- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Berlt

-

Model Number:

-

TNGA

-

Product name:

-

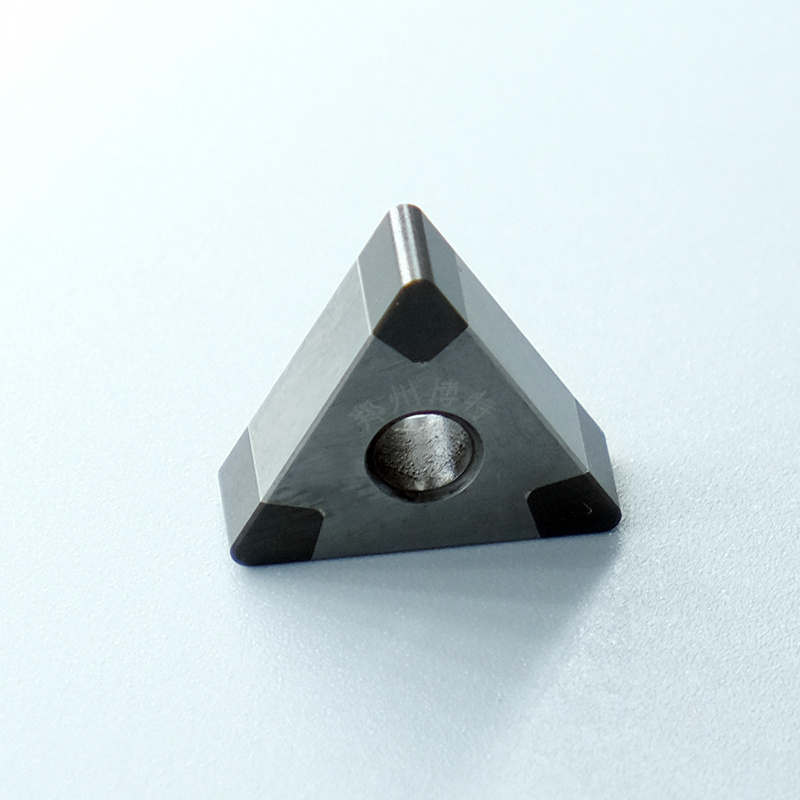

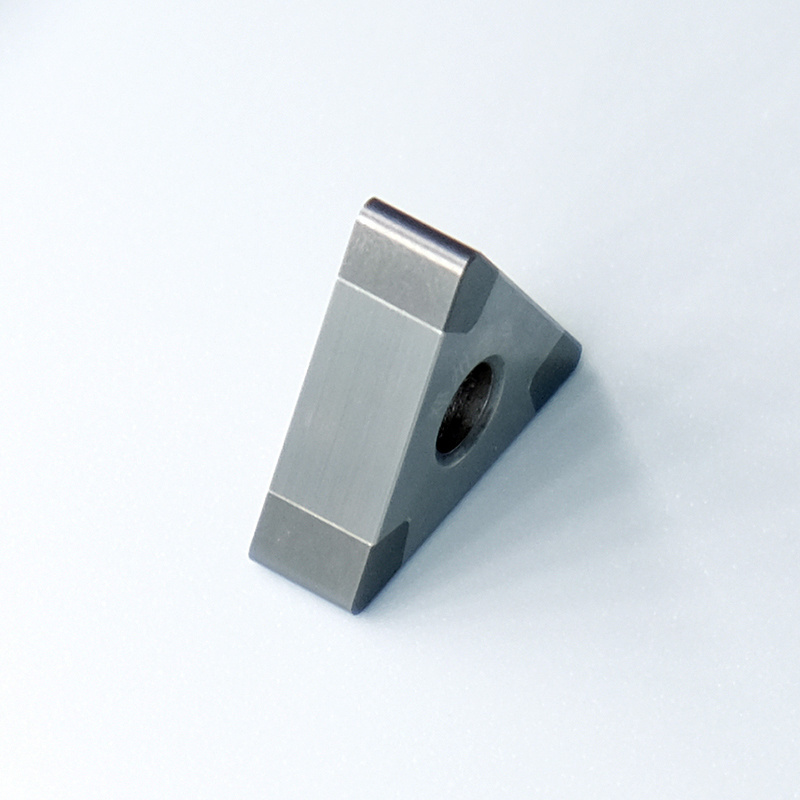

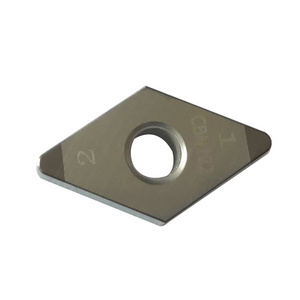

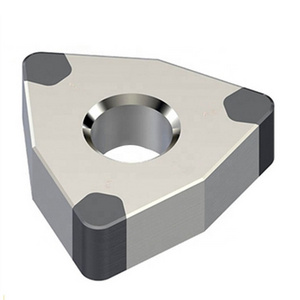

PCBN CUTTING TOOLS

-

Application:

-

Internal/External Turning Inserts

-

Material:

-

CBN(cubic boron nitride)

-

Type:

-

Cnc Tool Parts

-

Workpiece Material:

-

cast iron / hard steel

-

Machining model:

-

Rough/Semi-finishing/ Finishing

Quick Details

-

Usage:

-

External Turning Tool, Internal Turning Tool

-

Hardness:

-

Super Hard

-

Coating:

-

Uncoated

-

Warranty:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Berlt

-

Model Number:

-

TNGA

-

Product name:

-

PCBN CUTTING TOOLS

-

Application:

-

Internal/External Turning Inserts

-

Material:

-

CBN(cubic boron nitride)

-

Type:

-

Cnc Tool Parts

-

Workpiece Material:

-

cast iron / hard steel

-

Machining model:

-

Rough/Semi-finishing/ Finishing

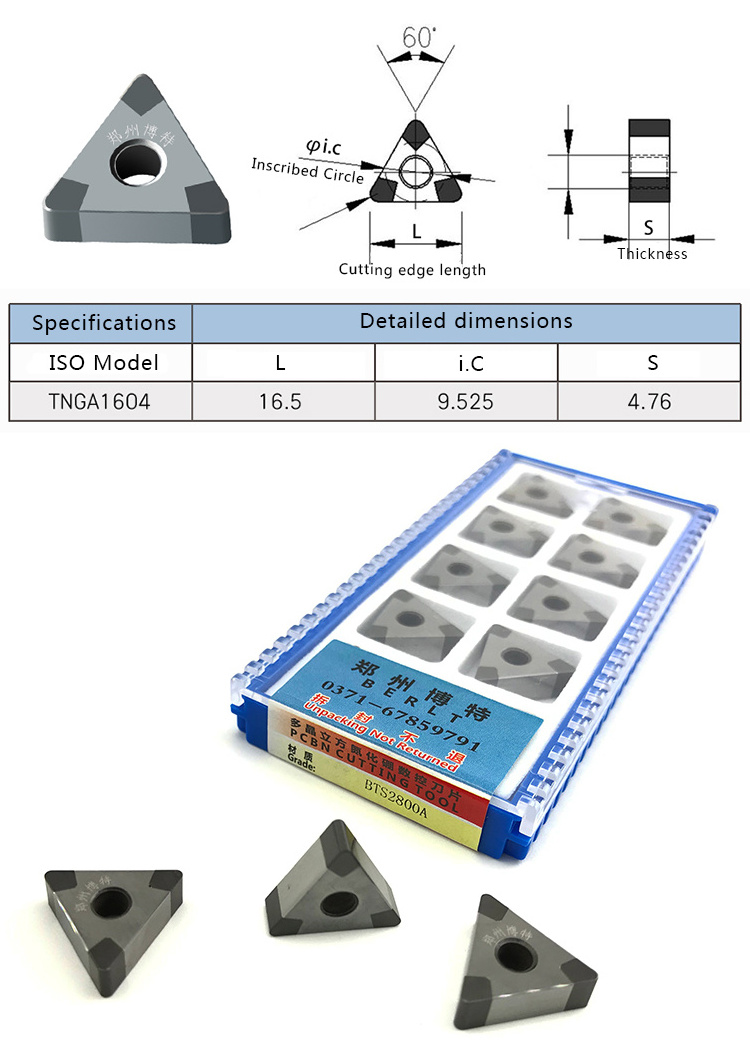

Products Description

|

Product name

|

PCBN CUTTING TOOLS

|

|

|

|

|||

|

Model Number

|

TNGA

|

|

|

|

|||

|

Material

|

CBN(cubic boron nitride)

|

|

|

|

|||

|

Feature

|

Excellent impact resistance/ good wear resistance/for roughing finishing

|

|

|

|

|||

|

MOQ

|

10PCS

|

|

|

|

|||

Our Advantages

Berlt PCBN blade has both strong wear resistance and high impact resistance. It can also be used for rough machining at low speed and medium speed.

PCBN blade has good wear resistance and strong impact resistance, which can meet high-speed cutting, save man hours and improve machining efficiency. PCBN blade is widely used to process high hardness and difficult to process materials, including cast iron (gray cast iron, alloy wear-resistant cast iron, high chromium cast iron, nodular cast iron, chilled cast iron), hard steel (quenched steel, wear-resistant steel, bearing steel, high-speed steel, high manganese steel) and other materials.

★ More cost-effective

The service life of the blade is several times to more than ten times that of the cemented carbide tool, which reduces the number of tool changes in production and processing, improves the processing efficiency and reduces the comprehensive production cost.

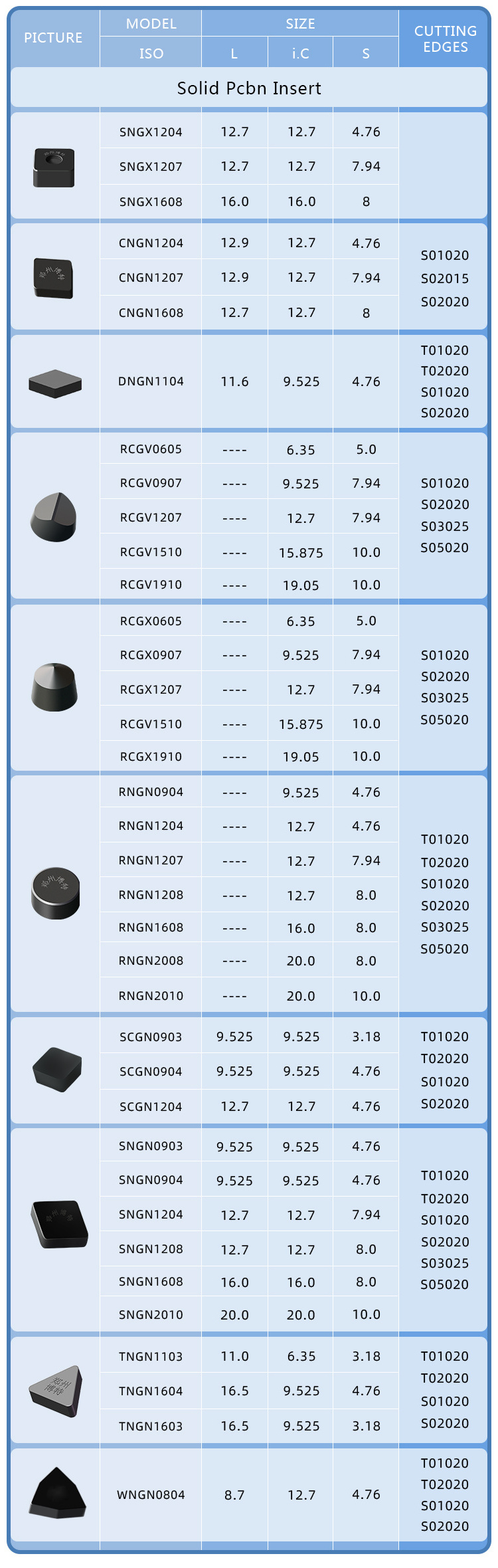

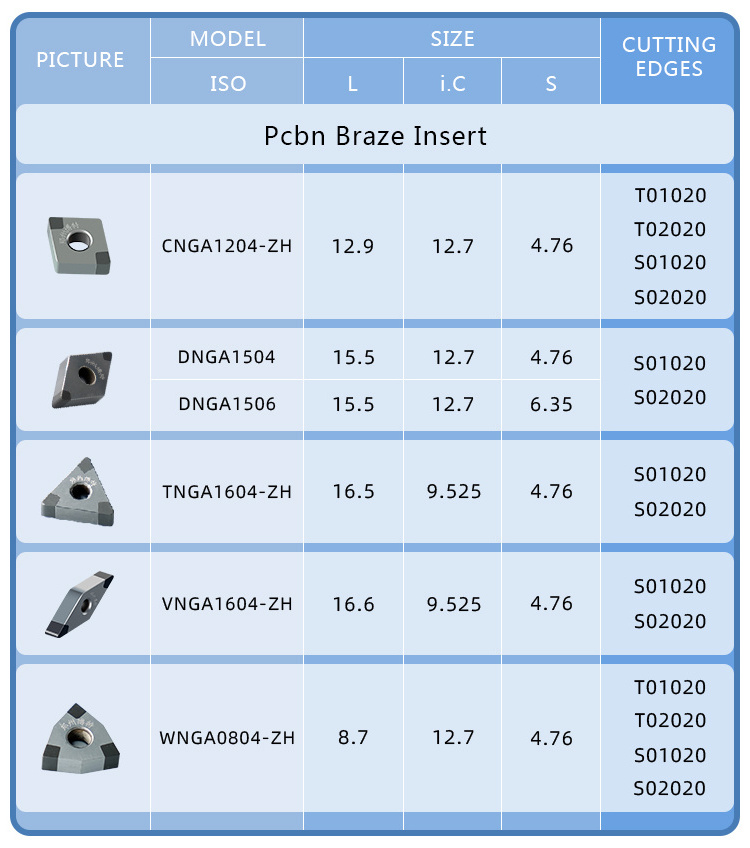

★ More options

The cutting tools have complete models and various brands, which are suitable for processing different materials; The blade edge processing is diversified and refined to better meet the needs of users.

★ Higher processing efficiency

PCBN blade has good wear resistance and strong impact resistance, which can meet high-speed cutting, save man hours and improve machining efficiency.

The service life of the blade is several times to more than ten times that of the cemented carbide tool, which reduces the number of tool changes in production and processing, improves the processing efficiency and reduces the comprehensive production cost.

★ More options

The cutting tools have complete models and various brands, which are suitable for processing different materials; The blade edge processing is diversified and refined to better meet the needs of users.

★ Higher processing efficiency

PCBN blade has good wear resistance and strong impact resistance, which can meet high-speed cutting, save man hours and improve machining efficiency.

Multiple Choice

|

Grade

|

|

Machining model

|

Workpiece material

|

Applicable industry

|

|

|

BTS2800

|

|

Rough/ Semi-finishing

|

★ Grey cast iron ★ Alloy cast iron |

★ Engine

★ gearbox ★ pulley ★ Flywheel ★ brake disc ★ brake drum ★ Industrial pumps |

|

|

BTS3800

|

|

Rough/ Semi-finishing

|

★ Cast hard steel

★ Alloy cast iron

★ hss |

★ rollers

★ brake disc ★ brake drum |

|

|

BTS7800

|

|

finishing

|

★ Grey cast iron

★ Alloy cast iron

★ Ductile iron |

★ brake disc

★ brake drum

★ automobile wheel hub ★ crank shaft |

|

|

BTS6000

|

|

finishing

|

★ forged hard steel

★ cast hard steel

|

★ Ball screw

★ gear, bearing

★ Hub unit ★ ball cage ★ transmission shaft |

|

Application

For turning and milling of rolls, industrial pumps, brake discs, brake drums, compressor parts, gears, bearings, mining machinery.

Manufacturing & Inspetion Process

Hot Searches