- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

1200

-

Weight (KG):

-

5600 kg

-

name:

-

shredder

-

model:

-

mc-1200

-

Voltage:

-

380v

-

power:

-

45kw*2

-

spindle speed:

-

18r/min

-

number of cutters:

-

28

-

particle size:

-

3-10mm

-

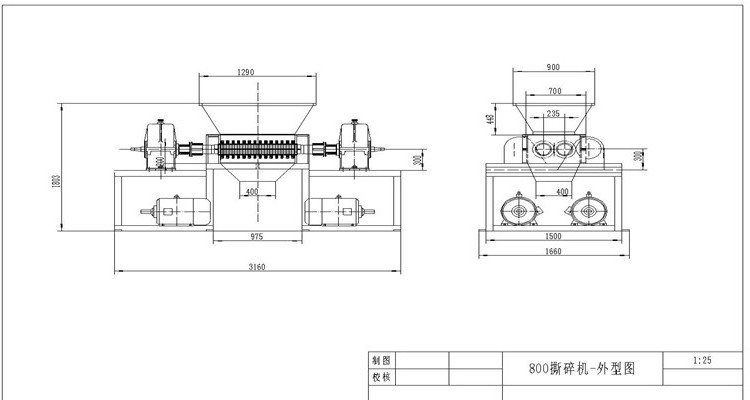

dimension:

-

6400*2200*3000

-

weight:

-

5600kg

-

Application:

-

Recycled Industry

Quick Details

-

Production Capacity:

-

3-5t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MC

-

Model Number:

-

1200

-

Weight (KG):

-

5600 kg

-

name:

-

shredder

-

model:

-

mc-1200

-

Voltage:

-

380v

-

power:

-

45kw*2

-

spindle speed:

-

18r/min

-

number of cutters:

-

28

-

particle size:

-

3-10mm

-

dimension:

-

6400*2200*3000

-

weight:

-

5600kg

-

Application:

-

Recycled Industry

double shaft shredder tire shredding machine tire shredder Application

Paper: newspaper, cardboard, corrugated paper, copy paper;

Barrel products: plastic barrels, metal barrels, paint buckets, IBC barrels, trash cans;

Plastic products: plastic bags, woven bags, plastic bottles, plastic frames, plastic cans;

Metal products: aluminum profiles, oil filters, cans, metal cans;

Electronic appliances: refrigerator casing, circuit board, laptop casing, TV casing, CD disc;

Glass products: glass wool, glass, glass bottles;

Wood: wood trim, wooden pallets, solid wood, branches;

Other: rubber products, textiles.

|

Model

|

MC-600

|

MC-800

|

MC-1000

|

MC-1200

|

MC-1600

|

MC-1800

|

MC-2000

|

|

Spindle power(Kg)

|

15*2

|

22*2

|

37*2

|

45*2

|

55*2

|

75*2

|

90*2

|

|

Spindle speed(r/min)

|

20

|

20

|

18

|

18

|

18

|

18

|

18

|

|

Yield(t/h)

|

0.8-1.0

|

1.0-1.5

|

2.5-3.0

|

3.0-5.0

|

5.0-8.0

|

8.0-10.0

|

10.0-15.0

|

|

Number of cutters

|

24

|

32

|

22

|

28

|

49

|

44

|

50

|

|

Particle size

(mm) |

3.0-10.0

|

3.0-10.0

|

3.0-10.0

|

3.0-10.0

|

3.0-10.0

|

3.0-10.0

|

3.0-10.0

|

|

Silo size

(mm) |

600-800

|

800-1000

|

1000-1200

|

1200-1500

|

1600-1800

|

1800-2000

|

2000-2200

|

|

Dimension

(mm) |

3500*1500*1800

|

4800*1800*2500

|

3800*2000*2800

|

6400*2200*3000

|

6800*2300*3200

|

7300*2500*3500

|

8000*2800*3800

|

|

Weight(Kg)

|

3200

|

3800

|

4800

|

5600

|

6200

|

7000

|

8000

|

The main advantages of the crusher

1) Efficient: material shredding rate is about 95%, higher than the general shredder;

2) Energy saving: heavy duty hard magnetic surface reducer, YF-3 type motor, low power consumption, high torque;

3) Environmental protection: equipped with professional dust removal equipment, the dust removal rate is up to 99%;

4) Durable: The tool is made of H13 and Cr12MoV with high wear resistance.

Different types of knife rollers