- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KITECH

-

Application:

-

PP PE Bottle Washing Line, Plastic Recycling Washing Line

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

25*5*4.5

-

Power (kW):

-

150-350

-

Weight (T):

-

15000

-

Raw material:

-

Waste PE PP PET Bottle

-

Automatic:

-

full automatic

-

Process:

-

Crushing / Washing/ Drying / Recycling

-

Final product:

-

Clean Plastic Scraps

-

Capacity:

-

300-2000 KG/H

-

Motor brand:

-

WEG / SIEMENS

-

Usage:

-

Recycle Waste Plastic

-

Certification:

-

CE ISO

-

Product line:

-

Plastic Film Bags Recycling Washing Line

Quick Details

-

Machine Type:

-

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KITECH

-

Application:

-

PP PE Bottle Washing Line, Plastic Recycling Washing Line

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

25*5*4.5

-

Power (kW):

-

150-350

-

Weight (T):

-

15000

-

Raw material:

-

Waste PE PP PET Bottle

-

Automatic:

-

full automatic

-

Process:

-

Crushing / Washing/ Drying / Recycling

-

Final product:

-

Clean Plastic Scraps

-

Capacity:

-

300-2000 KG/H

-

Motor brand:

-

WEG / SIEMENS

-

Usage:

-

Recycle Waste Plastic

-

Certification:

-

CE ISO

-

Product line:

-

Plastic Film Bags Recycling Washing Line

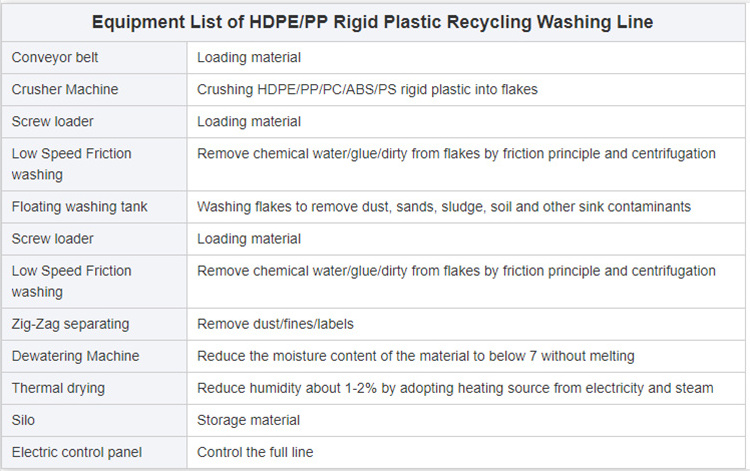

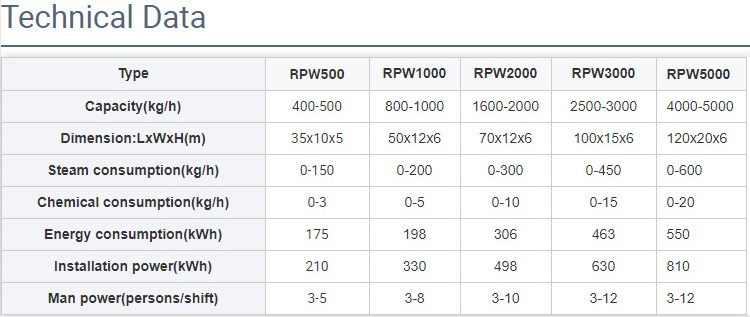

>> You can get a different module combinations design from KITECH according to your requirements and material's condition. In range of different raw materials, KITECH provides 400-5000kg/h economy and high-level production lines with different configurations.

Working principle and flow chart:

>>After getting waste plastic raw material, KITECH Technicians will study and analysis the main contaminants to provide a proper solution to remove most of the impurities by mechanical, chemical, physical and other principle. >>Main process of whole project including pretreatment of raw material → crushing → washing → drying → package → granulation.

|

Belt conveyor >>Heavy duty type, adopt gear motor; >>Side walls to avoid spilling of feeding material; |

|

Shredder >>Special designed hopper to avoid material flying out; >>4-way rotating knives with special knife holders; >>Extremely robust pedestal bearing housings; >>External mounted of bearing pedestal designs; |

|

|

Crusher >>Optimally designed blades are sharp and powerful; >>Enclosed cutting chamber to prevent materials flying out; >>Knives are externally adjustable; |

|

|

Screw Conveyor&Friction Washer

Screw Conveyor: >>Screw adopt wear resistant stainless steel; >>Triple sealing, External bearing design; Friction Washer: >>Rotor and blades adopt wear resistant steel; >>Rotor with dynamic balance treatment. >>Accuracy: ±3-5g; >>Active material washing to protect downstream units;

|

|

|

Washing Tank >>Double station discharge valve at bottom; >>All Thumb-wheel speed variable by inverter control; >>Heavy duty washing, separation of different specific densities material; |

|

|

Dewatering Machine >>Drying materials by centrifugal force ; Thermal Drying >>Further drying materials by hot air ; Storage Buffer >>Direct connect with pelletizing process; >>Large Storage capacity;

|

|

|

Electrical Cabinet >>International brand Low voltage components ; >>Double circuit safety relay; >>Intelligent and modular PLC controlling system; |

7/24 Online Service

1 - Machine running video

2 - Watch our factory online

3 - More service contact us

Successful Plastic Recycling Plant

1 - Supply a running plastic recycling line in your country ,you can see machine running directly.

Installation / Debug / Training

1 - We will arrange seasoned technician for equipment installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

After-sales Service

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.