- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vacorda Level Switch

-

Model Number:

-

UHK-Float Level Switch

-

Material:

-

Stainless steel, 304

-

Mode:

-

Contact switch

-

Protection grade:

-

IP65

-

Temerature:

-

-196~250℃

-

Signial output:

-

switching sgnial,4-20mA

-

After service:

-

twelve months

-

Certificate:

-

ISO9001:2000

-

Pressure:

-

16MPa

-

Contact type:

-

SPST, SPDT

-

Detect point:

-

8 switch detect 8 point

-

Product name:

-

Radio Frequency Liquid Level Sensor Capacitive Liquid Level Switch

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 Year

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Vacorda Level Switch

-

Model Number:

-

UHK-Float Level Switch

-

Material:

-

Stainless steel, 304

-

Mode:

-

Contact switch

-

Protection grade:

-

IP65

-

Temerature:

-

-196~250℃

-

Signial output:

-

switching sgnial,4-20mA

-

After service:

-

twelve months

-

Certificate:

-

ISO9001:2000

-

Pressure:

-

16MPa

-

Contact type:

-

SPST, SPDT

-

Detect point:

-

8 switch detect 8 point

-

Product name:

-

Radio Frequency Liquid Level Sensor Capacitive Liquid Level Switch

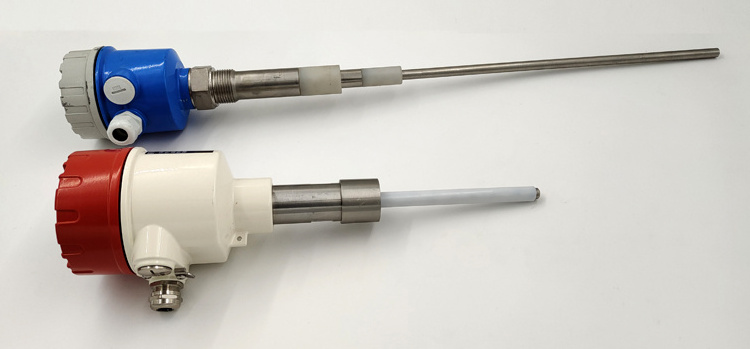

Radio Frequency Capacitive Float Less Level Switch Vertical Mounted Level Switch

The RF admittance level instrument is developed from the capacitive level measurement technology. It is a level control detection instrument with anti-hanging material, more reliable, more accurate and wider applicability. RF admittance is a combination of resistive, capacitive, and inductive components.

RF admittance level control technology is to achieve level measurement by measuring the admittance of the measured medium with high frequency radio waves. The difference between RF admittance technology and capacitive technology lies in the diversity of measurement quantity and three-electrode technology. A shield electrode is added between the measurement electrode and the ground electrode to protect the halo electrode from the influence of the hanging material, and the measurement is more stable. Accurate and reliable.

When the position of the material changes, the three-electrode signal processing circuit compares the comprehensive change signal of impedance, capacitive reactance and inductive reactance with the reference signal. When the difference between the two signals reaches a certain level, the output state of the relay changes, thereby detecting Level changes.

Features

1.Anti-adhesion: unique circuit design and sensor structure can eliminate the influence of the measurement of the material on the probe, and automatically correct it, avoiding false measurements and signals, and no need to clean the probes regularly;

2.Maintenance-free: The switch can be moved by mistake, no mechanical wear, no maintenance required;

3.Strong anti-interference: contact measurement, 0.3 second delay can eliminate the influence of material fluctuation;

4.Strong adaptability: can detect powder, particles, liquid, viscous, conductive, non-conductive materials.

Application

1.Power industry: coal transportation, ash removal system (ash bucket, warehouse pump, ash storage)

2.Building materials industry: such as cement plants

3.Food industry: flour cans, packaging hoppers

4.Pharmaceutical industry: various raw materials storage silos, ingredient mixing tanks, etc.

5.Paper industry: sawdust bin, liquid tank

Technical Parameters

|

Probe material |

SS304, SS316L, etc. |

|

Probe pressure |

Max 5 .0 MPa |

|

Sensitivity |

0.5PF; |

|

Material temperature |

-184 ~ 350 ℃ |

|

Switching delay |

T he delay range is adjustable from 0 to 30 seconds; |

|

Mounting interface |

1"NPT, 3/4" NPT or customer flange |

|

Electrical interface |

M20*1.5, 1/2 "NPT |

|

Working power |

220VAC, 24VDC; |

|

Alarm form |

optional upper or lower limit alarm ; |

|

Output signal |

R elay output |

|

Contact form |

SPDT (1 SPDT); |

|

Contact capacity |

220VAC 5A; |

|

Power consumption |

2.5W max; |

|

Ambient temperature |

-40 ~ 80 ℃ ; |

|

Protection level |

IP65; |

|

Explosion-proof grade |

Exia Ⅱ CT5Ga, ExidⅡ CT5Gb |

Product installation

Product Application

Sichuan VACORDA Instruments Manufacturing Co., Ltd.is a professional production-manufacturing enterprise specialized in designing, producing and marketing of instruments and apparatuses. Our company has been established for 23 years since 1997 to grow up to be a team of high-quality, united, hard-working and truth-seeking characters. Solid foundation has been established.

In 2017, we moved into our new factory whhich occupies the area about 20000 square meter, the workshop of 6900 square meter, R&D department of 1180 square meter , integrated office building of 1260 square meter, and we have established the high accuracy flow calibration lines.

Our company has got the ISO9001: 2000 international quality system certification in 2005, Import and export trading right in 2012, total 12 patents till 2016, the title of “national high-tech enterprise” and CE certificate for three categories product in 2014. Our company has owned trade marks as “vacorda”. At the same time, our company is preparing for more certificates for foreign market, such as IECEX, API, UL and so on, to lay a foundation for further international market.

Workshop and Skilled Workers

Certification and Equipment

Why Choose Us:

1.

23 years

of instrumentation equipment production experience

2. Product support

OEM / ODM

, export to more than

100

countries

3. The company area

20,000

square meters, and

150+

orders per month

4. Provide email, skype, whatsapp 24-hour one-on-one

technical support service

online

Q: The new magnetic flap liquid level gauge can't show liquid level?

A: 1.check whether there is block in by pass pipe 2.check the the density of medium 3.check whether the float ball is stucked by float ball.

Q: The longest length of magnetic flap liquide level gauge?

A: the length is customized,but in order to be convenient for transport,if the length is over 6m,we recommend

Q: If the float ball is installed at the wrong opposite direction,what's the influence?

A: reading level will be higher than true level,usually higher by length of floatball-70mm

Q: What's installation details of magnetic flap liquid level gauge ?

A: 1.before installation,check specification with label plate. 2.There shouldn't magnetic field within 400m

Q: There is problem in output signal 4--20mA?

A: 1.Check working power supply 2.check wiring 3,check load resistance 4.verify measuring range,zero point

Q: What's specification we need to know before purchasing magnetic flap liquid level gauge?

A: medium density,working temperature,working pressure,material,flange center to center distance,flange standard,whether need 4--20mA output signal;wether need level alarm