- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHONGYOU

-

Voltage:

-

220/380V Optional

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

7.5 T

-

Motor Power (kw):

-

22.5 kw

-

CNC or Not:

-

CNC

-

Power Source:

-

Hydraulic

-

Keyword:

-

fire extinguisher deep drawing machine

-

Application:

-

Deep drawing

-

Servo motor:

-

Nanjing Universal Motor

-

Type:

-

Y32-150T

-

Weight:

-

7.5T

-

Power(W):

-

7.5KW

-

Certification:

-

CE ISO

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Return Force (kN):

-

50 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZHONGYOU

-

Voltage:

-

220/380V Optional

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

7.5 T

-

Motor Power (kw):

-

22.5 kw

-

CNC or Not:

-

CNC

-

Power Source:

-

Hydraulic

-

Keyword:

-

fire extinguisher deep drawing machine

-

Application:

-

Deep drawing

-

Servo motor:

-

Nanjing Universal Motor

-

Type:

-

Y32-150T

-

Weight:

-

7.5T

-

Power(W):

-

7.5KW

-

Certification:

-

CE ISO

Servo System Hydraulic Fire Extinguisher Making Deep Drawing Machine

| Parameter name | Unit | YQ32-63A | YQ32-63B | YQ32-100A | YQ32-100B | YQ32-160 | YQ32-200A |

| Nominal force | KN | 630 | 630 | 1000 | 1000 | 1600 | 2000 |

| Hydraulic system maximum pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 |

| Max opening height of the slide | mm | 500 | 700 | 800 | 800 | 800 | 800 |

| Max stroke of the slide | mm | 360 | 400 | 500 | 500 | 500 | 400 |

| Workbench effective area | mm | 410×450 | 610×500 | 630×550 | 750×700 | 660×600 | 800×800 |

| Ejector cylinder nominal force | KN | 100 | 100 | 200 | 200 | 400 | 400 |

| the stroke of the eject | mm | 160 | 160 | 200 | 200 | 200 | 220 |

| Slider speed | down mm/s | 100 | 100 | 100 | 100 | 100 | 100 |

| press mm/s | 5-10 | 5-10 | 5-10 | 5-15 | 5-10 | 5-10 | |

| return mm/s | 90 | 90 | 90 | 90 | 90 | 90 |

This high-precision cnc servo hydraulic press machine is a servo system hydraulic machine. The advantage of servo hydraulic machine is to save energy saving by 48%, low noise, high stability, precision control, speed control, adjustable control, less heat, lower temperature and temperature rise, and smaller size.

| SERVO SYSTEM VS ORIGNAL SYSTEM | |

| 1. Energy Saving | Compared with the traditional hydraulic machine, the energy saving effect is remarkable. According to the processing technology and the production cycle, the servo drive hydraulic machine can save 30%~70% compared with the traditional hydraulic machine. |

| 2. Less Heat, Low Cost | Because the pump has zero speed and low heat generation for most of the time, the fuel tank of the servo-controlled hydraulic press can be smaller than the traditional hydraulic press tank, and the oil change time can be extended. Therefore, the hydraulic oil consumed by the servo-driven hydraulic press is generally only about 50% of that of the conventional hydraulic press. |

| 3.High Degree Of Automation | The pressure, speed and position of the servo-driven hydraulic press are fully closed-loop digital control, with high degree of automation and remote automatic control. |

1. The system pressure, nominal force, stroke, all could be adjusted in certain range.

2. High speed, high efficiency, low energy, low noise.

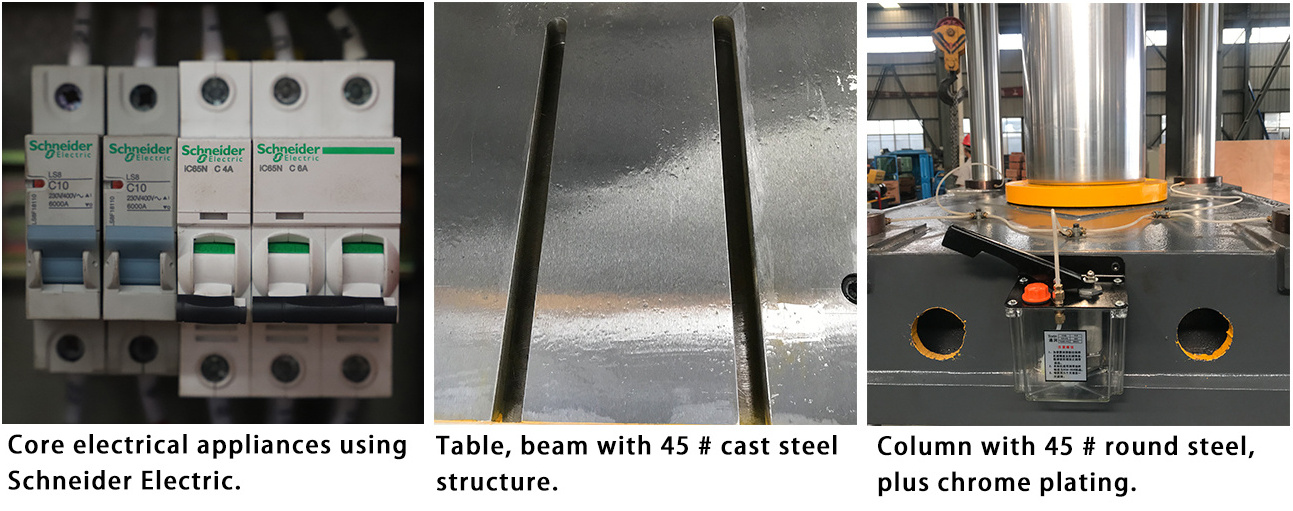

3. Imported hydraulic components and electrical components,durable.

4. Self-seal filter could provide oil pump, maintaining the cleanness of hydraulic oil.

Optional Accessories

1. Electrical safaty protector

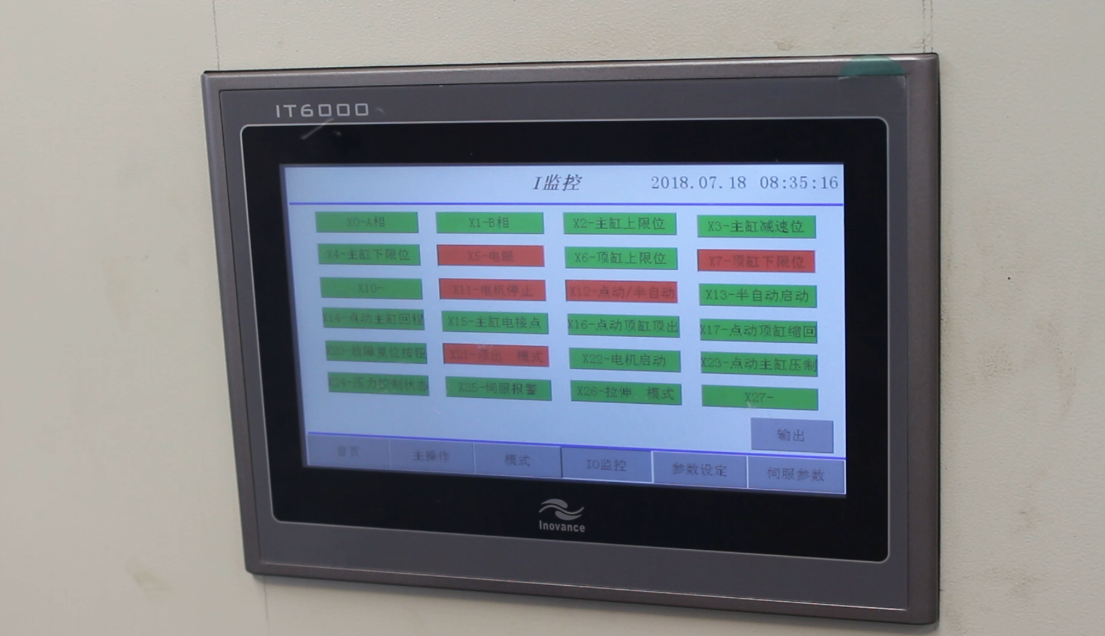

2. PLC

3. Cooling device

4. Slider security check

5. Stroke, pressure, digital display, numerical control device

6. Touch screen

| Accessory | Brand |

| Electromotor | Nanjing Universal Motor Co.,LTD |

| Residual current circuit-breaker | LMKG |

| Hydraulic system | Shandong Taifeng |

| High-pressure Oil Pump | Nanthen Victor High Pressure Oil Pump |

| Electric appliance | DELIXI |

| Seal strip | Imported Metrial |

Details Images

Pre-sale service

1. Inquiry and consulting support.

2. Recommend the most suitable machine according to buyers requirements.

3. Sample testing support.

4. View our Factory.

After-sale service

1. One year warranty.

2. Video or telephone technical support.

3. Training how to instal the machine, training how to use the machine.

4. Engineers available to service machinery overseas.

The customer could use this machine to press pot, water sink, dish end, fire extinguisher, etc.

Deep Drawing

1. Are you manufacturer or trading company?

We are manufacturer and has our own factory, welcome to visit our factory.

The address is: No.219, Xingye North Road, Economic Development Area, Tengzhou, Shandon Province.

2. How to ensure the quality?

We have partners in many countries. The machines have CE, ISO, SGS and other certificates.

3.Whether it is prone to problems?

NO! Electric welding of high precision Usage of high-tech boring machines for extreme precision partsProduction workers have rich experience over the yearsEach of the factory products after repeated testing adjustment.

4.Whether to accept cash on delivery?

Sorry,you have to make a payment as described.

5. How can I choose a suitable machine?

You could send us your requirements about the machine, or the details of the products you want to press(pictures or drawings would be better), I will recommend suitable machine for you.