Rolling continuous feeding structure,

fast response speed, closed-loop self-test

system, using high-quality encoder, it will

make sure that feeding system is

right all the time.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

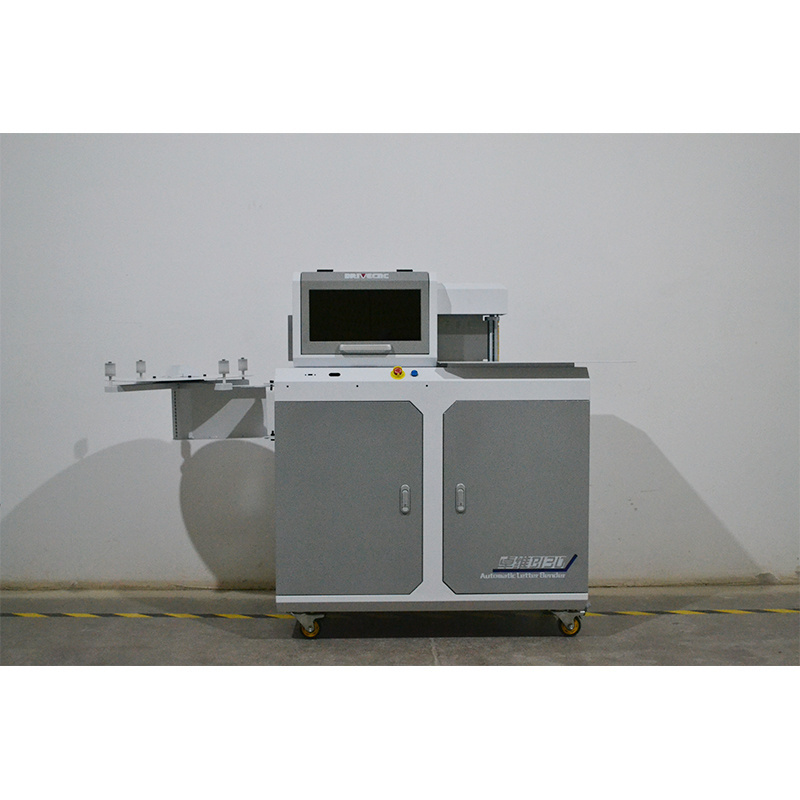

B130 Mini Aluminum Letter Bender

-

Processing material:

-

flat aluminum

-

Material thickness:

-

0.6mm

-

Max. Processed Width:

-

30mm -130mm

-

Voltage:

-

220V 50HZ

-

Power:

-

0.75KW

-

Function:

-

Auto Feeding+bending+slotting

-

Supporting software:

-

CorelDRAW / AI

-

Packing:

-

Wooden Box

-

Process file format:

-

DXF / AI / PLT

Quick Details

-

Place of Origin:

-

Shandong, China

-

Year:

-

2023

-

Weight (KG):

-

100

-

Product name:

-

B130 Mini Aluminum Letter Bender

-

Processing material:

-

flat aluminum

-

Material thickness:

-

0.6mm

-

Max. Processed Width:

-

30mm -130mm

-

Voltage:

-

220V 50HZ

-

Power:

-

0.75KW

-

Function:

-

Auto Feeding+bending+slotting

-

Supporting software:

-

CorelDRAW / AI

-

Packing:

-

Wooden Box

-

Process file format:

-

DXF / AI / PLT

Product Description

Specification

|

|

Feeding system

|

Rolling continuous feeding mechanism

|

|

|

|

|

Slotting system

|

Hard alloy milling cutter

|

|

|

|

|

Bending system

|

Two -axis linkage copper shaft roller extrusion system (non-scratch material)

|

|

|

|

|

Driving motor

|

Two -phase stepper motor 4 set / DC carbon brush motor 1 set

|

|

|

|

|

Equipment weight

|

80 KG

|

|

|

|

|

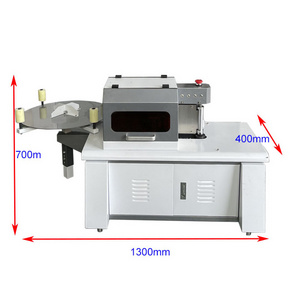

Dimensions

|

L1650*W700*H1150mm

|

|

|

|

|

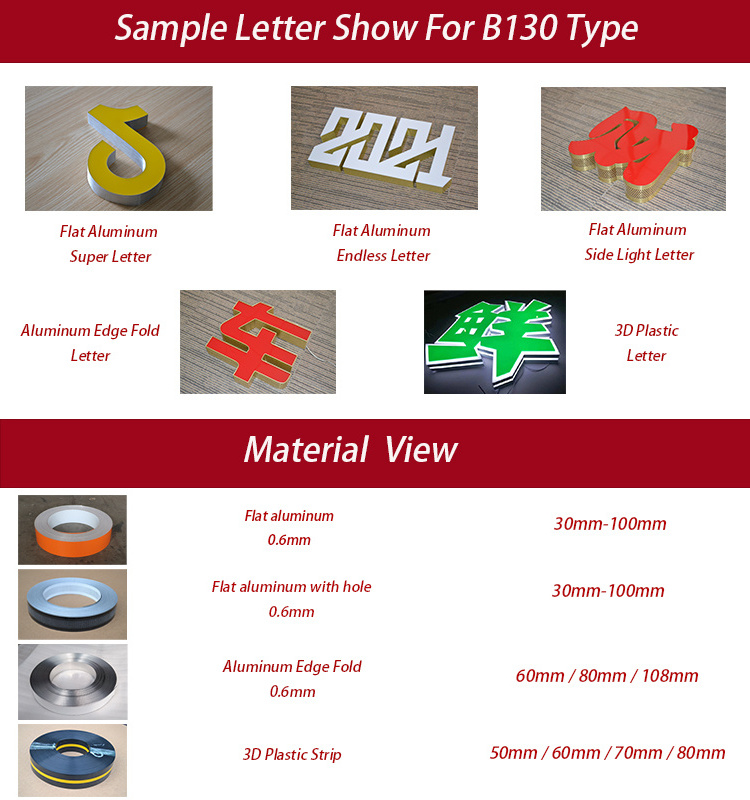

Material category

|

Flat aluminum /edge aluminum(20-130mm)

|

|

|

|

|

Material thickness

|

0.6 mm

|

|

|

|

|

Support format

|

AI / PLT / DXF

|

|

|

|

|

Feeding accuracy

|

Length + 0.1mm Radius > 7mm

|

|

|

|

Software

|

Control card

|

Four -axis motion control card

|

|

|

|

|

Software system

|

Auto drive bending system

|

|

|

|

|

Input voltage

|

220V 50Hz 0.8KW

|

|

|

|

|

Air pressure

|

0.6-0.8Mpa

|

|

|

Details Images

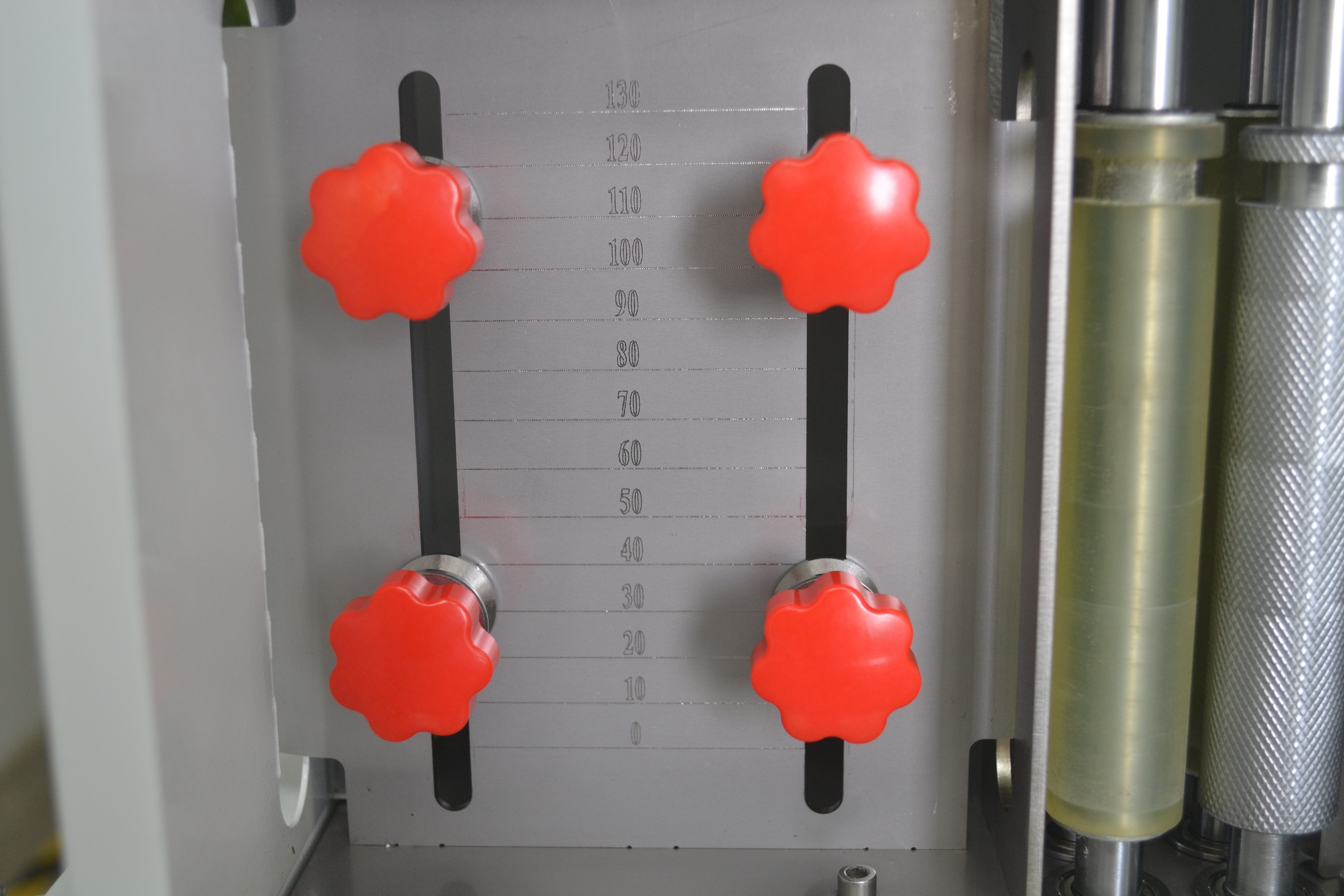

Feeding structure

Material height scale

Encoder

Milling cutter

Slotting structure

Swing structure

Bending structure

IO Board

Machine software

Installation Instructions

https://youtu.be/L6lglAH552A

The video will show you how to install machine parts when you get it.

https://youtu.be/TOKhZqbwXlo

The video will show you how to install machine software drive and operate the software.

P1: Feeding calibration

https://youtu.be/8PWj25qumT0

P2 : Slotting calibration

https://youtu.be/ITQJupCnNeA

P3:Bending calibration

https://youtu.be/c3LYXQOEfNg

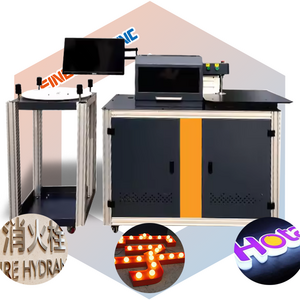

Recommend Products

Hot Searches