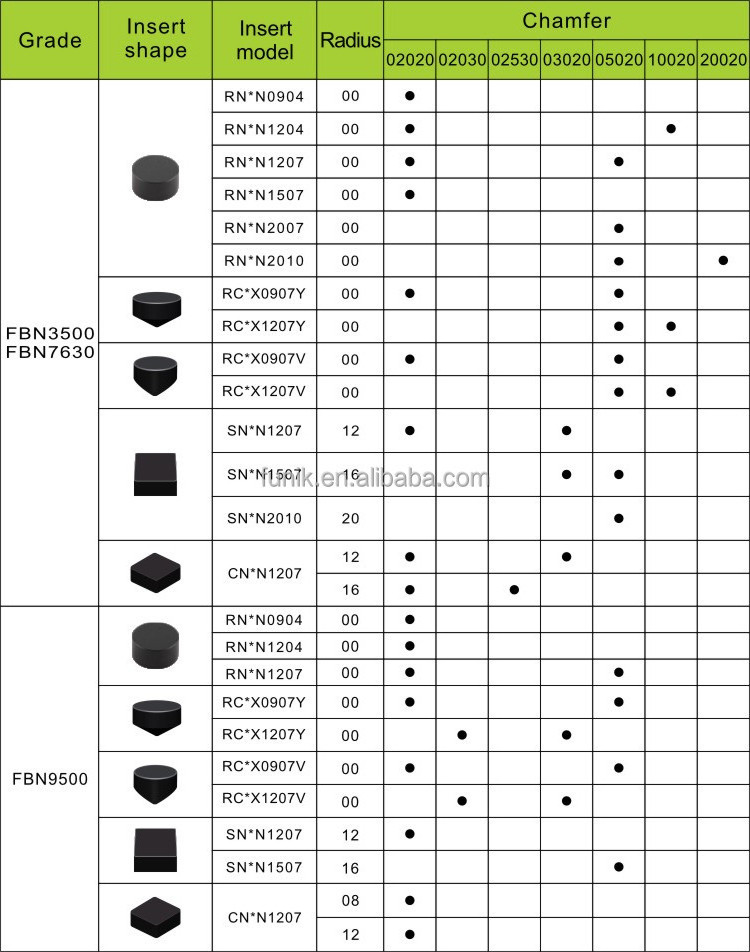

FBN Impact-resistant Solid Insert

FBS Brazed Solid Tip Insert

|

Grade

|

Machining model

|

Applicable industry

|

Workpiece material

|

|

FBS7630

|

Rough machining/ Semi-finishing

|

●Brake disc

●Brake drum

●Parts of compressor

|

●Gray cast iron

|

|

FBS9500

|

Rough machining/ Semi-finishing

|

●Gear

●Bearing

● Mining machinery

● Coal mine machinery

|

●Hardened steel

●Surface overlaying material

|

FBK Single-layer brazed Coated Insert

|

Grade

|

Machining model

|

Applicable industry

|

Workpiece material

|

Cutting fluid

|

|

FBK7510 C07

|

Finishing

|

●Brake disc

|

●Gray cast iron

●Case hardened alloy

|

Dry cut or wet cut

|

|

FBK7520 C07

|

Finishing

|

●Brake disc

●Gear

|

●Gray cast iron

●Powder metallurgy

|

Dry cut or wet cut

|

|

FBK9540 C06

|

Finishing

|

●Gear

●Bearing

|

●Hardened steel

|

Dry cut or wet cut

|

|

FBK9550 C06

|

Finishing

|

●Gear

●Bearing

|

●Bearing steel

●Cemented steel |

Dry cut or wet cut

|

|

FBK9560 C06

|

Finishing

|

●Gear

●Bearing

|

●Cemented steel

|

Dry cut

|

Multiple Choice

CBN Solid Inserts:

RNGN, RNMN, RCGX, RCGO, SNMN, CNMN, TNGN, RCMN, RCMX, SCGN, DNUN, WNMN

Manufacturing & Inspetion Process

Application

Funik CBN inserts are used for turning and milling of centrifugal rolls, slurry pumps, brake discs, brake drums, rolling mortar walls, compressor parts, gears, bearings, mining machinery, coal mining machinery industries.

Package & Shipping

Why Choose Us

FAQ

Q1: Are you trading company or manufacturer?

We are the world's leading manufacturer of superabrasives, superhard composites and superhard cutting tools since 1988 (ISO9001/ISO14001/ISO45001 certificated).

Q2:What is your main market?

Our market is mainly in Europe, America and Asia. Now we are working with many world top 500 companies, including 3M, TOYOTA, GM, Saint-Gobain, Mitsubishi, SUMITOMO, Panasonic and Samsung etc.

Q3: Is customization available?

Yes. We can OEM the products with your requirements.

Q4: What is your delivery way and delivery time?

Normally the delivery time is 1-2 weeks and the delivery way is by air.

Q5: Are samples available for quality test?

Yes. We can provide sample for quality test.

Hot Searches