- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HANNA

-

Voltage:

-

customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Material of powder coating room:

-

PP or PVC

-

Reciprocator:

-

Design matching

-

Lighting:

-

LED

-

Powder recovery equipment:

-

Big cyclone fast automatic color change equipment

-

Powder recovery rate:

-

98%

-

Powder recovery time:

-

10-15 mins

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE/ISO9001

-

Curing oven temperature:

-

Consistent and stable

Quick Details

-

Machine Type:

-

FA, Spray Booths, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Other

-

Warranty of core components:

-

2 Years

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HANNA

-

Voltage:

-

customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Material of powder coating room:

-

PP or PVC

-

Reciprocator:

-

Design matching

-

Lighting:

-

LED

-

Powder recovery equipment:

-

Big cyclone fast automatic color change equipment

-

Powder recovery rate:

-

98%

-

Powder recovery time:

-

10-15 mins

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE/ISO9001

-

Curing oven temperature:

-

Consistent and stable

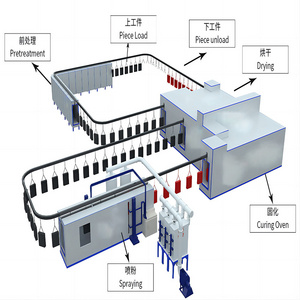

Product Type

One Stop Solution, Turnkey Solution for Powder Coating Plant

Pre-Sales Service:

* Inquiry and consulting support.

* Design Program support.

* View our Factory.

After-Sale Service:

* Installation & Commissioning & Training

* Engineers available to service machinery overseas.

* Free spare parts are provided

Pre-Sales Service:

* Inquiry and consulting support.

* Design Program support.

* View our Factory.

After-Sale Service:

* Installation & Commissioning & Training

* Engineers available to service machinery overseas.

* Free spare parts are provided

|

Equipment

|

|

|

Application

|

|

|||

|

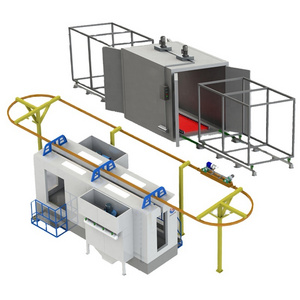

Washing cleaning pretreatment system

|

|

|

Dipping tank / Bath spraying

|

|

|||

|

Drying oven

|

|

|

150mm Rock wool insulation material; Diesel,gas ,electric as heating energy

|

|

|||

|

Powder coating equipment

|

|

|

Quickly color change cyclone powder coating booth; Filter recovery powder coating cabin

|

|

|||

|

Curing oven

|

|

|

batch oven, 150mm insulation thickness

|

|

|||

|

Conveyor system

|

|

|

Manual slidding conveyor, semi automatic trolley

|

|

|||

Product Description

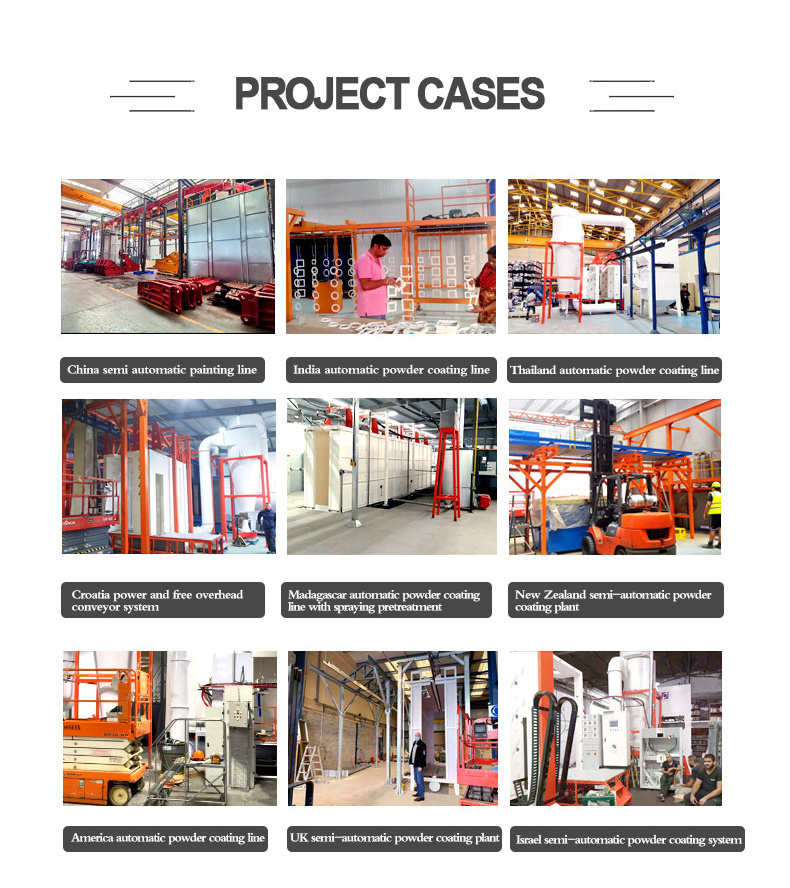

Case Stories

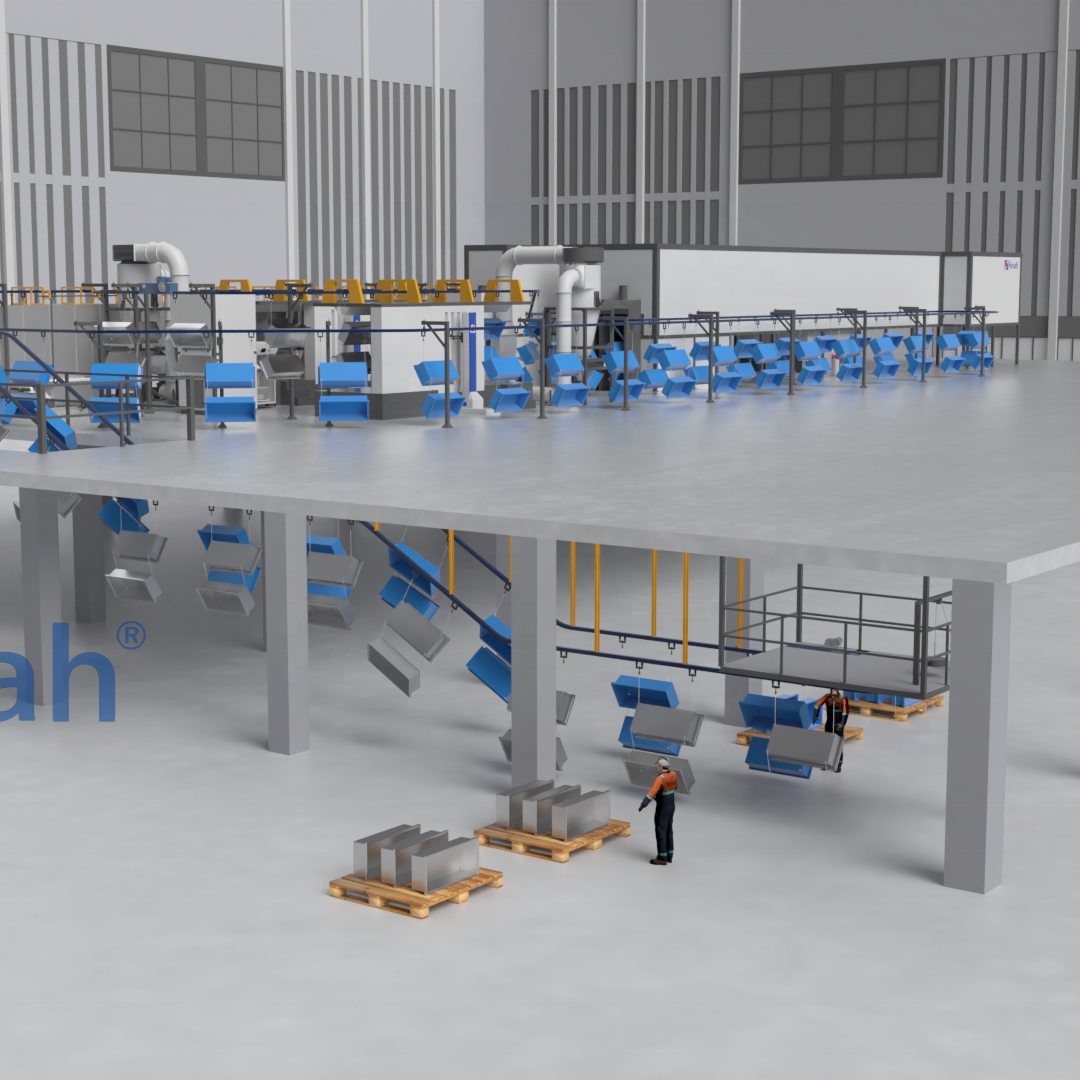

HANNA is a specialist in lifting virtually all types of projects in the business of industrial surface treatment lines.

Having worked with and supplied to almost all industries, we have a unique knowledge of and experience with meeting a very wide range of operational and spatial requirements.

We have installed more than 4800 lines worldwide, and we have chosen some of the references to be described in detail.

Click on the brands to see the case stories with descriptions of the customer product and finishing system.

See the range of industries we work with and our references in these industries.

Having worked with and supplied to almost all industries, we have a unique knowledge of and experience with meeting a very wide range of operational and spatial requirements.

We have installed more than 4800 lines worldwide, and we have chosen some of the references to be described in detail.

Click on the brands to see the case stories with descriptions of the customer product and finishing system.

See the range of industries we work with and our references in these industries.

Installation site

About Us

Hebei Hanna Powder Coating Equipment Technology CO., LTD has over 29 years rich experiences of the R&D and manufacturing in China,From simple hand coating through to fully automated powder coating. Our products are designed for you to customize the automatic spraying assembly line;

These include: Electrostatic spraying machine,Electrostatic spraying gun,Automatic elevating equipment,quick change of color powder room,Powder recovery equipment,Multi-function spray room, Spray paint room, telescopic

spray paint room, Pretreatment equipment, spray, hot air furnace, biological granule combustion machine, gas burner, electric heating oven, curing oven, chain suspension conveying equipment, etc. And through to CE, ISO 9001 standards.

spray paint room, Pretreatment equipment, spray, hot air furnace, biological granule combustion machine, gas burner, electric heating oven, curing oven, chain suspension conveying equipment, etc. And through to CE, ISO 9001 standards.

Hebei Hanna Technology Co.,Ltd.

A Professional Powder Coating Equipment Manufacturer welcome to visit at any time!

Visit customers

Cooperation Customers Of Hebei Hanna Technology Co.,Ltd.

Packaging & Shipping

FAQ

Are you a trader or a factory?

We are manufacturer and exporter. Our own factory was found in 1990,Our export office was established in 2014.

What should I provide if interested in your powder coating equipment ?

A.The material/size(max)/weight(max)of your workpiece.

B.How many of your daily output(one day=8hours,one month=30days)?

C.What heating power do you prefer: electric,gas, diesel or coal?

D.The size of your factory(length, width and height)?

How to ensure the quality of the equipment?

A,We have hundreds of patents and passed the IS9001:2015 quality management system certification.

B,The Technical Review Committee,reasonably determines and divides the stages of design, production, installation and commissioning, and formulates detailed progress plans for each stage, Strengthen the quality assurance system and quality protection measures of equipment manufacturing department.

C,We manning quality inspectors specially to control the processing quality of product strictly.

How to install equipment after purchasing your equipment?

A,We will provide installation information and installation videos

B,Our engineers will guide the installation and run the equipment.

C,After the debugging, will provide complete training and track customer device usage.

How is your company's after-sales service done?

A,Provide the list of consumables to assist customers in establishing a

comprehensive equipment maintenance system.

comprehensive equipment maintenance system.

B,After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

C,If customer has a device failure in the process of using the device,our company will operate the device remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems. D,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

Hot Searches