- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GEB

-

Model Number:

-

300

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

5000*2600*2200 mm

-

Weight:

-

3000 KG

-

Product name:

-

Fully Automatic Bag Making Machine

-

Application:

-

Rice Bag

-

Function:

-

Producing Plastic Bag

-

After-sales Service Provided:

-

Video Technical Support

-

Suitable material:

-

LDPE HDPE Biodegradable Film

-

Speed:

-

100-300pcs/min

-

Bag Width:

-

80-220mm

-

Type of bag:

-

PE Flat Bag

-

Certification:

-

CE/ISO9001

-

Key words:

-

woven bag machine

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Cement Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GEB

-

Model Number:

-

300

-

Voltage:

-

380v

-

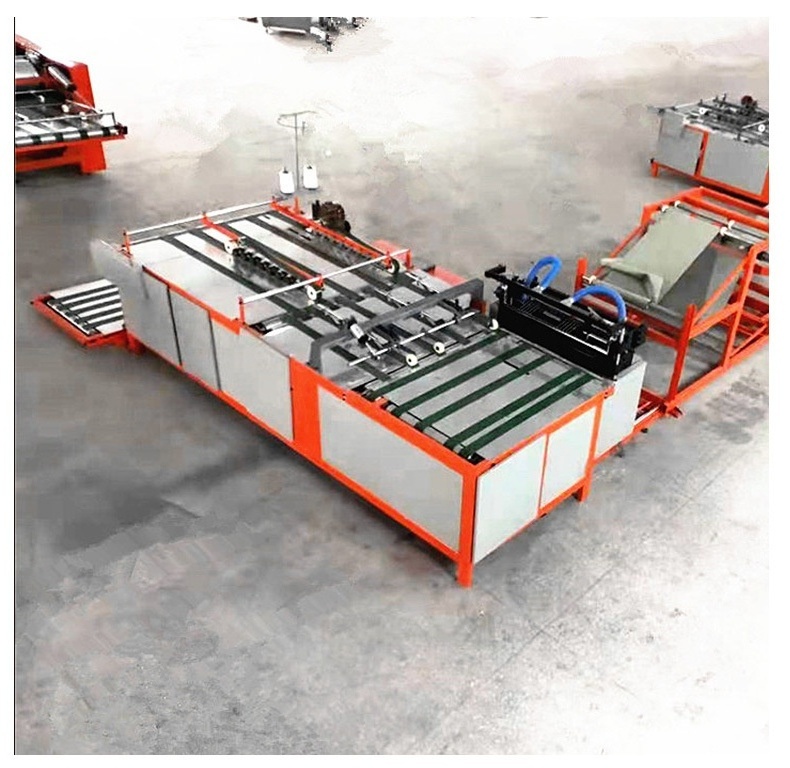

Dimension(L*W*H):

-

5000*2600*2200 mm

-

Weight:

-

3000 KG

-

Product name:

-

Fully Automatic Bag Making Machine

-

Application:

-

Rice Bag

-

Function:

-

Producing Plastic Bag

-

After-sales Service Provided:

-

Video Technical Support

-

Suitable material:

-

LDPE HDPE Biodegradable Film

-

Speed:

-

100-300pcs/min

-

Bag Width:

-

80-220mm

-

Type of bag:

-

PE Flat Bag

-

Certification:

-

CE/ISO9001

-

Key words:

-

woven bag machine

a. Small cam type and convex table as well as swing-beam rolling wheel transmission is adopted, making it easy and stable to run.

b. Slide block and rod are eliminated while the wearing parts are decreased. Rolling transmission is adopted in entire structure, which doesn't need lubricant.

c. Frequency speed regulation which is convenient and stable is adopted.

d. It is configured with automatically stop detecting unit when meeting the situation of warp/weft breaking, weft ending. The stoppage unit is sensitive and reliable.

e. It's an environmental product whose noise is not more than 80dB(A).

f. Low strength plastic yarn which is made from 100% regenerated plastic can be adopted to weave.

g. It is high-efficient and energy-efficient. The highest rotation speed of the main motor can reach 180r/min and the power is 1.5/2.2kw, which can save 10 thousand degree electricity compared with the traditional four shuttle circular loom whose power is 4kw.

h. It is a patent device

Woven bag making machine:

| Bag Width | 350-600mm |

| Bag Length | 450-910mm |

| Bag bottom width | 80-180mm |

| Value port length | 80-200mm |

| Maximum production speed | 100pcs/min |

| Maximum unwiding diameter | 1200mm |

| Power supply | 380V/3P/50HZ/A.C. |

| Installed power | 85KW |

| Dimensions(L*W*H) | 13000*8500*2500mm |

Flexographic printing machine:

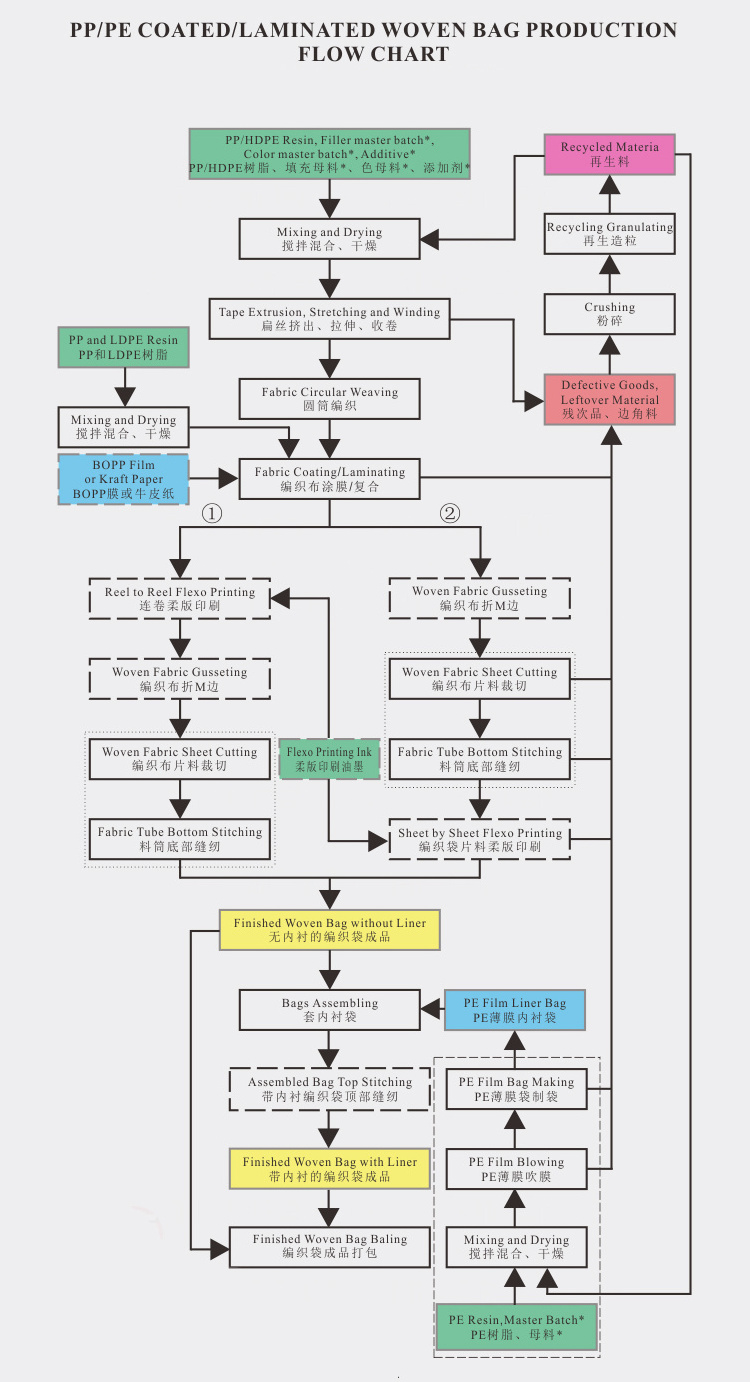

Application: The machine uses sensitization resin as flexible printing plate, suitable for printing such packing material as polyethylene and polypropylene bag, cellophane and roll paper, etc. It is a kind of idea printing equipment for producing paper packaing bag for food, supermarket handbag, vest bag and clothes bag,etc.

Plastic extrusion coating film laminating machine:

Application: To coat PP/LDPE film on PP/HDPE woven fabric, kraft paper, non-woven fabric, or laminate BOPP film, kraft paper with PP/HDPE woven fabric or non/-woven fabric.

Performances and Features: Max.working speed up to 150m/min, high efficiency, low energy consumption. Good coating adhesion for products with stable quality. Modular design with wide usage.Easy operation and maintenance, stable running, long working life.

Six shuttle circular loom:

Small cam and connecting rolling wheel transmission which is the most advanced technology is adopted, making it easy and stable to run.

Rolling transmission is adopted in entire structure instead of slide block and slide rod, which doesnt need lubricant and decreases the wearing part.

Base band belt from Italy is used, which is durable and will not break or be stretched.

It can be configured with automatically stop detecting unit when meeting the situation of warp/weft breaking,weft ending. The stopage unit is sensitive and reliable.

PLC centralized control is adopted for electric controllling, as well, frequency speed regulation which is convenient and stable.

It is higheffcient and energy economical. The higest rotaion speed of the main motor can reach 180r/min and the power is 3KW, which can save 10 thousand degree electricity compared with the traditional small-sized six shuttle circular loom whose power is 4KW.

1. Packaging:

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

1.We have more than15 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.