- Product Details

- {{item.text}}

Quick Details

-

MF:

-

CHNO

-

EINECS No.:

-

None

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CH

-

Model Number:

-

Spray rigid foam

-

Product name:

-

Open cell closed cell spray foam insulation with related machine

-

Material:

-

Polyurethane PU rigid foam

-

Density:

-

45kg/CBM

-

Two Components:

-

Isocyanate MDI and Polyol

-

Fire Retardant:

-

B1, B2

-

Application:

-

Heat insulation

-

Color:

-

Brown

-

Surface:

-

Open cell and closed cell

-

Function:

-

PU spray foam

Quick Details

-

CAS No.:

-

9002-86-2

-

Purity:

-

99%

-

Other Names:

-

Rigid foam for insulation

-

MF:

-

CHNO

-

EINECS No.:

-

None

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CH

-

Model Number:

-

Spray rigid foam

-

Product name:

-

Open cell closed cell spray foam insulation with related machine

-

Material:

-

Polyurethane PU rigid foam

-

Density:

-

45kg/CBM

-

Two Components:

-

Isocyanate MDI and Polyol

-

Fire Retardant:

-

B1, B2

-

Application:

-

Heat insulation

-

Color:

-

Brown

-

Surface:

-

Open cell and closed cell

-

Function:

-

PU spray foam

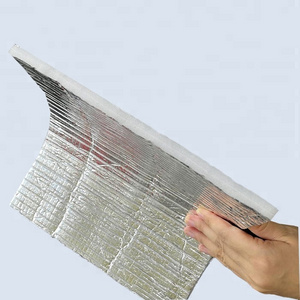

Open cell closed cell spray foam insulation with related machine

Polymeric MDI(isocyanate) and blend polyol spray foam for insulation

MDI is widely used in the production of PU rigid insulation foams and polyol isocyanate foams. Other uses include paints, adhesives, sealants, structural foams, micro-cellular integral spray foam, automotive bumper and interior parts, high resilience foam and synthetic wood on Polyurethane PU spray foam.

Physical Properties

| Appearance of spray foam | Pale yellow to brown viscous liquid |

| Hydroxyl Value mgKOH/g | 310-380 |

| Dynamic Viscosity(25℃) mpa.s | 100-200 |

| Specific gravity(20℃) g/ml | 1.12-1.20 |

| Storage Temperature ℃ | 10-25 |

| Storage Stability month | 6 |

Recommended Ratio of spray PU foam

| PBW | |

| DQT-501A blend polyols | 100 |

| Isocyanate | 100-105 |

Reactivity Characteristics of spray polyurethane foam

(The temperature of the system is 20℃, and the exact value varied depending on processing condition)

| Cream time | 3-5 |

| Gel time | 6-10 |

We can also supply spray foam machine together with the chemicals. Including high pressure and low pressure machines.Accessories: Spray foam gun, heating pump, mixing pump, storage case, etc.

We can also supply spray foam machine together with the chemicals. Including high pressure and low pressure machines.Accessories: Spray foam gun, heating pump, mixing pump, storage case, etc.

Packaging of the spray foam

250kg/drum for Isocyanate, Polymeric MDI foam

200kg/drum or 220kg/drum for blend polyol

Shipping of the spray foam

Delivered by sea, by train or by air.