- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

lanyu

-

Voltage:

-

220V/380V, 220V-440V

-

Dimension(L*W*H):

-

1470/1370/1600cm

-

Weight (KG):

-

550 kg

-

Raw material:

-

Sand

-

Product Name:

-

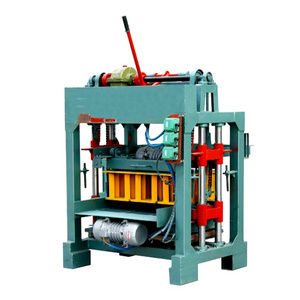

Automatic Concrete Making Machine

-

Color:

-

Can customize

-

Name:

-

brick machine

-

Block Type:

-

cement brick making machine

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online Support

-

Products:

-

Hollow Brick Solid Brick

-

Molding cycle:

-

40s

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 2000-10000 PCS /8 hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

lanyu

-

Voltage:

-

220V/380V, 220V-440V

-

Dimension(L*W*H):

-

1470/1370/1600cm

-

Weight (KG):

-

550 kg

-

Raw material:

-

Sand

-

Product Name:

-

Automatic Concrete Making Machine

-

Color:

-

Can customize

-

Name:

-

brick machine

-

Block Type:

-

cement brick making machine

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online Support

-

Products:

-

Hollow Brick Solid Brick

-

Molding cycle:

-

40s

automatic brick machine/automatic brick machine price/fly ash brick machine

The work of the mobile brick machine requires a smooth and hard working site with a concrete thickness of 80-100mm. Square flatness is generally not more than 5 mm (to ensure that the height of the block is accurate) each need to work 400-500 square meters.

This machine is mainly composed of frame and walking part, mold part, stripping system, steering mechanism, electrical control and other parts. The frame is welded into a trapezoidal structure with Angle iron, good rigidity, and the walking wheel is rotated by the whole shaft, which is light and flexible with good linearity. The mould part is composed of mould box, mandrel and press head, so the mould can be changed at any time according to the need of production. A vibrator is installed on the mandrel and the press head to ensure the density of the block meets the requirements. The demoulding system adopts worm wheel drive, steel wire rope lifting demoulding, compact structure, safe and stable. The automatic walking part adopts the tooth bar and the tooth wheel transmission, the machine body moves forward automatically when the mold is released. Electrical control part of the structure is simple, easy to operate, operators can quickly master. Simple structure and convenient operation.

1. Not using the clay as raw material to destroy any field.

2. Making use of three industrial wastes to change wastes into valuables.

3. Not using fire to bake blocks and not building kiln to save the energy sources and fields.

4. No chimney to protect the environment and avoid pollution.

5. Production process is simple they can be made everywhere .

6. Low investment and achieving much faster results customers can profit in half a year after investing.

7. The block can be produced all around the year.

8. Good looking construction convenient low-floor real jigsaw puzzle and the high buildings do filler and cheap.

9. Technical criteria is better than those of red brick and green brick.

1. 4-35 mobile block making machine can produce various different concrete blocks by changing molds.

2. Precise line cutting and carburizing treatment technology are adopted to prolong the moulds service life.

3. This model is made of high-performance steel Q345 selected according to international CE standard. Thus it has

advantages in high toughness, wear and tear resisting and high strength.

4. Equipped with two wheels, you can move it easily to anywhere you want.

5. Low cost and easy operation made this machine is suitable for individuals small and enterprises

Q1:How to use this machine?

A:As a professional manufacturer,we have many professional engineers, they will go to clients’ site for guiding the installation and test-running;also can teach you how to use properly.

Q2:Can you sent me some spare parts freely?

A:Generally speaking,we usually sent customers the wearing parts when shipping the product, but if you have a large order,we will consider to sent you some spare parts freely

Q3: What is the delivery time?

A: About 20-25work days after receiving advance payment

Q4: What is the payment terms?

A: T/T. L/C are all accept.