- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shunfu

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

Product customization

-

Weight:

-

3000 kg

-

machine name:

-

toilet tissue paper manufacturing machinery machines for paper

-

Raw material:

-

waste paper,virgin pulp board etc.

-

Capacity:

-

1-10 ton/day(can be customized)

-

Out paper:

-

jumbo roll tissue paper

-

Final paper product:

-

small roll toilet,napkin paper ,facial tissue paper

-

Output paper:

-

toilet paper, toilet paper, napkin

-

Paper weight:

-

17-30 gsm

-

Certification:

-

ISO9001

-

After sale service:

-

install machine+train worker

-

Pre sales service:

-

Cost accounting, production line drawing design

Quick Details

-

Production Capacity:

-

300 m/min

-

Product Type:

-

toilet paper making machine

-

Processing Type:

-

production of toilet paper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shunfu

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

Product customization

-

Weight:

-

3000 kg

-

machine name:

-

toilet tissue paper manufacturing machinery machines for paper

-

Raw material:

-

waste paper,virgin pulp board etc.

-

Capacity:

-

1-10 ton/day(can be customized)

-

Out paper:

-

jumbo roll tissue paper

-

Final paper product:

-

small roll toilet,napkin paper ,facial tissue paper

-

Output paper:

-

toilet paper, toilet paper, napkin

-

Paper weight:

-

17-30 gsm

-

Certification:

-

ISO9001

-

After sale service:

-

install machine+train worker

-

Pre sales service:

-

Cost accounting, production line drawing design

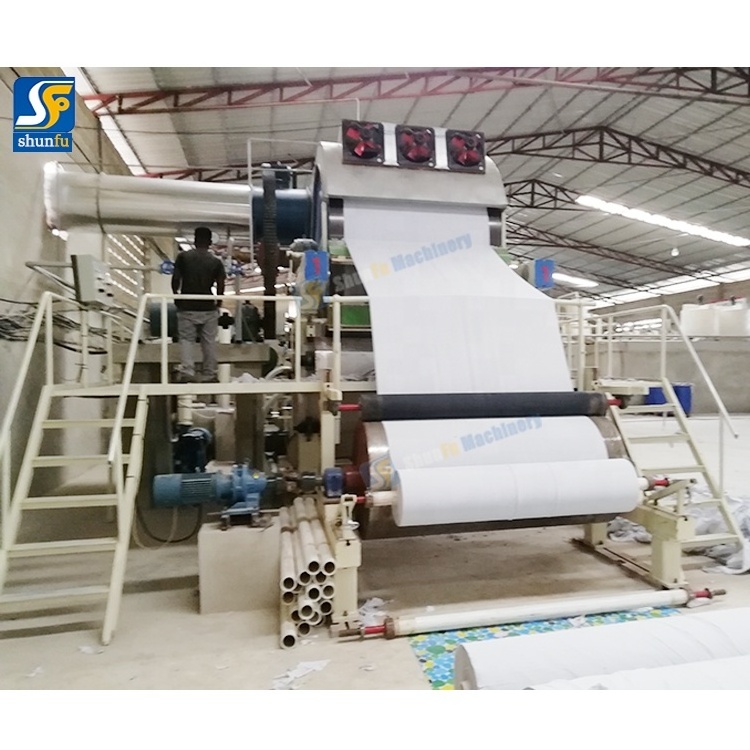

Chinese equipment toilet tissue paper manufacturing machinery machines for paper

TO ALL DEAR CUSTOMERS:

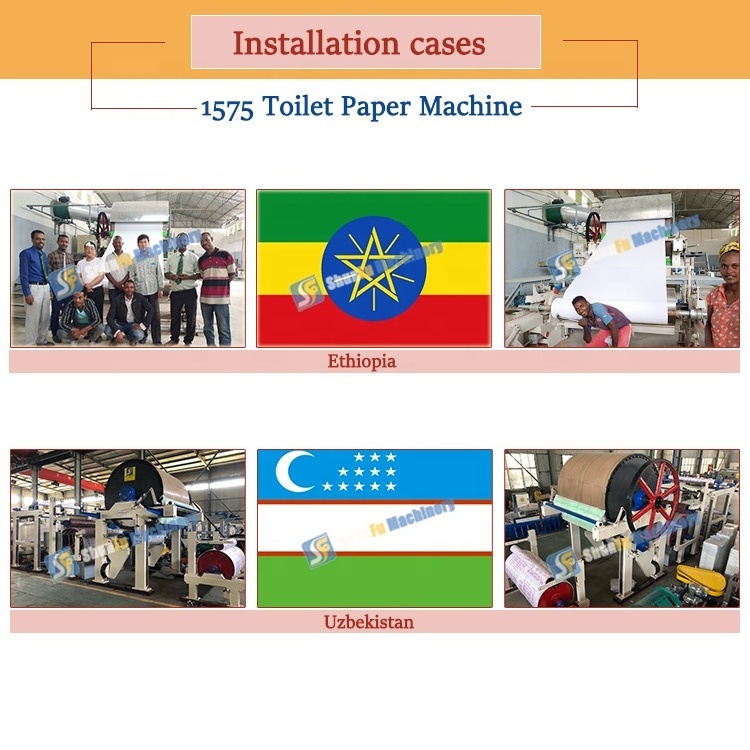

We have been done this paper making machine line for 34 years,we sold toilet tissue paper machine lines to 60 countries in the world.

Due to machines business,we know many goods friends from all over the world,due to machine business,our company are more closed to the world.Thanks for the support of old and new customer,thanks for the great era.

Meanwhile welcome more friends to visit our factory.

PRODUCT INTRODUCTION

The toilet tissue paper making machine line is the machine production line makes the raw materials into final paper.The raw materials can be waste paper,virgin/wood pulp board,hemp,bamboo and so on.The final paper can be jumbo roll tissue paper ,small roll toilet paper,napkin paper ,facial tissue paper etc.The process flows is paper pulp making,paper making,paper processing three big parts.

PRODUCT PARAMETER

| NO. | Items | Detailed Description |

| 1. |

Machine Model |

SF-787 /1092/1575/1880/2100/2200/2600/3200/3600etc.(can be customized) |

| 2. |

Out paper |

Jumbo roll toilet tissue paper |

| 3. |

Jumbo roll width |

900mm-3600mm (can be customized) |

| 2. |

Final paper product |

small roll toilet paper,napkin paper,facial tissue ,Kitchen paper,etc. |

| 3. | Raw materials | Waste paper,virgin pulp/wood pulp etc.(can be customized) |

| 4. | Paper weight | 15-30g/m2 |

| 5. | Machine capacity | 1-50 ton per day( can be customized ) |

| 6. | Work speed | 20-500m/min(can be customized ) |

PRODUCT PRODUCTION FLOWS

PART 1. PULPING

<<<This step is making raw material into paper pulp >>>

The raw materials quality will affect paper quality mainly.The better the quality of the raw material, the better the quality of the finished paper.In common raw materials are wood/virgin pulp,waste paper etc.Also can use wheat straw,rice straw,hemp,bamboo and so on.

The pulp equipment machine will be equipped according to the raw materials kinds and machine line capacity.

Different raw material will use different pulp machine.

The bigger the output of the machine production line, the greater production of pulp making equipment.

PART 2. FORMING

<<<In this step,the prepared pulp is dewatered through cylinder mould to form a wet paper sheet >>>

The forming type can divide 2 types.One type is cylinder mould type,it is will be used in medium small capacity machine line (The following photo is cylinder mould type). The other type is fourdrinier type,it is will be used in big capacity machine line.

PART 3. DRYING

<<<In this step,the wet paper sheet will be dried by dryer cylinder >>>

The dryed cylinder is the main part of toilet paper machine line.It is dried for wet paper with hot steam which provided by boiler.

The boiler has different fuel boiler,you can choose one type boiler depends on your country condition.

PART 4. REELNG

<<<Reeling is the last step of jumbo roll paper making >>>

The width of reeling paper roller & the dryer cylinder & the cylinder mould are the same one.In this step,the jumbo roll tissue paper product is finished.

JUMBO ROLL TISSUE PAPER

OTHER PROCESSING MACHINES

If you want small roll toilet paper ,napkin paper,facial tissue,kitchen paper towel ,need to use paper processing machine to produce.