- Product Details

- {{item.text}}

Quick Details

-

Slag Content:

-

12%-20%

-

Classification:

-

COM/STD/HA/HZ

-

Bulk Density:

-

200~260kg/cm3

-

Modulus of Rupture:

-

0.2Mpa

-

Al2O3:

-

39%-45%

-

Fe2O3:

-

0.2%-1.0%

-

Al2O3+SiO2:

-

45%-53%

-

Sample:

-

Avaliable

Quick Details

-

Feature:

-

Fireproof

-

Color:

-

Pure White

-

Classification Temperature:

-

1050℃-1430℃

-

Slag Content:

-

12%-20%

-

Classification:

-

COM/STD/HA/HZ

-

Bulk Density:

-

200~260kg/cm3

-

Modulus of Rupture:

-

0.2Mpa

-

Al2O3:

-

39%-45%

-

Fe2O3:

-

0.2%-1.0%

-

Al2O3+SiO2:

-

45%-53%

-

Sample:

-

Avaliable

|

Product Name

|

Ceramic Fiber Modules

|

|

Description

|

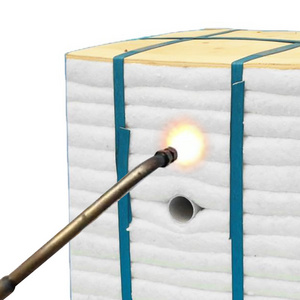

Ceramic fiber modules are a new type of refractory lining products for simplifying and speeding up the construction of kiln and improving the integrity of furnace lining.

The product is white and regular in size, and can be directly fixed on the anchor nail of the furnace shell of industrial kiln, which has good refractorily and heat insulation effect,

improves the integrity of refractorily and heat insulation of kiln.

|

|

Model

|

COM/STD/HA/HZ

|

|

Features

|

1. Low thermal conductivity, low heat capacity;

2. Excellent thermal stability, thermal shock resistance;

3. Excellent heat flow resistance and high mechanical strength;

4. Excellent elasticity, compensating for the shrinkage of the fiber lining, thereby improving the thermal insulation performance of the fiber lining;

5. Easy and quick installation, built-in anchors, good safety performance.

|

The ceramic fiber modules are made of the corresponding fiber blanket by special machining. A certain proportion of compression is maintained in the production process of the module to ensure that after the completion of masonry, the expansion of different directions will be consistent, and squeezing each other into a seamless whole.

|

INDEX

|

COM

|

STD

|

HA

|

HZ

|

|||

|

Classification Temperature(℃)

|

1050

|

1260

|

1360

|

1430

|

|||

|

Slag Content(%) ≤

|

20

|

15

|

15

|

12

|

|||

|

Bulk Density(kg/m3)

|

|

200~260

|

|

|

|||

|

Permanent Linear Change×24h(%)

|

-4/1000℃

|

-3/1000℃

|

-3/1200℃

|

-3/1350℃

|

|||

|

Al2O3(%) ≥

|

44

|

45

|

50

|

39

|

|||

|

Fe2O3(%) ≤

|

1.0

|

1.0

|

0.2

|

0.2

|

|||

|

SiO2(%) ≤

|

53

|

52

|

49

|

45

|

|||

|

ZrO2(%) ≥

|

|

|

|

15

|

|||

|

Regular Size(mm)

|

300L*300W*300H

|

|

|

|

|||

2. Ceramic shuttle kilns, horseshoe kilns, tunnel kilns and other ceramic kilns, kiln cars, kiln doors; energy-saving red brick kilns, shale brick kilns, etc.;

3. Petrochemical cracking furnace, reformer, atmospheric and vacuum furnace, coking furnace, flue;

4. Other types of industrial furnaces, such as soaking furnaces, crucible furnaces, resistance furnaces and other high-temperature thermal equipment.

1. Inner plastic bag and carton outside;

2. Inner plastic bag and packed on pallets;

3. Inner plastic bag and carton outside, after will be packed on pallets.

FAQ

Q1: Are you a manufacturer or a trader?

A1: We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

Q2: How do you control your quality?

A2: For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Q3: What is your delivery time?

A3: Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Q4: Do you provide free samples?

A4: Of course, we provide free samples.

A4: Of course, we provide free samples.

Q5: Can we visit your company?

A5: Yes, of course, you are welcome to visit RBT company and our products.

Q6: What is the MOQ for trial order?

A6: There is no limit, we can provide the best suggestion and solution according to your situation.

Q7: Why choose us?

A7: We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

CONTACT US

Hot Searches