- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingyang

-

Dimension(L*W*H):

-

1.43*1.35*1.45m

-

Model:

-

T290

-

Capacity:

-

1--2t/h

-

Weight:

-

550kg/600kg

-

Raw Material:

-

budgust, carbon dust

-

Moisture of raw material:

-

12-15%

-

Usage:

-

make briquette

-

Product name:

-

South Africa Waste Metal Dry Coal Powder Clay Ball Pressing Machines

-

Keywords1:

-

Famous Brand Waste Ash Light Faster Briquetting Machine

-

keywords2:

-

Customize Size Shape Cast Iron Powder Ball Press Machine

-

keywords3:

-

Roll Forming Square Shaped Briquette Press Machine

Quick Details

-

Weight (KG):

-

800

-

Production Capacity:

-

100%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Dimension(L*W*H):

-

1.43*1.35*1.45m

-

Model:

-

T290

-

Capacity:

-

1--2t/h

-

Weight:

-

550kg/600kg

-

Raw Material:

-

budgust, carbon dust

-

Moisture of raw material:

-

12-15%

-

Usage:

-

make briquette

-

Product name:

-

South Africa Waste Metal Dry Coal Powder Clay Ball Pressing Machines

-

Keywords1:

-

Famous Brand Waste Ash Light Faster Briquetting Machine

-

keywords2:

-

Customize Size Shape Cast Iron Powder Ball Press Machine

-

keywords3:

-

Roll Forming Square Shaped Briquette Press Machine

Pressing Pressure Ball Machine Rice Husk Coal Briquette Roller Press Charcoal Briquetting Machine

|

Model |

Power | Capacity(h/t) | Weight(t) | Appearance Size(m) |

| T290 | 5.5kw | 1-3t/h | 500kg | 1.45*1.35*1.43 |

| 430 | 7.5kw | 8-10 t/h | 2.1t/2.5t | 2.1*1.28*1.63m |

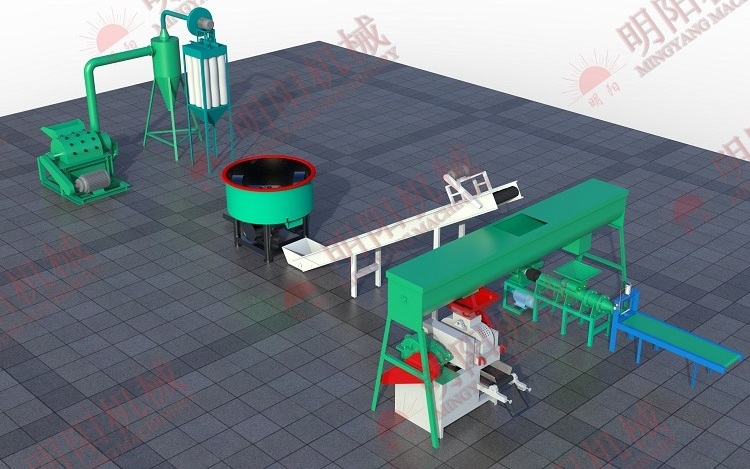

Product Details of Charcoal Coal ball Briquette Making Production Line

Coal Power Briquette Machine is widely used to making coal powder into briquettes for boiler, furnace,home heating, etc. It is also suitable for other raw materials such as gypsum, fluorspar,charcoal,coke, iron fines, chorm ore and other kinds of other powder materials.

Working Principle of Charcoal Coal ball pressure machine

The pre-pressing screw force the raw material into the middle of the roll. Then the material is compressed due to the constant reverse rotation. The pressure from small to large until the center line of the roll is "0-0". As the roll continues rotate, the pressure reaches the maximum value,and the ball briquette form shape. With the forming pressure decreases continuously until the ball briquette remove from roll

Feature of Charcoal Coal ball pressure machine

1.High pressure,strong stability, and resist wear-resisting, high production quality, stable performance, easy to operate and maintain, always has good feedback.

2.Materials made by briquette are energy saving and environmental protection, and easy to transportate.It can bring modest profit and social benefits.

3.The shape can be designed of round ball shape, oval shape, oblateness, pillow shape,elongated shape, square shape.( also can be designed according to the customer requirements.)

4.Professional powder materials briquette machine manufacturer.

5.High capacity.

Notes

of

Charcoal Coal ball pressure machine

(1)No blocks,stones and other hard objects into the machine;

(2)machining particle size should be made sure under 3mm;

(3)no heavy load starts,prohibit non-technical personnel modulation equipment;

(4)Regular maintenance, to observe whether the reducer and housing needs fuel.

Production Line

1.Crush the raw material into small pieces (diameter is about 3-5mm).

2.Dry the material by dryer machine , till the moisture is less than 12%.

3.Put the material into sawdust carbonization stove.

4.Then put the charcoal dust into the coal briquette machine.