Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Working Theory:

-

Electromagnetic Induction Heating

-

Application:

-

Metal forging heating brazing

-

Feature:

-

high efficiency, energy saving, low pricema

-

Model:

-

WXU-100

-

Frequency:

-

10-30KHZ

-

Machine Voltage:

-

3 phase 380V, customize avaliable

-

Max Input Current:

-

157A

-

max temperature:

-

1800c

-

warranty:

-

1 year

-

HS Code:

-

8514400090

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Wangxin

-

Weight (KG):

-

180

-

Working Theory:

-

Electromagnetic Induction Heating

-

Application:

-

Metal forging heating brazing

-

Feature:

-

high efficiency, energy saving, low pricema

-

Model:

-

WXU-100

-

Frequency:

-

10-30KHZ

-

Machine Voltage:

-

3 phase 380V, customize avaliable

-

Max Input Current:

-

157A

-

max temperature:

-

1800c

-

warranty:

-

1 year

-

HS Code:

-

8514400090

Metal Metallurgy Machinery Steel Induction Heating Equipment For Forging

Factors Affecting Heating Efficiency

The efficiency of an induction heating system for a specific application depends on several factors:

1. CHARACTERISTICS OF THE PART ITSELF

A. Metal Or Plastic:

Induction heating works directly only with conductive materials, normally metals.

Plastics and other non-conductive materials can be heated indirectly by first heating a conductive metal susceptor which transfers heat to the non-conductive material.

B. Magnetic or Non-magnetic: It is easier to heat magnetic materials.

C. Thick Or Thin: small or thin parts generally heat more quickly than large thick parts,

Research has shown a relationship between the frequency of the alternating current and the heating depth of penetration: the higher the frequency, the shallower the heating in the part.

D.Resistivity: If you use the exact same induction process to heat two same size pieces of steel and copper, steel heating is much more easier. Steel – along with carbon, tin and tungsten – has high electrical resistivity. Because these metals strongly resist the current flow, heat builds up quickly. Low resistivity metals such as copper, brass and aluminum take longer to heat. Resistivity increases with temperature, so a very hot piece of steel will be more receptive to induction heating than a cold piece.

2. INDUCTION COIL DESIGN

A well-designed inductor provides the proper heating pattern for your part and maximizes the efficiency of the induction heating power supply, while still allowing easy insertion and removal of the part.

B. Magnetic or Non-magnetic: It is easier to heat magnetic materials.

C. Thick Or Thin: small or thin parts generally heat more quickly than large thick parts,

Research has shown a relationship between the frequency of the alternating current and the heating depth of penetration: the higher the frequency, the shallower the heating in the part.

D.Resistivity: If you use the exact same induction process to heat two same size pieces of steel and copper, steel heating is much more easier. Steel – along with carbon, tin and tungsten – has high electrical resistivity. Because these metals strongly resist the current flow, heat builds up quickly. Low resistivity metals such as copper, brass and aluminum take longer to heat. Resistivity increases with temperature, so a very hot piece of steel will be more receptive to induction heating than a cold piece.

2. INDUCTION COIL DESIGN

A well-designed inductor provides the proper heating pattern for your part and maximizes the efficiency of the induction heating power supply, while still allowing easy insertion and removal of the part.

3. CAPACITY OF THE POWER SUPPLY

4. AMOUNT OF TEMPERATURE CHNAGE REQUIRED FOR THE APPLICATION

Machine Show

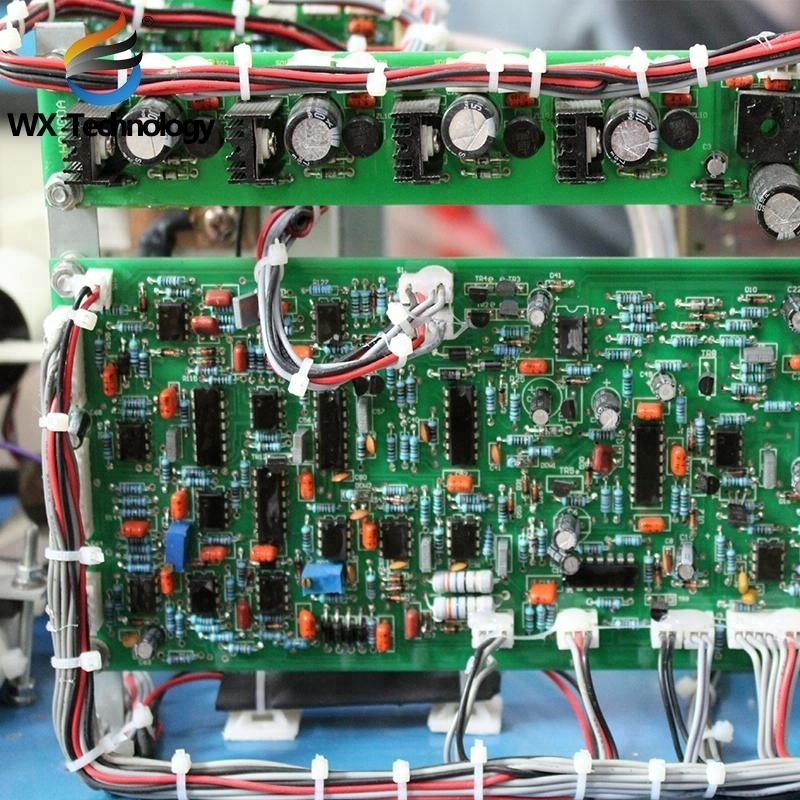

Main Components

Infineon IGBT Module

High Precision PCB Boards

Imported Filter Capacitor

Technical Parameters

|

Model

|

Input Voltage

|

Frequency

|

Max Input Current

|

Water Flow For Cooling

|

|

WXU-30

|

3 phase 380V, 50/60HZ

|

10-40KHZ

|

48A

|

0.2Mpa, 26L/min

|

|

WXU-50

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

63A

|

0.2Mpa, 26L/min

|

|

WXU-65

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

97A

|

0.2Mpa, 32L/min

|

|

WXU-80

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

135A

|

0.2Mpa, 32L/min

|

|

WXU-120

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

195A

|

0.2Mpa, 38L/min

|

|

WXU-160

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

240A

|

0.2Mpa, 38L/min

|

|

WXU-200

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

300A

|

0.2Mpa, 38L/min

|

|

WXU-250

|

3 phase 380V, 50/60HZ

|

10-30KHZ

|

380A

|

0.2Mpa, 38L/min

|

Application

1. Round Square Bar Heating/Hot Forging

2. Steel Strip/ Metal Tube/ Utensil Annealing

3. Gear Shaft Hardening Quenching

4. Copper Tube/ Metal Joint/ Cutting Tools Brazing Welding

Evaluation From Customer

Qatar Customer

Croatia Customer

Bangladesh Customer

Amernia Customer

Finland Customer

Alibaba Customer

Product Package

Packing Details

1. Standard export wooden cases, no need fumigation,

2. Plastic wrap for waterproof,

3. Plastic foam for shockproof,

4. Steel belt for fastening the wooden box corner.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

2. Plastic wrap for waterproof,

3. Plastic foam for shockproof,

4. Steel belt for fastening the wooden box corner.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Process Flow

Wangxin is a really manufacturer for more than 15 years, all manufacturing procedure are finished by ourselves, from raw material purchasing to installation, from coils making to machine commissionning. So we can more easily control the quality and production schedule. What's more, we have our own R&D team and strict QA department, which makes us become stronger and stronger in the competitive market. Come on, dear! Wangxin will satisfy you all.

Service

1. One year warranty time and 24 hours online service

2. Within one year free warranty, any fault caused by non-artificial reason, any quality problem like design, manufacture or procedure occurs, Wangxin would provide free replacement parts.

3. Large inventory of spare parts ready for immediate delivery.

4. Customized design and induction heating solutions.

5. Welcome your engineers to come to factory accept maintenance training & trouble shooting guide.

2. Within one year free warranty, any fault caused by non-artificial reason, any quality problem like design, manufacture or procedure occurs, Wangxin would provide free replacement parts.

3. Large inventory of spare parts ready for immediate delivery.

4. Customized design and induction heating solutions.

5. Welcome your engineers to come to factory accept maintenance training & trouble shooting guide.

Famous Enterprise We Service

Certifications

Hot Searches