- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingxin

-

Dimension(L*W*H):

-

1150x1275x1240mm

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

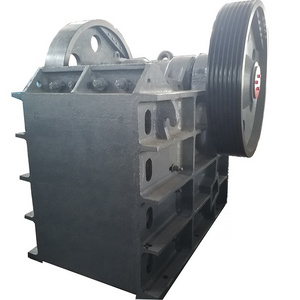

Stone PE/PEC Jaw Crusher

-

Product name:

-

Widely-used Mining Equipment

-

The Machines classification:

-

Building Stone Production Line

-

Color:

-

Red, Yellow, Orange

-

Keyword:

-

Stone Jaw Crusher

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Paid

-

Max feeding size:

-

1200mm

-

Brand:

-

Mingxin

Quick Details

-

Application:

-

Mining,construction,ore,stone

-

Capacity(t/h):

-

5-1100 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingxin

-

Dimension(L*W*H):

-

1150x1275x1240mm

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Stone PE/PEC Jaw Crusher

-

Product name:

-

Widely-used Mining Equipment

-

The Machines classification:

-

Building Stone Production Line

-

Color:

-

Red, Yellow, Orange

-

Keyword:

-

Stone Jaw Crusher

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Paid

-

Max feeding size:

-

1200mm

-

Brand:

-

Mingxin

Portable PE 150x250 diesel engine jaw crusher machine gold mining equipment

Features :

1. Low noise, less dust.

2. The high crushing ratio, uniform product granularity.

3. Simple structure, reliable work, low operating costs.

4. The lubrication system is safe and reliable, easy to replace parts, and the equipment maintenance is simple.

5. Crushing cavity is deep and there is no dead zone, so as to improve the feed capacity and output.

6. Energy-saving equipment: the single can save 15% ~ 30% energy, and the system can save double energy at least.

7. The discharge gate has wide adjustable range and can meet the requirements of different users.

Machine parameters :

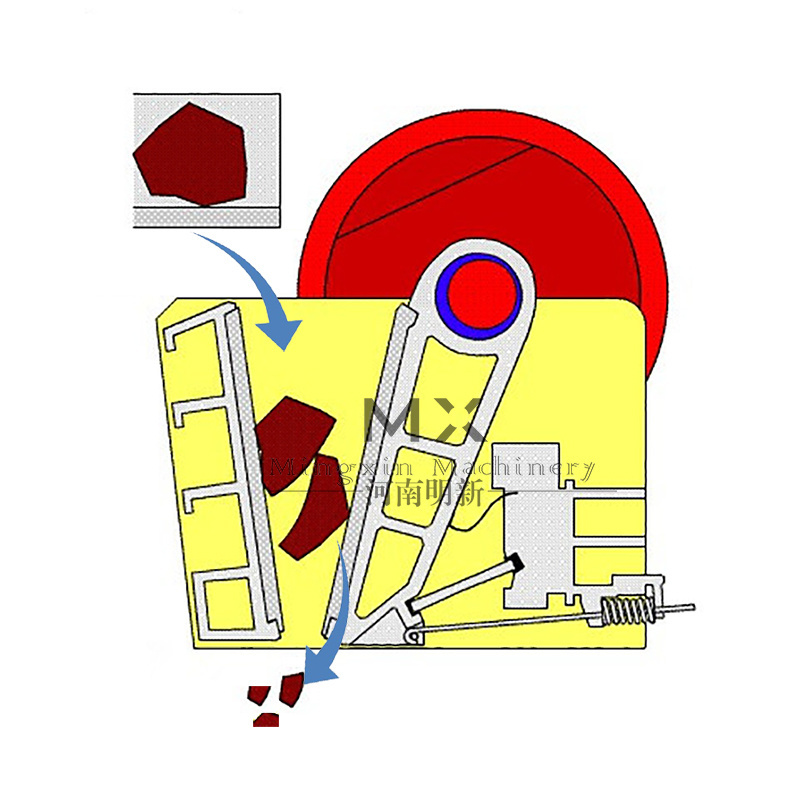

Working Principle

When the jaw crusher is working, the movable jaw plate makes periodic alternating motion to the fixed jaw plate, thus they are sep a rated and close to each other in turn. When they are close to each other, the material between two jaw plates is crushed by being extruded, bent and split. When they are separated, the material crushed is discharged from discharge gate by gravity.

In the process of breaking the huge stones into small stones, the first crusher is usually the "main" crusher. The oldest and the most solid crusher is the

jaw crusher.

When the jaw crusher is fed, the material is poured from the top entrance into the crushing chamber containing the jaw teeth, and the jaw teeth are used to make the material to the wall of the chamber with great power, which is broken into smaller stones.

Eccentric shaft, through the body frame, supports the jaw movement. Eccentric motion is usually caused by a flywheel fixed at both ends of the shaft. Flywheel and eccentric support bearings are often adapt spherical roller bearings, which must

be subjected to a huge impact load, abrasive sewage and high temperature.

Crushing ratio of stone crusher rock jaw crusher

The crushing ratio is an important index to evaluate the jaw crusher. The crushing ratio of jaw crusher is the ratio of raw material granularity and the product precision after crushing. It indicates the degree of reduction of raw material after crushing. When the ore is broken, the granularity becomes smaller, and the ratio of the granularity of the ore before crushing and that of the ore after crushing is known as the crushing ratio, which indicates the decreased numerical value of the granularity after the ore crushing. The crushing ratio can be calculated as follows:

1. Calculate by the maximum granularity of the ore before crushing and that of the ore after crushing, which is used most often in China's concentrator design, because the jaw crusher feeding port width is designed according to the maximum granularity.

2. The ratio of the effective width and the width of the discharge port of the jaw crusher.

the size of the discharge in some jaw crusher is not determined by the size of the discharge port.

3. Calculate by the average particle size before and after the ore crushing, which is also known as the average crushing ratio

Raw Materials

Final Products

Packing of Jaw Crusher Machine: Container/Wooden case

Delivery of Jaw Crusher Machine: within 20 working days after receiving your deposit

Q: How about the quality of your products?

A:We put the quality in the first place based on the honesty. Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before the delivery. You can also use Trade Assurance by Alibaba for product quality protection, punctual shipment protection and payment protection.

Q: When do you deliver the goods?

A:We usually deliver the goods within 10 days depending on detailed product. We will advise the detailed delivery time according to your specific inquiry.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to solve your problems promptly and thoroughly.