- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

INNOVA

-

Application:

-

NSS test, ASS test, CASS test and so on

-

Falling fog amount (m/80cm/hr):

-

0.5-3.0

-

Power supply:

-

AC 1 Phase 220V 60/50Hz

-

Material:

-

PVC

-

Spray system:

-

Air acid (base) liquid

-

Heating system:

-

SUS #304 Stainless steel high-speed heater

-

Control system:

-

Push-button digital display controller+ timer+SSR+PID

-

Other componets:

-

Hydrometer, salinity meter, mist collector, glass strip

-

PH:

-

Brine PH 6.5-7.2;PH value of copper acetate 3.0-3.2

-

Certification:

-

ISO CE

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

China

-

Brand Name:

-

INNOVA

-

Application:

-

NSS test, ASS test, CASS test and so on

-

Falling fog amount (m/80cm/hr):

-

0.5-3.0

-

Power supply:

-

AC 1 Phase 220V 60/50Hz

-

Material:

-

PVC

-

Spray system:

-

Air acid (base) liquid

-

Heating system:

-

SUS #304 Stainless steel high-speed heater

-

Control system:

-

Push-button digital display controller+ timer+SSR+PID

-

Other componets:

-

Hydrometer, salinity meter, mist collector, glass strip

-

PH:

-

Brine PH 6.5-7.2;PH value of copper acetate 3.0-3.2

-

Certification:

-

ISO CE

Product Description

Specification

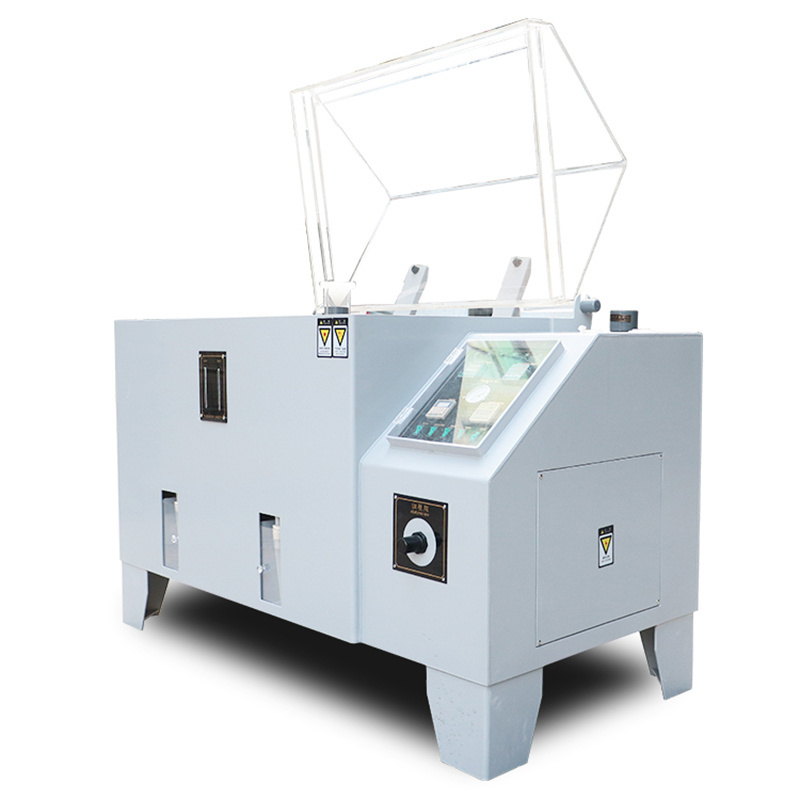

What is metal coating salt spray test chamber?

Metal coating salt spray test chamber is used to inspect salt corrosion ability of materials and protective layers through

simulating ocean climate, compare process quality for similar protective layers.

What kind of materials/products/industries will use metal coating salt spray test chamber?

Automotive, electronic component, metal materials, marine, aerospace and paint/coating, etc.

How many test methods does metal coating salt spray test chamber have?

There are four test methods as following mentioned:

* NSS test (neutral salt spray test) is the widely used accelerated corrosion test method. It adops 5% saline solution with PH value of 6~7, test temperature is 35℃, precipitation of salt spray is 1~2ml/80cm/hr.

* ASS test (acetic acid salt spray test) is developed based on NSS test. Adding some glacial acetic acid into saline solution, and make the PH value of solution to be 3, then solution becomes acidic solution, so does salt fog. Its corrosion speed is 3 times faster than NSS test.

* CASS test(copper-accelerated acetic acid-salt spray test) is a kind of fast salt spray corrosion test, add some copper salt into saline solution, test temperature is 50℃, its corrosion speed is about 8 times than the NSS test

Features:

1. Adopt automatically add water system, can watered by itself while lack of water.

2. Precise glass spray nozzle, good uniformity, mist dropping naturally, no Na-Cl crystallized salt.

3. Double over-heat protection devise and alarm when water short storage to ensure use safety.

4. Digitally temperature controller, PID controlled.

5. Tapered Spray tower, even mist dropping.

6.Applicable fields including automobile parts, aviation equipment, photographic equipment, building materials, electricity,

electrical and electronic systems.

7. Comply with ASTM B-287, JIS D-0205, H-8681, Z-2371, K-5400,etc.

Metal coating salt spray test chamber is used to inspect salt corrosion ability of materials and protective layers through

simulating ocean climate, compare process quality for similar protective layers.

What kind of materials/products/industries will use metal coating salt spray test chamber?

Automotive, electronic component, metal materials, marine, aerospace and paint/coating, etc.

How many test methods does metal coating salt spray test chamber have?

There are four test methods as following mentioned:

* NSS test (neutral salt spray test) is the widely used accelerated corrosion test method. It adops 5% saline solution with PH value of 6~7, test temperature is 35℃, precipitation of salt spray is 1~2ml/80cm/hr.

* ASS test (acetic acid salt spray test) is developed based on NSS test. Adding some glacial acetic acid into saline solution, and make the PH value of solution to be 3, then solution becomes acidic solution, so does salt fog. Its corrosion speed is 3 times faster than NSS test.

* CASS test(copper-accelerated acetic acid-salt spray test) is a kind of fast salt spray corrosion test, add some copper salt into saline solution, test temperature is 50℃, its corrosion speed is about 8 times than the NSS test

Features:

1. Adopt automatically add water system, can watered by itself while lack of water.

2. Precise glass spray nozzle, good uniformity, mist dropping naturally, no Na-Cl crystallized salt.

3. Double over-heat protection devise and alarm when water short storage to ensure use safety.

4. Digitally temperature controller, PID controlled.

5. Tapered Spray tower, even mist dropping.

6.Applicable fields including automobile parts, aviation equipment, photographic equipment, building materials, electricity,

electrical and electronic systems.

7. Comply with ASTM B-287, JIS D-0205, H-8681, Z-2371, K-5400,etc.

|

Exter./Inner.Material

|

P.V.C & P.P

|

|

Spray syatem

|

Air + acid (base)liquid

|

|

Heating system

|

SUS#304 & 316 stainles steel heater+taflon

|

|

Controller system

|

Hydrometer, salinometer, fog collector, glassbar

|

|

Other Components

|

Digital electronic indicator +SSR+PID

|

|

Safely Devices

|

Overheating prevention circult-breaker, dehydration and overheating prevention mechanism, breakdown indicator light

|

|

Power supply

|

AC 1 phase 220V 50/60Hz

|

|

Customization service

|

Non-standard or special requirement are all welcome

|

Products Process

Packing & Delivery

Hot Searches