The dynamic balancing machine is a hard-supported balancing machine. The swing frame is very rigid. To

Detect the unbalance of various rotating rotors, such as pulverizer rotors, industrial washing machine dryer rotors, turbine rotors, guide wheels, etc. Special designed brackets can effectively transmit mechanical force;The durable and reliable sensor possesses high sensitivity; The permanent calibration brings high accuracy;Driven by universal coupling, transmit the power steadily.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZME

-

Model Number:

-

ZME-9702A, ZME-9702A

-

Max Mass of Workpiece(kg):

-

1000

-

Max Diameter of Workpiece:

-

1000mm~1500mm

-

Diameter Scope of Driving Belt (mm):

-

max700

-

Length of Bed (mm):

-

2000

-

Balance speed (r/min):

-

Frequency conversion stepless speed regulation

-

Drive shaft torque(N.m):

-

120

-

Motor Power (KW):

-

1.5~3 (Inverter motor)

-

The smallest achievable:

-

emar≤0.5

-

Unbalance reduction rate (%):

-

URR≥95%

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZME

-

Model Number:

-

ZME-9702A, ZME-9702A

-

Max Mass of Workpiece(kg):

-

1000

-

Max Diameter of Workpiece:

-

1000mm~1500mm

-

Diameter Scope of Driving Belt (mm):

-

max700

-

Length of Bed (mm):

-

2000

-

Balance speed (r/min):

-

Frequency conversion stepless speed regulation

-

Drive shaft torque(N.m):

-

120

-

Motor Power (KW):

-

1.5~3 (Inverter motor)

-

The smallest achievable:

-

emar≤0.5

-

Unbalance reduction rate (%):

-

URR≥95%

Product Description

Universal Joint Drive Balancing Machine

Introduction

1.Applicable to rotors which can't be driven by belt or need large power.

1.Applicable to rotors which can't be driven by belt or need large power.

2.Advanced electrical measuring system and friendly man-machine interface.

3.It's applicable for blower, large-sized motor, pump, centrifuge, rubber roller, drying cylinder, internal-combustion

engine etc.

3.It's applicable for blower, large-sized motor, pump, centrifuge, rubber roller, drying cylinder, internal-combustion

engine etc.

The measurement result of the dynamic balancing machine is used to correct the unbalance, so that the vibration generated when the rotor rotates or acts on the vibration on the bearing is reduced to the allowable range to achieve the purpose of reducing vibration, improving performance and improving product quality.

Specification

|

Model Number

|

ZME-9702A

|

|

Max Mass of Workpiece(kg)

|

1000

|

|

Max Diameter of Workpiece

|

1000mm~1500mm

|

|

Diameter Scope of Driving Belt (mm)

|

max700

|

|

Length of Bed (mm)

|

2000

|

|

Balance speed (r/min)

|

Frequency conversion stepless speed regulation

|

|

Drive shaft torque(N.m)

|

120

|

|

Motor Power (KW)

|

1.5~3 (Inverter motor)

|

|

The smallest achievable

|

emar≤0.5

|

|

Unbalance reduction rate (%)

|

URR≥95%

|

Purpose:

An unbalanced rotor generates a pressure on its supporting structure and the rotor itself during its rotation, and causes vibration. Therefore, the dynamic balance of the rotor is very necessary. The balancing machine is to check the dynamic balance of the rotor in the rotating state.

It is mainly a hard-bearing balancing machine that combines high-precision mechanical parts and advanced electrical

parts into one. This series of products is one of the universal universal joint drive balancing machines developed, designed and manufactured by our company based on the core technology at home and abroad.

The function of dynamic balance is:

1. Improve the quality of the rotor and its components

2. Reduce noise

3. Reduce vibration

4. Improve the trial life of supporting parts (bearings)

5. Reduce user discomfort

6. Reduce the power consumption of the product

It uses universal joints to connect the main shaft of the balancing machine with the rotor. The characteristic of coupling drag is that it is suitable for rotors with irregular appearance, can transmit larger torque, and is suitable for dragging rotors with large wind resistance such as fans. The disadvantage of coupling drag is that the unbalance of the coupling itself will affect The rotor has an impact (so the coupling must be balanced before use), and interference will also be introduced to affect the accuracy of the balance. In addition, a large number of connecting disks must be made to adapt to different types of rotors.

1. Improve the quality of the rotor and its components

2. Reduce noise

3. Reduce vibration

4. Improve the trial life of supporting parts (bearings)

5. Reduce user discomfort

6. Reduce the power consumption of the product

It uses universal joints to connect the main shaft of the balancing machine with the rotor. The characteristic of coupling drag is that it is suitable for rotors with irregular appearance, can transmit larger torque, and is suitable for dragging rotors with large wind resistance such as fans. The disadvantage of coupling drag is that the unbalance of the coupling itself will affect The rotor has an impact (so the coupling must be balanced before use), and interference will also be introduced to affect the accuracy of the balance. In addition, a large number of connecting disks must be made to adapt to different types of rotors.

It is mainly a hard-bearing balancing machine that combines high-precision mechanical parts and advanced electrical

parts into one. This series of products is one of the universal universal joint drive balancing machines developed, designed and manufactured by our company based on the core technology at home and abroad.

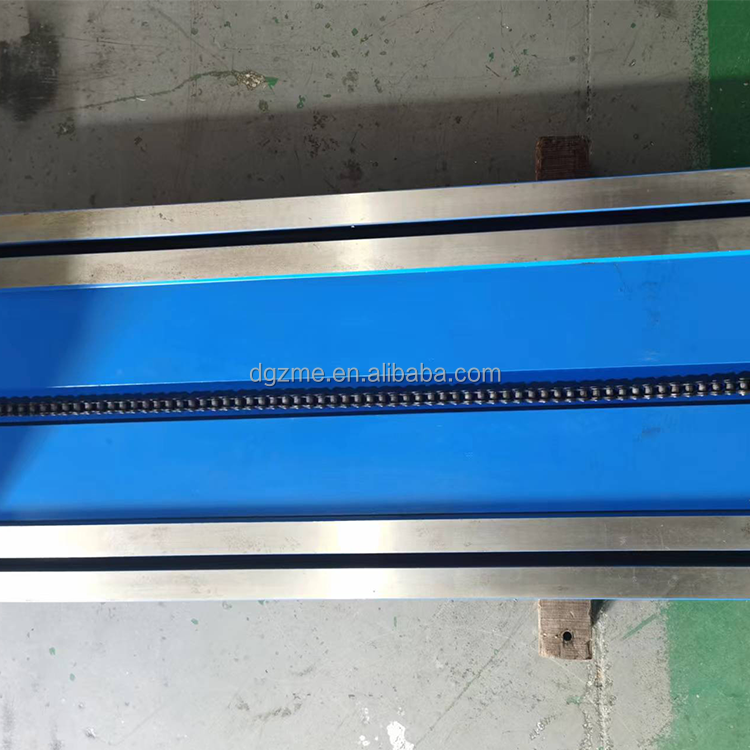

Details Images

Hot Searches