- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

224-221-9

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

OEM

-

Model Number:

-

GP

-

Type:

-

Acetoxy cure

-

Name:

-

acetic silicone building sealant

-

RTV:

-

acetic cure

-

Part:

-

one part

-

Purpose:

-

lass, windows, doors, tile, ceramic, aluminium, wood, etc

-

Characteristic:

-

fast curing, excellent waterproof, weather resistent

-

Color:

-

white, clear, black, grey, and other customer-made colors

-

Volume:

-

300ml, 280ml, 260ml, 240ml etc

-

Quality:

-

equivalent to DC

-

Shelf life:

-

over 12 months

-

Delivery Time:

-

10-20 Days

Quick Details

-

CAS No.:

-

4253-34-3

-

Other Names:

-

gap filler

-

MF:

-

Mixture

-

EINECS No.:

-

224-221-9

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

OEM

-

Model Number:

-

GP

-

Type:

-

Acetoxy cure

-

Name:

-

acetic silicone building sealant

-

RTV:

-

acetic cure

-

Part:

-

one part

-

Purpose:

-

lass, windows, doors, tile, ceramic, aluminium, wood, etc

-

Characteristic:

-

fast curing, excellent waterproof, weather resistent

-

Color:

-

white, clear, black, grey, and other customer-made colors

-

Volume:

-

300ml, 280ml, 260ml, 240ml etc

-

Quality:

-

equivalent to DC

-

Shelf life:

-

over 12 months

-

Delivery Time:

-

10-20 Days

Product Description

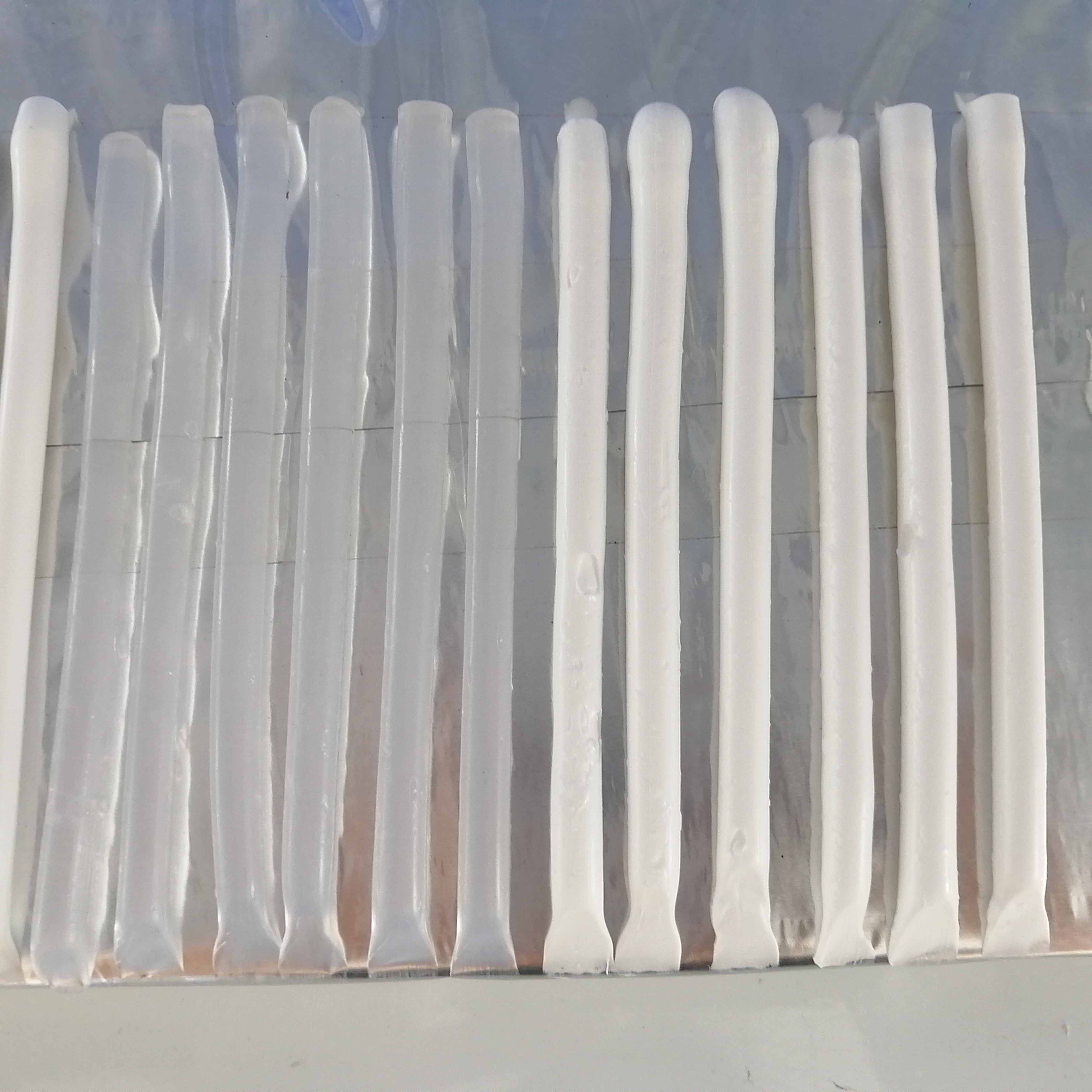

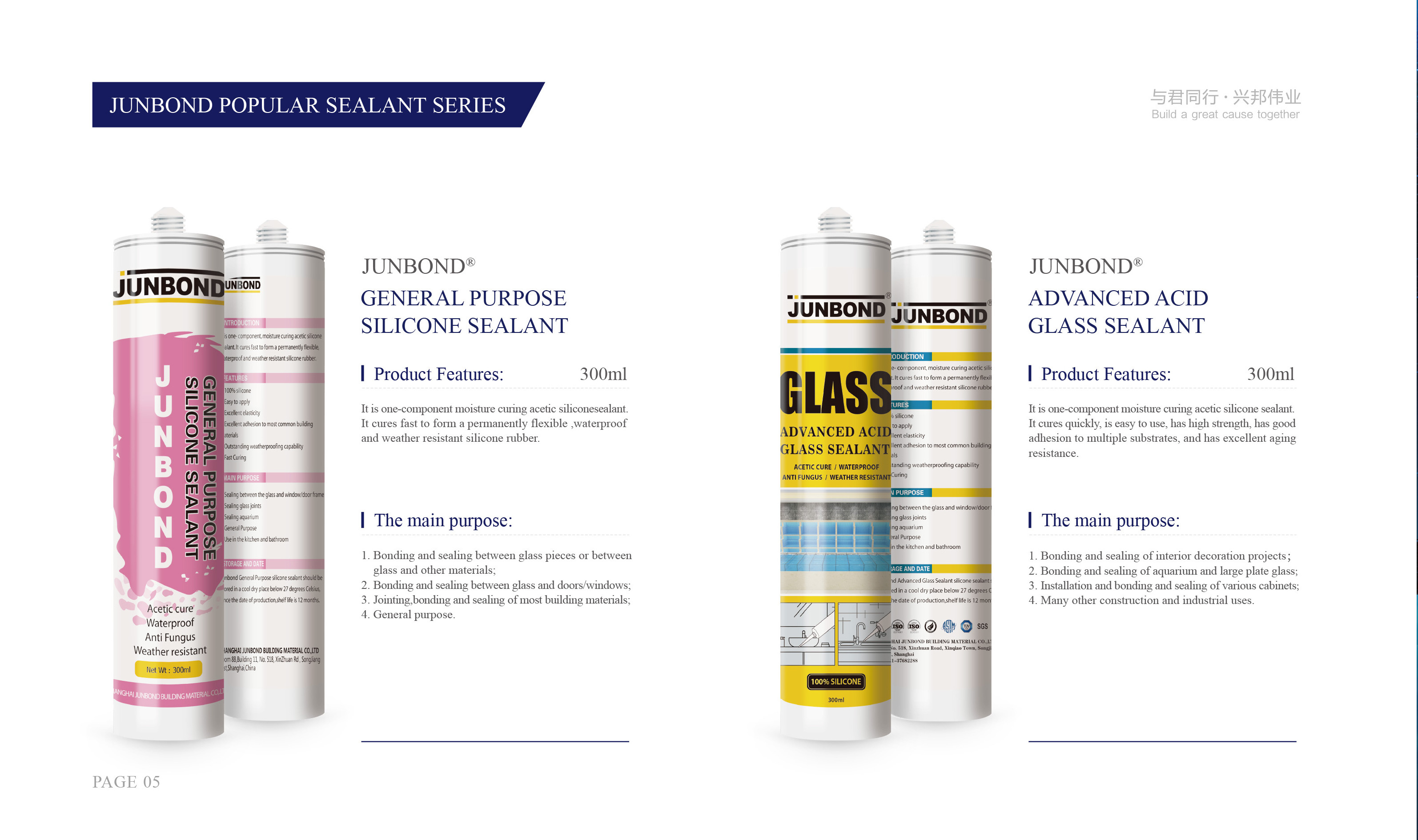

popular in Turkey barrel package rtv good quality factory price clear acetoxy GP silicone sealant

Features:

One-component room temperature curing neutral,easy to use.In the temperature range 4-40℃’s has good extrusion and thixotropy. For

most materials have good adhesive roperties.Excellent weather resistance and high temperature performance,is the ideal weather sea

Directions:

Must use a solvent such as toluene or acetone,at the interface clean and keep dry.Construction of application of sealant to

completely fill the joints to ensure that both sides of bonding.They needs to protect the side labeled tape,but not touch the tape

will be the construction surface.The plastic is not cured prior to trimming immediately in order to achieve a beautiful look.

Cautions:

1.Not available in all surface leaking grease,plasticize or solvents.

2.Difficult for enclose spaces or in direct contact with the surface of the food or drinking water.

3.The substrate surface temperature is below 4℃or over 40℃ not construction.Should not adhered copper or copper alloy material.

One-component room temperature curing neutral,easy to use.In the temperature range 4-40℃’s has good extrusion and thixotropy. For

most materials have good adhesive roperties.Excellent weather resistance and high temperature performance,is the ideal weather sea

Directions:

Must use a solvent such as toluene or acetone,at the interface clean and keep dry.Construction of application of sealant to

completely fill the joints to ensure that both sides of bonding.They needs to protect the side labeled tape,but not touch the tape

will be the construction surface.The plastic is not cured prior to trimming immediately in order to achieve a beautiful look.

Cautions:

1.Not available in all surface leaking grease,plasticize or solvents.

2.Difficult for enclose spaces or in direct contact with the surface of the food or drinking water.

3.The substrate surface temperature is below 4℃or over 40℃ not construction.Should not adhered copper or copper alloy material.

|

Test Item

|

Unit

|

Actual results

|

|

Appearance

|

|

Smooth, no air bubbles, no lumps

|

|

Tack free time(at what % humidity)

|

min

|

5

|

|

Slump

|

mm

|

0

|

|

Extrusion

|

ml/min

|

1483

|

|

Shore A hardness /72h

|

|

27

|

|

Weight loss

|

|

4%

|

|

Cracking

|

|

No

|

|

Chalking

|

|

No

|

|

Tensile adhesion

|

Mpa

|

0.6

|

|

Elongation at break

|

%

|

316

|

|

Specific gravity

|

g/cm3

|

1

|

|

Completely dry

|

hours

|

16

|

|

Temperature Resistence

|

°C

|

-50℃~150℃

|

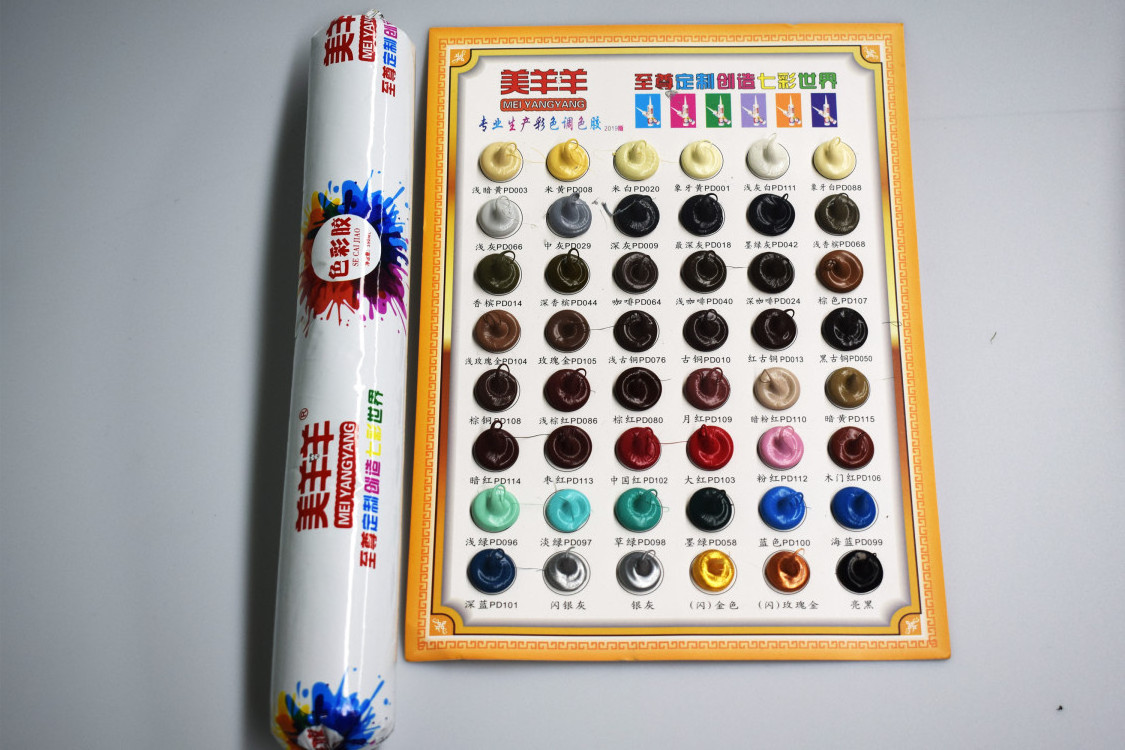

Colors:We can send you color chat,or tell us the number of the

Ral color card or Panton color card

Factory show

Since Its Establishment, Junbom Group Has Been Focusing On The R&D, Production And Sales Of One-Component Silicone sealant,Two-Component Silicone sealant, Polyurethane Foam, Beauty Seam Agent, And Environmentally Friendly High-Elastic Rubber. Six Production Bases Have Been Established (Foshan Jiaolang New Material Technology Co., Ltd., Foshan Pengda New Material Technology Co., Ltd., Hubei Junbond New Material Technology Co., Ltd., Yichang Zhongzhi Environmental Protection Technology Co., Ltd., Anhui Weilang Chemical Technology Co., Ltd. , Guangdong Junbond New Material Technology Co., Ltd.), With A Total Production Area Of More Than 100,000 Square Meters, More Than 1,200 Employees, And Total Annual Sales Of Up To 1.5 Billion.

Since The Birth Of The Group In 2016, It Has Entered A Period Of Rapid Development, Creating The "Junbom Speed" In The Industry. In The Future, Junbom Will Make Unremitting Efforts, Continue To Explore, And Create A New Junbom Model In The Industry.

A Perfect Production System Has Created A First-Class Enterprise, And Has Been Committed To Providing Customers With First-Class Quality Products. Now We Have More Than 30 Advanced Automatic Production Lines For Silicone Rubber, 8 Production Lines For Styrofoam, 3 Automatic Production Lines For Beautiful Seam Agent, And 2 Automatic Production Lines For Environmentally Friendly High-Elastic Rubber. All Products Use High-Quality And High-Standard Raw Materials. Scientific Control And Effective Supervision Of Each Process Link Of The Company Ensure That Every Product Produced Meets Industry Standards.

The Overall Situation Will Never Allow Us To Relax, Pursue The Common Development Vision Of "Going With The Junbom And Prosper The State", Build The "Junbom Platform", And Truly Realize The Win-Win Situation Of Upstream Partners, Outstanding Employees Of The Group, And High-Quality Downstream Customers.

Since The Birth Of The Group In 2016, It Has Entered A Period Of Rapid Development, Creating The "Junbom Speed" In The Industry. In The Future, Junbom Will Make Unremitting Efforts, Continue To Explore, And Create A New Junbom Model In The Industry.

A Perfect Production System Has Created A First-Class Enterprise, And Has Been Committed To Providing Customers With First-Class Quality Products. Now We Have More Than 30 Advanced Automatic Production Lines For Silicone Rubber, 8 Production Lines For Styrofoam, 3 Automatic Production Lines For Beautiful Seam Agent, And 2 Automatic Production Lines For Environmentally Friendly High-Elastic Rubber. All Products Use High-Quality And High-Standard Raw Materials. Scientific Control And Effective Supervision Of Each Process Link Of The Company Ensure That Every Product Produced Meets Industry Standards.

The Overall Situation Will Never Allow Us To Relax, Pursue The Common Development Vision Of "Going With The Junbom And Prosper The State", Build The "Junbom Platform", And Truly Realize The Win-Win Situation Of Upstream Partners, Outstanding Employees Of The Group, And High-Quality Downstream Customers.

Exhibition

Certificate

Why Choose Us

FAQ

Q: What is delivery time?

A: Normally,delivery time of sample order is 2 to 3 days ,standard order is 15 days after deposit. Except for public holidays.

Q: How can you guarantee the quality?

A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

Q: How long can I get a quote?

A: The quotation can be provided not longer than 24 hours on condition that we know all detailed requirements.

Q: Can I get a sample?

A: Yes we offer free samples. Delivery cost is to be paid by clients.

Q: Can you provide OEM service?

A: Yes,we can produce under your own brandname. Logo and design need to be provided so as to make customized brandname.

A: Normally,delivery time of sample order is 2 to 3 days ,standard order is 15 days after deposit. Except for public holidays.

Q: How can you guarantee the quality?

A: We have rigorous quality test system, from raw materials to finished products, the materials must be checked and signed by QC people.

Q: How long can I get a quote?

A: The quotation can be provided not longer than 24 hours on condition that we know all detailed requirements.

Q: Can I get a sample?

A: Yes we offer free samples. Delivery cost is to be paid by clients.

Q: Can you provide OEM service?

A: Yes,we can produce under your own brandname. Logo and design need to be provided so as to make customized brandname.

Hot Searches