- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

QIANFENG

-

Outer Diameter:

-

1 - 140 inch

-

Thickness:

-

1 - 100 mm

-

Grade:

-

q235,q345,10#,20#

-

Delivery Time:

-

7-10 DAYS

-

Ends:

-

Plain Ends Bevel Ends

-

Brand:

-

QIANFENG

-

End protector:

-

Plastic Pipe Cap Iron Protector

-

Surface:

-

Customers't Requirement

-

Package:

-

Seaworthy Standard Package

-

Color:

-

as Customers' Requirement

-

MOQ:

-

1 Ton

-

Payment Term:

-

L/C T/T (30%DEPOSIT)

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±5%

-

Oiled or Non-oiled:

-

Non-oiled

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

QIANFENG

-

Outer Diameter:

-

1 - 140 inch

-

Thickness:

-

1 - 100 mm

-

Grade:

-

q235,q345,10#,20#

-

Delivery Time:

-

7-10 DAYS

-

Ends:

-

Plain Ends Bevel Ends

-

Brand:

-

QIANFENG

-

End protector:

-

Plastic Pipe Cap Iron Protector

-

Surface:

-

Customers't Requirement

-

Package:

-

Seaworthy Standard Package

-

Color:

-

as Customers' Requirement

-

MOQ:

-

1 Ton

-

Payment Term:

-

L/C T/T (30%DEPOSIT)

|

PRODUCT PROPERTIES

|

|

|

|

|||

|

Product Name

|

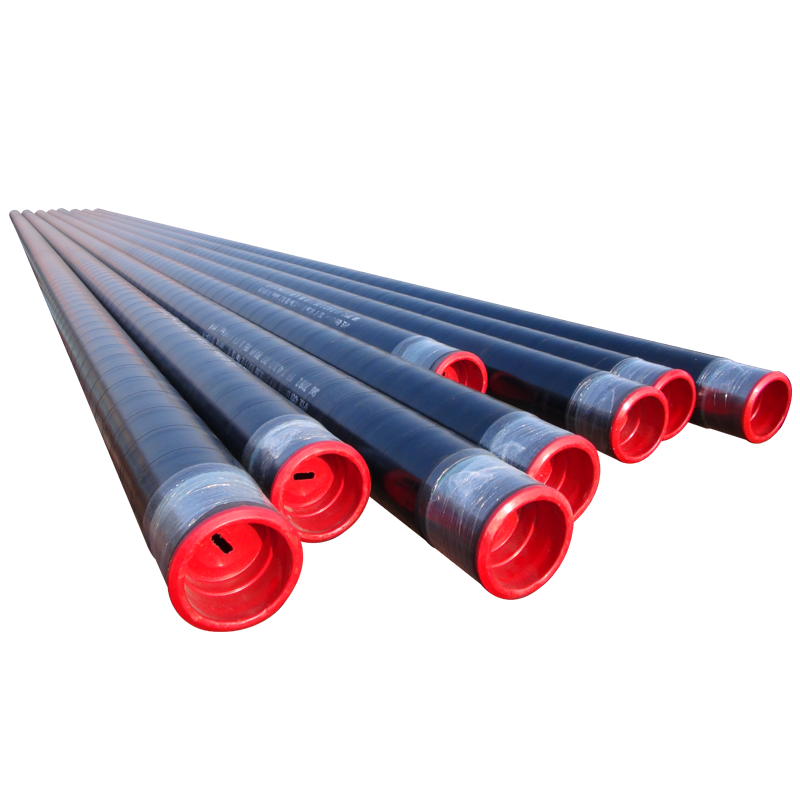

2PE ANTICORROSIVE PIPE

|

|

|

|||

|

Length

|

6m-12m ,or by customer's requirements

|

|

|

|||

|

Outer Diameter

|

8"-88"

|

|

|

|||

|

Wall Thickness

|

2-70mm

|

|

|

|||

|

Laid way

|

Buried

|

|

|

|||

|

Application

|

Water,oil gas, Coal to gas

|

|

|

|||

|

Production Standard

|

The national standard GB/T23257-2009

|

|

|

|||

|

INDEXES OF ANTI-CORROSIVE LAYER

|

|

|

|

|||

|

Item

|

Indexes

|

|

|

|||

|

Peel strength(N/cm)

(20℃±10℃)/(50℃±5℃) |

≥70

≥35 |

≥100(cohesive failure)

≥70 (cohesive failure) |

|

|||

|

Cathodic disbonding

(65℃,48h)/(mm) |

≤15

|

≤6

|

|

|||

|

Cathodic disbonding(the highest temperature,30d)/(mm)

|

≤25

|

≤15

|

|

|||

|

Impact strength(J/mm)

|

≥8

|

/

|

|

|||

|

Counter bending(-20℃,2.5°)

|

No crack

|

/

|

|

|||

|

NO

|

ITEM

|

INDEXES

|

|

|

|

1

|

Density (g/m3)

|

0.920~0.950

|

|

|

|

2

|

MFR(190℃,2.16kg)/(g/10min)

|

≥0.7

|

|

|

|

3

|

Vicat Softening Point(℃)

|

≥90

|

|

|

|

4

|

Brittle Temperature(℃)

|

≤-50

|

|

|

|

5

|

Oxidation Induction time(OIT)(200℃)/(min)

|

≥10

|

|

|

|

6

|

Moisture Content(%)

|

≤0.1

|

|

|

|

7

|

Tensile Strength(MPa)

|

≥17

|

|

|

|

8

|

Elongation At Break (%)

|

≥600

|

|

|

Package Details.

End With Plastic Cap covered,Wrapped with rope by bulk,in container or as request

Shippment.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

|

Trade Terms

|

FOB,EXW,CIF,CNF

|

|

|

||

|

MOQ

|

20 TONS

|

|

|

||

|

PORT

|

XINGANG PORT

|

|

|

||

|

SHIPPMENT

|

BY SEA,BY EXPRESS OR BY AIR

|

|

|

||

|

PAYMENT TERMS

|

T/T,L/C AT SIGHT,PAYPAL

|

|

|

||

|

PAYMENT CONDITION

|

30% BEFORE PRODUCTION,70% BEFORE DELIVERY OR 70% AGAINST B/L

|

|

|

||

|

Service

|

OEM,ODM or Customized

|

|

|

||

ISO9001.

National Quality Management System Certification

ISO14001.

Environment Management System Certification

OHSAS18001.

Occupational Health And Safety Management System Certification

Tianjin Qianfeng Anticorrosion And Insulation Steel Pipe Co.,Ltd established in 2004, is specializing in producing all kinds of anti-corrosion and insulation steel pipes.Our company covers the area of 180 mu, building area is 26000 square meter, registered capital US dollar 20 million, fixed asset input is US dollar 26 million, has employed 180 personnel, all kinds of professional and technical personnel more than 40 people.

The main products : 3PE steel pipe ,FBE steel pipe ,Spigot-socket joint large diameter steel -plastic composite pipe,PU coating steel pipe, CWC steel pipe,steel pipe with cement mortar on inner wall and epoxy coal tar on outer wall,fire fighting steel pipes, mining dual-resistance steel pipe,Epoxy ceramic steel pipe, HDPE gas pipe, HDPE jacket thermal insulation steel pipe,HDPE casing pipe,and various anti-corrosive and insulating accessory fittings.

The company has abundant technical forces and perfect inspection methods, has passed the national inspection center's products quality test, by virtue of company's self and state inspection organization's technical force, our company established perfect quality management system, and cooperate with material college of Tianjin university, Tianjin University of Technology School of mechanical engineering, and Tianjin science and technology commission jointly to set up Tianjin Technology and Engineering Center for Anti-corrosion

Quality Testing.

The company has established a complete joint control system of ISO9001:2008/API Q1/PRESSURE Pipeline Components Manufacture. We implement institutionalized management, programmed operation, and achieved eight 100% qualified controlling rate, which are: 100% ultrasonic flaw detection for the material plate; 100% automatic on-line UT test after welding; 100% whole-length seam X-ray test; 100% inside weld line industrial TV test; 100% hydrostatic test; 100% X-ray film or picture record on pipe ends; 100% pipe appearance inspection, and all above tests are proceeded by quality control department. The purpose is to unsure our products to meet standard requriement and satisfy the users.