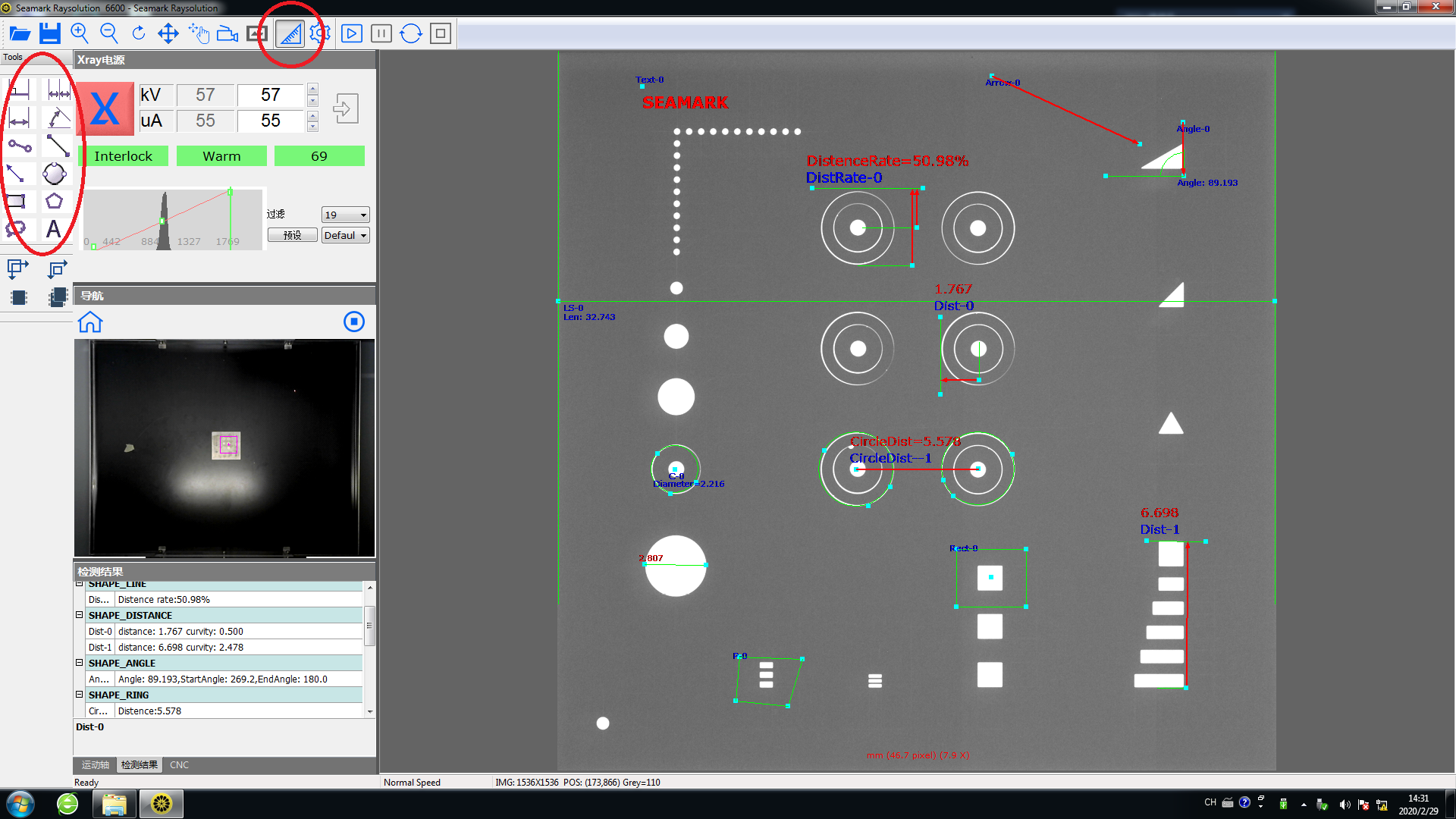

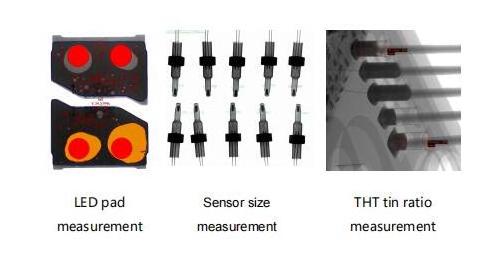

Automatic Void Ratio Calculation

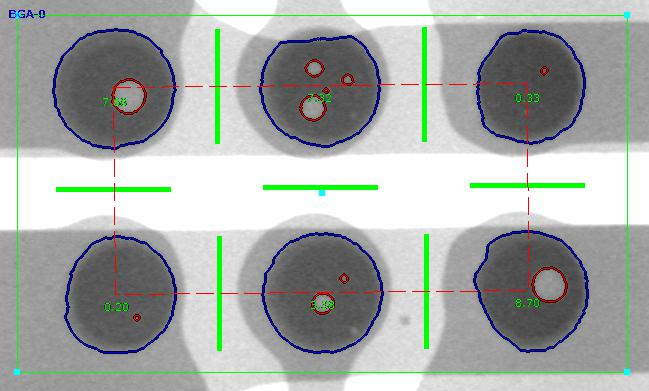

Enhanced BGA inspection function

NDX56 can quickly select and mark a single solder ball, or select the solder balls to be inspected by matrix box ; it can manually or automatically identify BGA solder balls and complete the inspection. Follow the system guidelines to easily complete the inspection process and ensure accurate and reliable inspection results.