- Product Details

- {{item.text}}

Quick Details

-

Keywords:

-

Powder coating, Powder paint

-

Raw material:

-

Epoxy, Polyester, Epoxy polyester

-

Type:

-

Thermosetting

-

Curing:

-

180-200℃,10 min-15 min

-

Particle Size:

-

Average 30-42μm

-

Gloss:

-

High/Low/Matt

-

Special Effect:

-

Chrome/Metallic/Glow in the black/Candy etc.

-

Certificate:

-

ISO9001; SGS; ROHS

-

Texture:

-

Sand/Crocodile/Wrinkle/Hammer etc.

Quick Details

-

CAS No.:

-

Powder Coating Powder

-

Place of Origin:

-

Sichuan, China

-

Colors:

-

Ral, Pantone, or Customized

-

Keywords:

-

Powder coating, Powder paint

-

Raw material:

-

Epoxy, Polyester, Epoxy polyester

-

Type:

-

Thermosetting

-

Curing:

-

180-200℃,10 min-15 min

-

Particle Size:

-

Average 30-42μm

-

Gloss:

-

High/Low/Matt

-

Special Effect:

-

Chrome/Metallic/Glow in the black/Candy etc.

-

Certificate:

-

ISO9001; SGS; ROHS

-

Texture:

-

Sand/Crocodile/Wrinkle/Hammer etc.

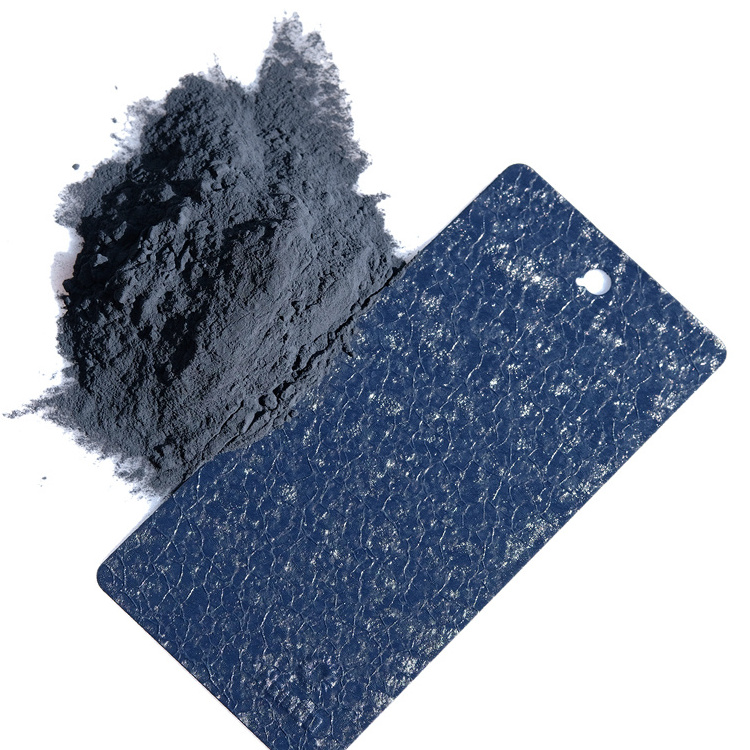

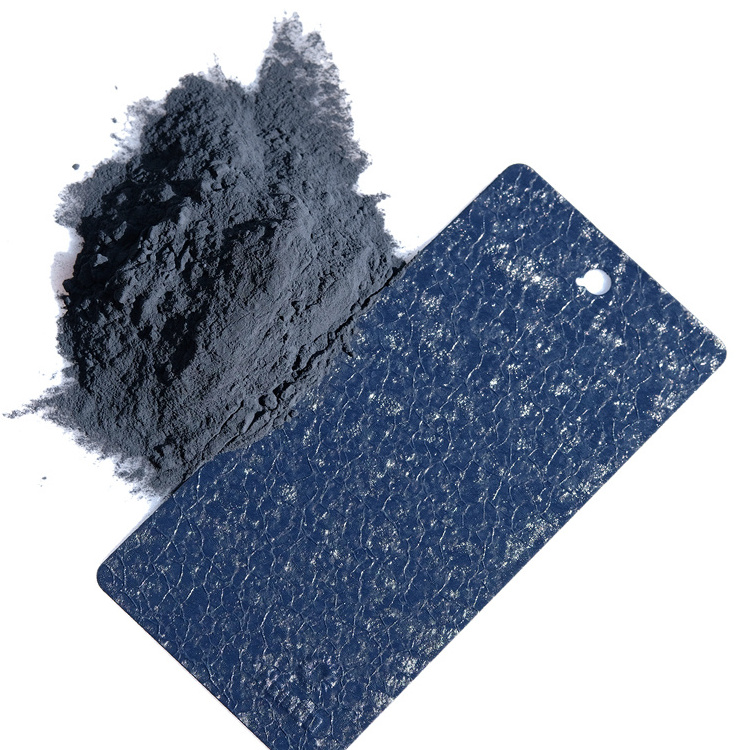

Thermosetting Blue Texture Electrostatic Spray Powder Coating for Metal Surface

1. what is powder coating?

Powder coating is a new type of 100% solid powder coating which does not contain solvents. With no solvent, no pollution, energy and resources saving, recycling, environmental protection, higher performance, low health risk to workforce, economical advantages etc.

Most powder coating is used by electrostatic spraying on metal surface, and then cure in oven, eventually form a solid layer.

2. The main type of Powder Coating

| SORT BY CHEMISTRY | SORT BY FINISH OR CHARACTERISTIC | |

| Epoxy Powder Coating | Excellent Anti-Corrosion | Anti-gassing Powder Coating |

| Excellent chemical resistance | Antimicrobial Powder Coating | |

| High mechanical performance | Crocodile Skin Powder Coating | |

| Recommended for interior | Metallic/Peal Powder Coating | |

| Epoxy-Polyester/Hybrid | Good chemical resistance | Texture Effect Powder Coating |

| Good mechanical property | Wood Effect Powder Coating | |

| Excellent flexibility | Anti-graffiti Powder Coating | |

| Recommended for interior | Chrome Effect Powder Coating | |

| Polyurethane | Excellent anti-corrosion | High Temperature Resistant |

| Excellent flexibility | Sublimation Powder Coating | |

| Excellent smoothness | Transparent Clear Topcoats | |

| Suitable for exterior/interior | Zinc Rich Epoxy Primers | |

| Polyester-TGIC | Excellent UV resistance | |

| Excellent flexibility | ||

| Excellent overbake stability | ||

| Recommended for exterior | ||

| Polyester TGIC-Free | Excellent UV resistance | |

| Excellent flexibility | ||

| Good overbake stability | ||

| Recommended for exterior | ||

3. The application areas of powder coating

| Instrument and apparatus | Spraying on the exterior of instrument and apparatus |

| Architecture | Lock, the reinforcing bar and steel template |

| Furniture utensils | liquefied gas cylinders, cooking utensils of coal gas, tacking off the soot machine |

| Pipeline and valves | antiseptic pipeline, the sending petroleum pipes, the sewage pipe, the water pipe, the gas pipe and valve parties. |

| Electric apparatus | electronic devices and components, the packing of the insulation of coil and electrical machinery rotor. |

| Metal Furniture | Steel furniture, filing cabinet and steel chair |

4. Product Show