- Product Details

- {{item.text}}

Quick Details

-

H Content (%):

-

0.009%

-

Ash Content (%):

-

0.25 <0.5%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Antuo

-

Model Number:

-

AT-CFL0165

-

Dimensions:

-

customized

-

Working Temperature:

-

Less than 200 ℃

-

Volatile:

-

N/A

-

Product name:

-

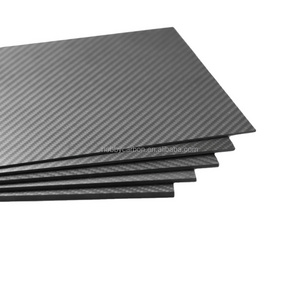

3k Carbon fiber laminates sheets plates panels

-

Material:

-

Carbon facbric + Epoxy resin

-

Technique:

-

Vacuum forming or hot press forming laminated

-

Density::

-

1.76~1.93g/cm3

-

Thickness:

-

0.2-50mm

-

Bending Strength:

-

>80-120Gpa

-

Tensile Strength:

-

>650Mpa

-

Stiffness:

-

>80-120Gpa

-

Features::

-

water-proof, heat-insulation,anti-static

Quick Details

-

C Content (%):

-

98%

-

S Content (%):

-

0.005%

-

N Content (%):

-

0.3-0.6%

-

H Content (%):

-

0.009%

-

Ash Content (%):

-

0.25 <0.5%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Antuo

-

Model Number:

-

AT-CFL0165

-

Dimensions:

-

customized

-

Working Temperature:

-

Less than 200 ℃

-

Volatile:

-

N/A

-

Product name:

-

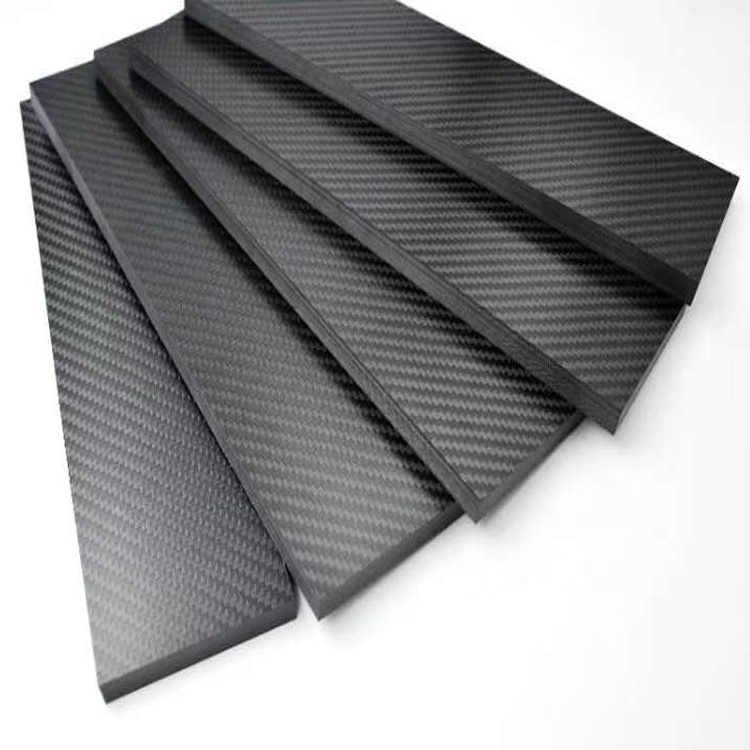

3k Carbon fiber laminates sheets plates panels

-

Material:

-

Carbon facbric + Epoxy resin

-

Technique:

-

Vacuum forming or hot press forming laminated

-

Density::

-

1.76~1.93g/cm3

-

Thickness:

-

0.2-50mm

-

Bending Strength:

-

>80-120Gpa

-

Tensile Strength:

-

>650Mpa

-

Stiffness:

-

>80-120Gpa

-

Features::

-

water-proof, heat-insulation,anti-static

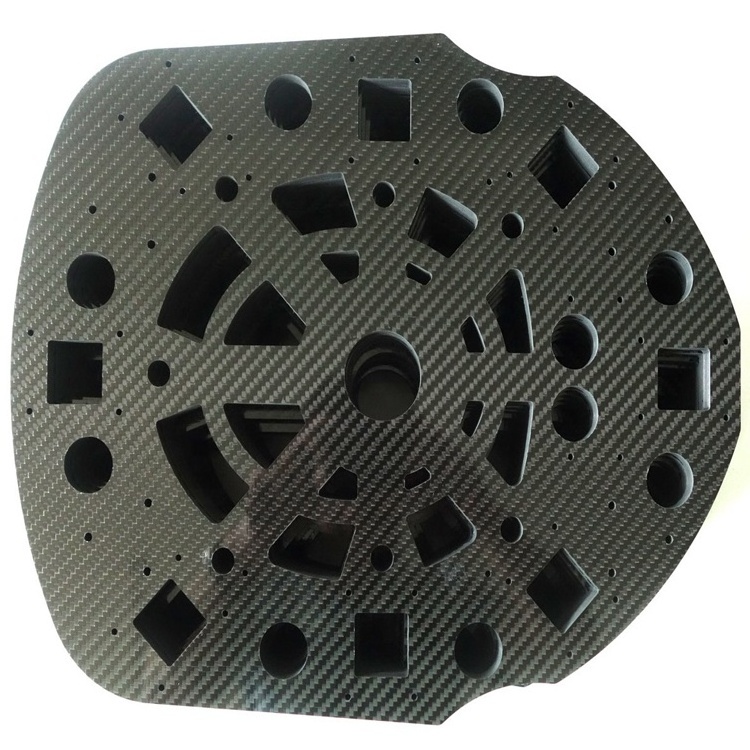

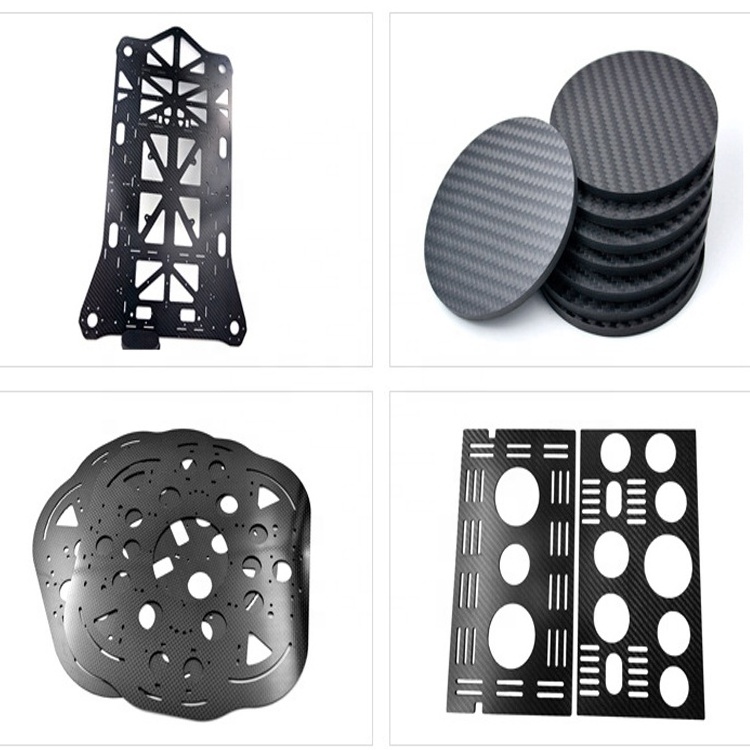

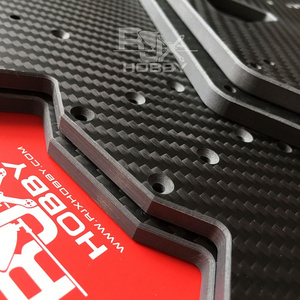

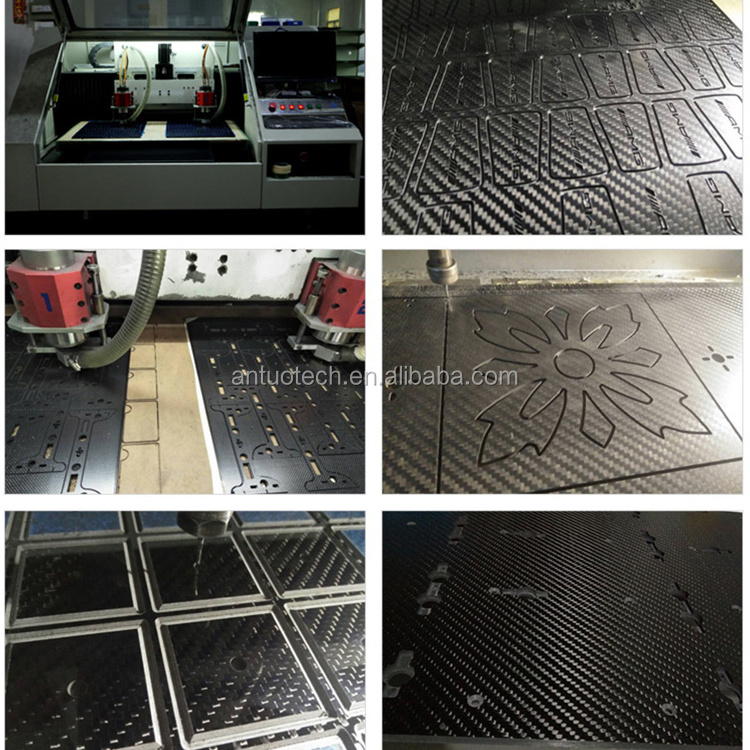

CNC 3k carbon fiber sheets for rc fpv frames, factory cnc carbon fiber sheet for rc car drone uav rc toys

The processes

of Carbon fiber laminates sheets plates panels:

a). Hand lay-up:

One using 6 layers of 100g unidirectional carbon fibre or using alternating layers of 210g 2/2 twill carbon

fibre and 300g +/- 45° biaxial carbon fibre. DSM epoxy resin is wetted into the reinforcement using a

laminating brush and then a layer of peel-ply is applied to the back of the sheet to allow excess resin to

be squeezed from the laminate and also leave a bond-able textured finish.

b). Resin infusion:

One using the same alternating layers of 200g 2/2 twill carbon fibre or 300g +/- 45° biaxial carbon fibre

that are used in the hand-layup demonstration and the other using 6 layers of 650g carbon fibre. The sheets

are infused using DMS epoxy infusion resin. The reinforcement is covered with a layer of peel-ply which is

cut over-size to create a resin break before a layer of infusion mesh is positioned directly over the

reinforcement. Resin infusion spiral and resin infusion connectors are put in place before vacuum bagging

tape and AT160 vacuum bagging film are used to complete the vacuum bagging stack. Vacuum is supplied by our

compact composites vacuum pump with a resin infusion catch-pot in place to eliminate the risk of resin being

drawn into the vacuum pump.

c). Oven-cured prepreg layup:

One laminate sample is prepared using a layer of our old prepreg out-of-autoclave surfacing prepreg top and

bottom with three layers of our old 430g prepreg (two of them cut on the 45° bias) making up the thickness.

These pre-pregs have been superceeded by our carbon fibre pre-pregs.

The layers of prepreg are consolidated using a plastic finned laminating roller before being covered in a

layer of AT110 unperforated FEP release film. A layer of breather cloth is positioned over the laminate and

into some clear space to the side of the sheet onto which a through-bag connector is positioned (our

connector is fitted with quick release vacuum couplings). The sheet is envelope bagged using AT160 vacuum

bagging film and sealed with vacuum bag sealant tape. The vacuum bagged prepreg sample is then loaded into

our soon-to-be-release AT101 curing oven to cure under full vacuum for several hours.

Specification:

Materaisl:

High modulus 3k prepreg Carbon facbric + Epoxy resin;

Density:

1.76~1.93g/cm3

Stiffness:

>80-120Gpa

Bending Strength:

>80-120Gpa

Tensile Strength:

>650Mpa

Operating Temperature:

-40F to 248F

Characteristic:

| Name | High modulus 3k Carbon fiber laminates sheets plates panels |

| Material | High modulus carbon fiber,100% carbon fiber or hybrid carbon fiber, 100% fiberglass can be provided as well |

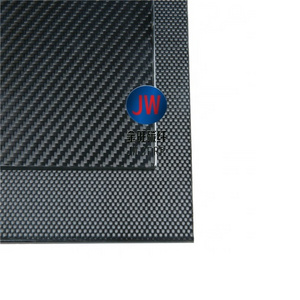

| Finish | Glossy or matte, |

| Surface | With 1k/3k/6k/12k weaving pattern |

| Tolerance | +/-0.05mm for diameter, +/-0.5mm for length |

| Technical | Laminated |

| Advantage | High strength, Light weight; |

| Tight tolerances; | |

| Anti-corrosion; | |

| Low Coefficient of thermal expansion; | |

| Customized according to your load requests; | |

| Print simple logo free for you; | |

| CNC cutting service; | |

| Accessories available; | |

| Durable and nice luxury surface | |

| UV resistance; | |

| Non-magnetic electromagnetic |

Applications:

1. Automobiles, body, parts, inside decoration etc;

2. Bike Motorbicycle, body and parts;

3. Aerospace and navigation, plane, barge, freighter, boat, ship, vessel;

4. Sports and entertainment, golf, ski pole, hockey pole, badminton pole;

5. Hunting bow and arrows archery stabilizer tennis pole, snooker pole, trekking pole ski pole;

6. Billiards cues protecting equipment etc;

7. RC hobby, UAV Drone, Copter, FPV frame parts, Tools, model;

8. Construction and Bridge reinforcement and strengthening;

9. Energy, wind turbine blades, oil driller etc;

10. Telescopic tubes/poles;

11. Music equipment, Camera support tripod pole;

12. Mobile or Jewelry electronic production decoration;

13. Medical X-ray machine Carbon devices,toys,telescopic tube;

14. Industrial mechanical parts sports products parts;

The common size chart:

|

Thickness (mm) |

Width(mm) * Length(mm) | |||||||

| 0.5 | 200*300 | 245*315 | 400*500 | 500*500 | 500*600 | 700*700 | 600*1000 | 1000*1200 |

| 0.8 | ||||||||

| 1 | ||||||||

| 1.2 | ||||||||

| 1.5 | ||||||||

| 2 | ||||||||

| 2.5 | ||||||||

| 3 | ||||||||

| 3.5 | ||||||||

| 4 | ||||||||

| 5 | ||||||||

| 6 | ||||||||

| 8 | ||||||||

| 10 | ||||||||

| 12 | ||||||||

Weave:

Plain & Twill

Surface:

Glossy & Matte

Color:

Black, red, blue, silver, yellow, etc..

Any shapes can available by CNC processing as your requirement :-)

Advantages of our carbon fiber sheets:

With more than 10 years’ experiences, we are very professional in making carbon fiber sheets. We use Toray carbon fiber as raw material. As you known, toray carbon fiber is the best around the world. We can also make tube according to your requests. So that we can make sure the sheets can work well for your application. Also, our sheets have tight tolerances. Tolerances are important but not all manufacturers can supply the carbon fiber sheets with the tight tolerances. So, it's better to let us know your specifications of your sheets, then we you can get your customized carbon fiber sheets soon!