Name: Mixer

Material: Food grade stainless steel

It is used to mix raw materials. We can supply different capacities mixers to meet your demands: 30kg/batch, 50kg/batch,

100kg/batch and so on.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22kw

-

Dimension(L*W*H):

-

670*420*730mm

-

Weight:

-

1000 KG

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

macaroni making machine

-

Color:

-

Silver

-

Product name:

-

production line for macaroni pasta

-

Material:

-

Stainless Steel

-

whatsapp:

-

+8615216413539

-

Inverter:

-

Taiwan Delta

-

Main motor:

-

siemens

-

Capacity:

-

100-150kg/h

-

Shapes:

-

tube,screw short pasta

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bright

-

Voltage:

-

380V/50HZ

-

Power:

-

22kw

-

Dimension(L*W*H):

-

670*420*730mm

-

Weight:

-

1000 KG

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

macaroni making machine

-

Color:

-

Silver

-

Product name:

-

production line for macaroni pasta

-

Material:

-

Stainless Steel

-

whatsapp:

-

+8615216413539

-

Inverter:

-

Taiwan Delta

-

Main motor:

-

siemens

-

Capacity:

-

100-150kg/h

-

Shapes:

-

tube,screw short pasta

Product Description

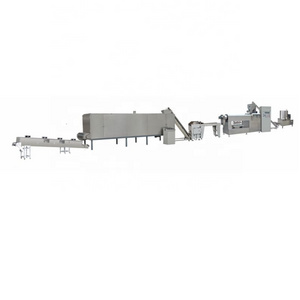

macaroni extruder production line high configuration elbow macaroni machine full pasta production line

1. Macaroni pasta production line description

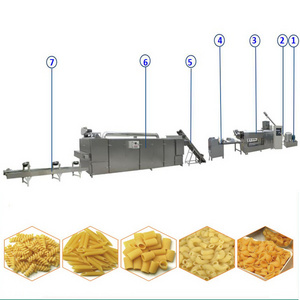

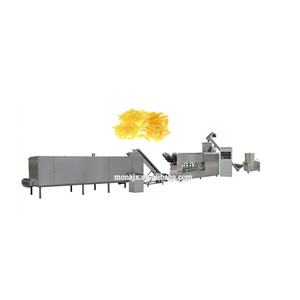

This series of Macaroni pasta production line have 3 models to product many kinds of food, such as spaghetti, shells shape crisp, tremella shape crisp, pentagon shape crisp, cat ear shape crisp, macaroni, crust of cooked rice, chromium winding noodle. And we can also make the model according to customers' requirements.

2. Macaroni pasta production line Flow chart:

Raw material→ Mixing→ Screw conveying → Extruding → Cooling conveying → Drying → Cooling conveying

2. Macaroni pasta production line Flow chart:

Raw material→ Mixing→ Screw conveying → Extruding → Cooling conveying → Drying → Cooling conveying

|

Model

|

Instaqlled Power

|

Power Consumption

|

Capacity

|

Dimension

|

|

SSE100

|

107kw

|

80kw

|

100-150kg/h

|

15000*1200*2200mm

|

Sample

macaroni details

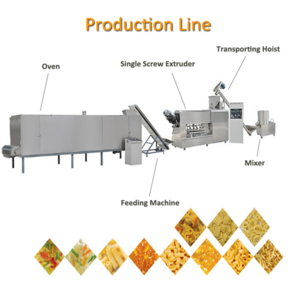

Dryer

Name: Multi-layer dryer

Material: Food grade stainless steel

We can supply dryers of different heating ways, such as steam, electric, diesel, gas etc. We can customize the multi-layer dryer

according to your specific requirements

Material: Food grade stainless steel

We can supply dryers of different heating ways, such as steam, electric, diesel, gas etc. We can customize the multi-layer dryer

according to your specific requirements

Extruder Machine

Name: pasta extruder machine

Type: Single screw extruder

With a same extruder, you can produce different shapes of pasta by changing different moulds.

Type: Single screw extruder

With a same extruder, you can produce different shapes of pasta by changing different moulds.

Stainless steel Instail capacity: 3kw Real power:3kw

Output: 200kg/h

Size: 2100*900*1500mmCut the Macaroni pasta into the length you need

Output: 200kg/h

Size: 2100*900*1500mmCut the Macaroni pasta into the length you need

Power:1.9kw

Function:Reduce material

temperature for easy packaging

Our Advantages

Company Profie

Our Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Packing & Delivery

FAQ

1. How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality

checking by yourself or by your contacts in the third party inspection organization .

2. Can your machine meet our needs well?

We will give you the proposal according to your specific requirments. Every machine is customized to meet your needs well.

3.How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to

quantity.

4. How about the after-service?

We will send 1 engineer to the buyer’s factory for a 10-day period installation and training to the operators.

5.Are you a manufacture company?

Yes,Our factory was founded in 2006 and have over 10 years experiences in this industry.Our products are hot sold all over the

world with trustworthy quality and competitive price.

6.What is the scale of your factory?

Our factory occupies a total area of 4000 square meters with over 80 wokers and 15 professional engineering..

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality

checking by yourself or by your contacts in the third party inspection organization .

2. Can your machine meet our needs well?

We will give you the proposal according to your specific requirments. Every machine is customized to meet your needs well.

3.How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to

quantity.

4. How about the after-service?

We will send 1 engineer to the buyer’s factory for a 10-day period installation and training to the operators.

5.Are you a manufacture company?

Yes,Our factory was founded in 2006 and have over 10 years experiences in this industry.Our products are hot sold all over the

world with trustworthy quality and competitive price.

6.What is the scale of your factory?

Our factory occupies a total area of 4000 square meters with over 80 wokers and 15 professional engineering..

Hot Searches