- Product Details

- {{item.text}}

Quick Details

-

Feather Material:

-

Flex Feather

-

Place of Origin:

-

Anhui, China

-

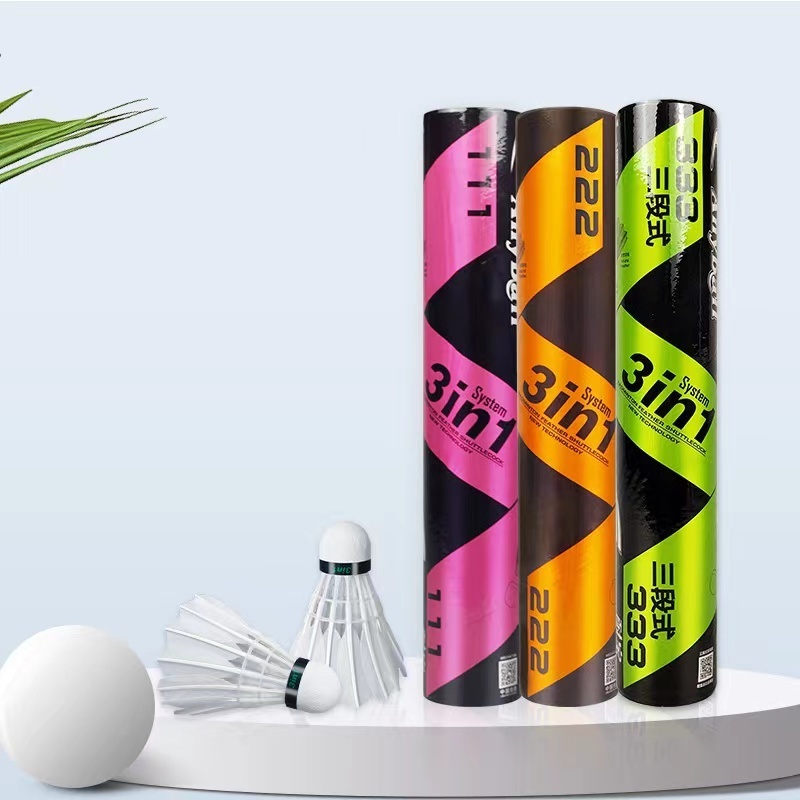

Brand Name:

-

Anyball

-

Model Number:

-

222

-

Weight (g):

-

5

-

Product Name:

-

Badminton shuttlecock wholesale

-

Color:

-

Natural White

-

Feature:

-

Stable, durable

-

OEM:

-

acceptable

-

Suitable for:

-

Amateur Training

-

Key words:

-

Cheap shuttlecock

-

Design:

-

3 in 1

-

Packing:

-

12pieces/barrel

-

Speed:

-

74-75-76-77-78

Quick Details

-

Classification:

-

Goose Feather Ball

-

Package:

-

12, 6

-

Head Material:

-

PU Cork

-

Feather Material:

-

Flex Feather

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Anyball

-

Model Number:

-

222

-

Weight (g):

-

5

-

Product Name:

-

Badminton shuttlecock wholesale

-

Color:

-

Natural White

-

Feature:

-

Stable, durable

-

OEM:

-

acceptable

-

Suitable for:

-

Amateur Training

-

Key words:

-

Cheap shuttlecock

-

Design:

-

3 in 1

-

Packing:

-

12pieces/barrel

-

Speed:

-

74-75-76-77-78

Product Description

|

Product Name

|

Badminton shuttlecock

|

|

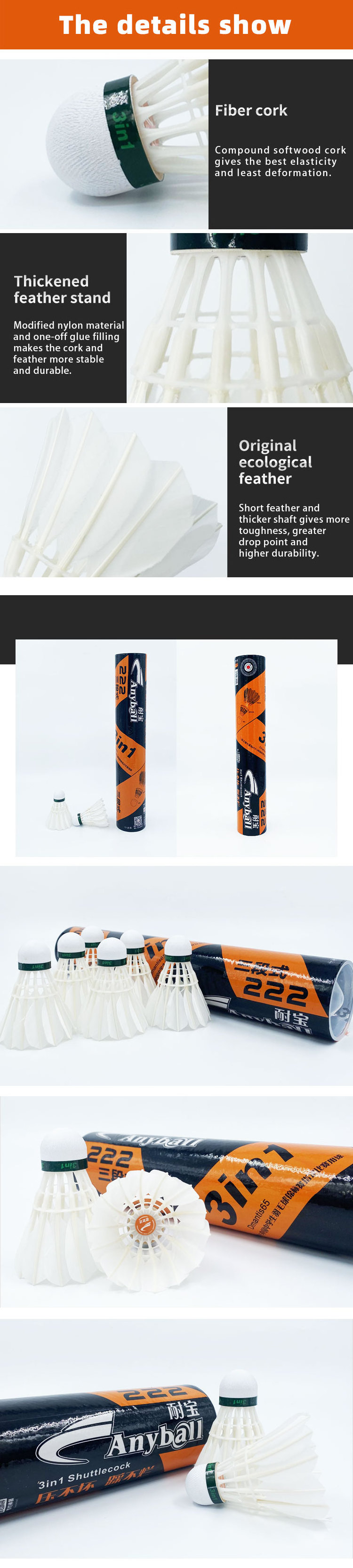

Head

|

PU Cork

|

|

Material

|

Flex Feather

|

|

Color

|

Natural white

|

|

Feature

|

Stable, durable

|

|

OEM

|

Available

|

|

Design

|

3 in 1

|

|

Manufacturer /Factory

|

Yes

|

|

Model

|

222

|

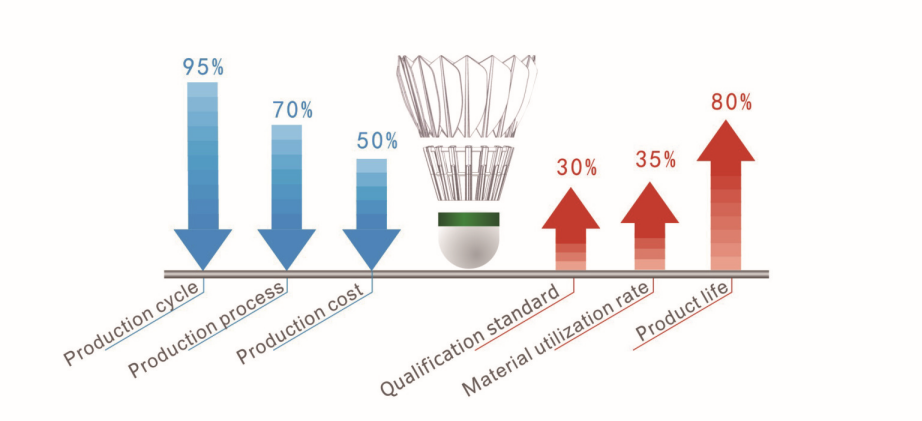

Our Advantages

The innovation of 3in1 shuttlecock , intelligence production ,

comparing with the traditional shuttlecock

, the advantages are as below :

1. Working procedure reduced 70% ; 3in1 shuttlecock procedure reduced from more than 20 into 6, use our self-research and developed intelligence all-in -one machine , finish head punch ,add bottom gum, press feather stand , add hole gum. Insert feather and wind green tape total 6 procedure in one set of automated 3in1 shuttlecock machine.

2. Production cycle reduced 99.99% (change from 30 days into 3 minutes).

3. Cost reduced 50%.

4. Production acceptance rate improved more than 30%.

5.Feather utilization rate increased 35%.

6. Production life extend 80%.

1. Working procedure reduced 70% ; 3in1 shuttlecock procedure reduced from more than 20 into 6, use our self-research and developed intelligence all-in -one machine , finish head punch ,add bottom gum, press feather stand , add hole gum. Insert feather and wind green tape total 6 procedure in one set of automated 3in1 shuttlecock machine.

2. Production cycle reduced 99.99% (change from 30 days into 3 minutes).

3. Cost reduced 50%.

4. Production acceptance rate improved more than 30%.

5.Feather utilization rate increased 35%.

6. Production life extend 80%.

Hot Searches