- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

50M^2

-

Weight:

-

3-4T

-

Function:

-

Remove Water

-

After-sales Service Provided:

-

Training, Online support

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/50Hz

-

Power:

-

28-160KW

-

Dimension(L*W*H):

-

50M^2

-

Weight:

-

3-4T

-

Function:

-

Remove Water

-

After-sales Service Provided:

-

Training, Online support

Waste Tyre Pyrolysis Oil Refinery Machine in India for Oil Distillation Plant

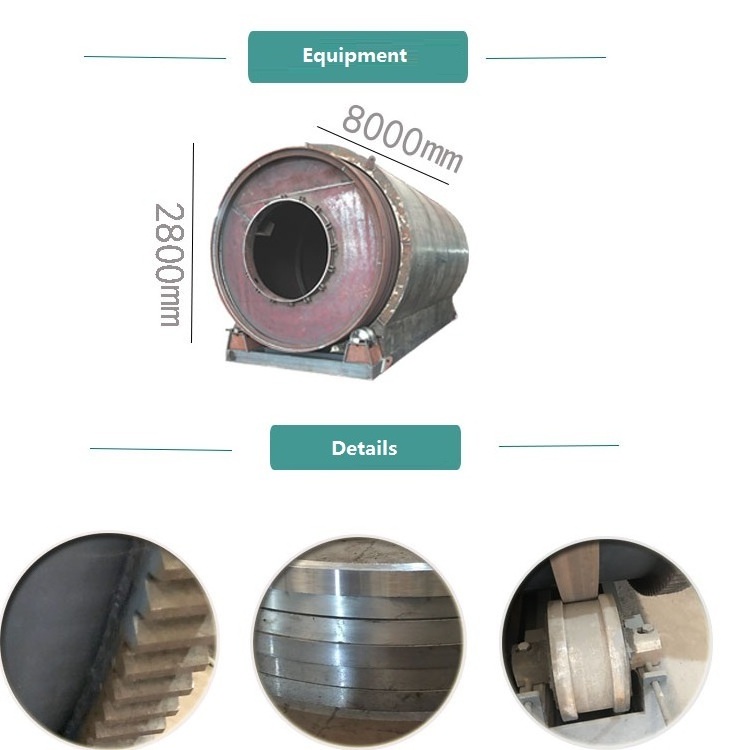

| Dimensions | 2600*6600 2800*6600 2800*800 |

| Suitable for raw materials | waste tire plastic rubber products aluminum plastic oil sludge paint residue waste oil, etc |

| Daily treatment capacity | 1-15 tons |

| Working pressure | atmospheric pressure |

| Engine speed | 0.4 r/m |

| Power | 10-22 KW |

| Weight | 30-45 |

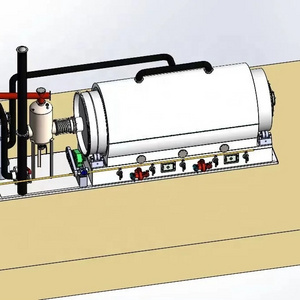

| Structure form | horizontal rotation |

| Material | Q345R |

| After sales | one year warranty and lifelong maintenance |

| Noise | ≤ 85dB |

| Cooling mode | circulating water |

| Fuel | fuel oil, coal and natural gas |

| Installation method | with foundation |

| Transmission mode | external ring gear transmission |

| Working mode | intermittent |

Process flow of refining equipment: (taking waste tire as an example)

1. First, put the waste tire into the reactor from the feed valve, close the feed valve and seal it. The main furnace is heated in the heating room by fuel oil or natural gas.

Buffer room

2. When the temperature reaches 220 ℃, the oil and gas precipitate and enter the buffer chamber, and the residue (including some slag) will sink to the slag tank.

Cooling system

3. Light oil automatically enters the cooling system and condenses into oil

4. Dust removal device:

The dust comes out from the middle of the main furnace and the shell, enters into the flue condensation system, and then enters the dust removal device. The dust removal device filters and purifies the dust. The discharged gas is more than 90% of the water vapor, and it is free of pollution.