- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

2 - 10

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HONJIA

-

Voltage:

-

220V/380V/415V

-

Rated Power:

-

~165KW

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

400000

-

Year:

-

NEW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SS,CR,HR,GI,AL,Copper,Special steel etc.

-

Speed:

-

50m/min

-

Coil thickness:

-

0.3-2.0mm

-

Width:

-

500-1400mm

-

Coil max weight:

-

15T

-

Coil ID:

-

508/610mm

-

Coil OD:

-

≤1500mm

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO 9001

Quick Details

-

Cutting Width (mm):

-

500 - 1400 mm

-

Material Thickness(mm):

-

0.2 - 2 mm

-

Cutting Speed(m/min):

-

10 - 50 mm

-

No. of Slitting Lines:

-

2 - 10

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HONJIA

-

Voltage:

-

220V/380V/415V

-

Rated Power:

-

~165KW

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

400000

-

Year:

-

NEW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SS,CR,HR,GI,AL,Copper,Special steel etc.

-

Speed:

-

50m/min

-

Coil thickness:

-

0.3-2.0mm

-

Width:

-

500-1400mm

-

Coil max weight:

-

15T

-

Coil ID:

-

508/610mm

-

Coil OD:

-

≤1500mm

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO 9001

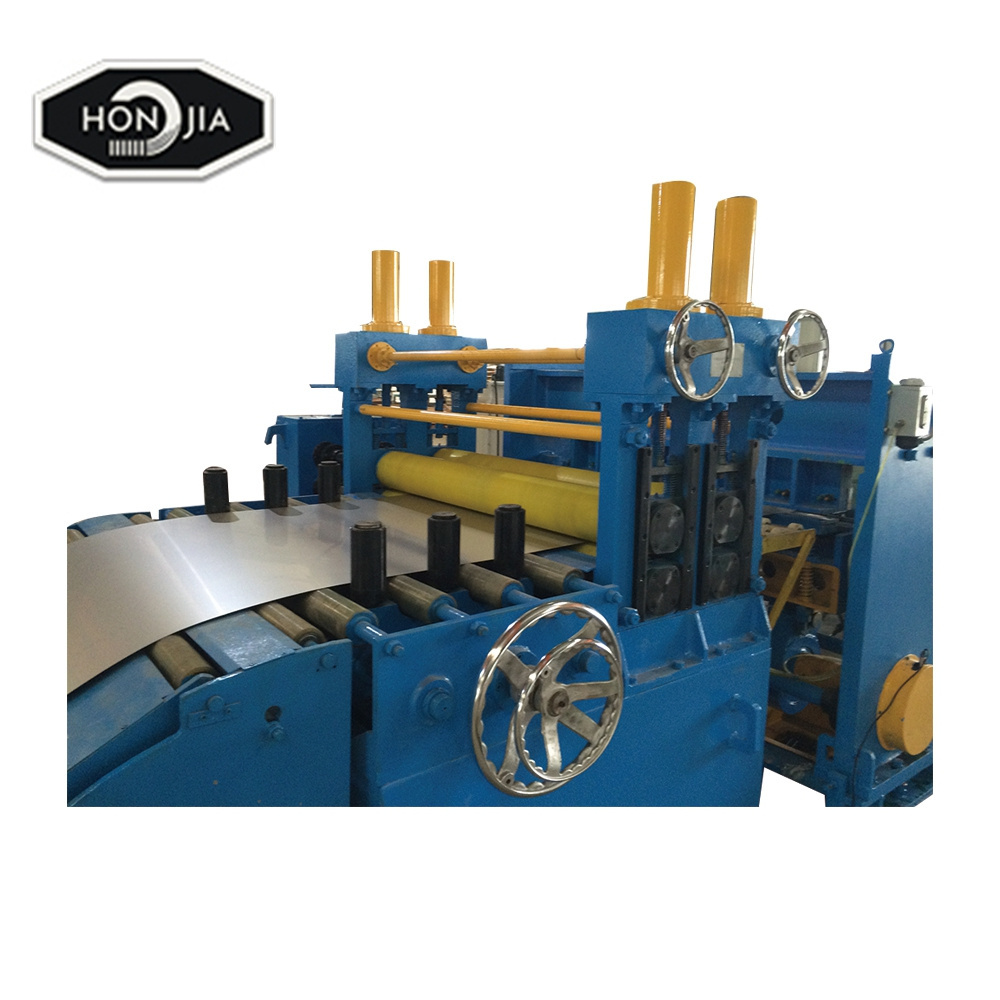

| Information |

| Material | SS,CR,HR,GI,AL,Copper etc. | Coil ID | Φ508/610 |

| Coil width | 500-1400mm | Coil OD | ≤Φ1500 |

| Coil max weight | 15T | Length arrarge | 500-3500 |

| Power | 95kw | Flatness | ≤1.5 |

| Speed | 50m/min | Length accuracy | ≤±0.5 |

| Thickness | 0.3-2.0mm | Floor space | 22*7m |

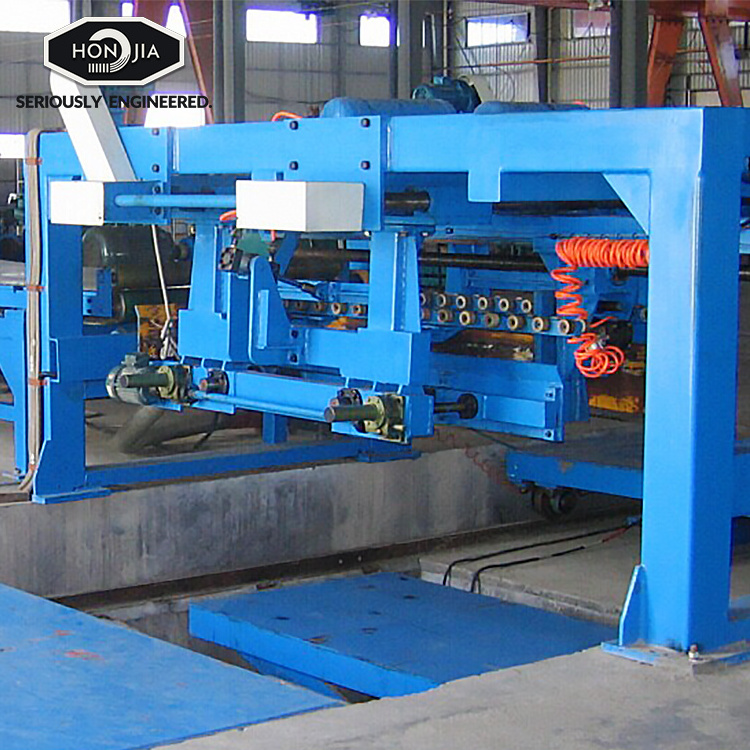

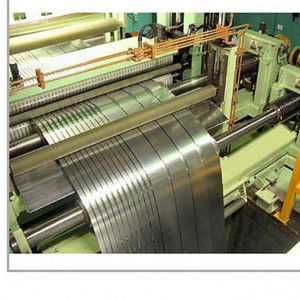

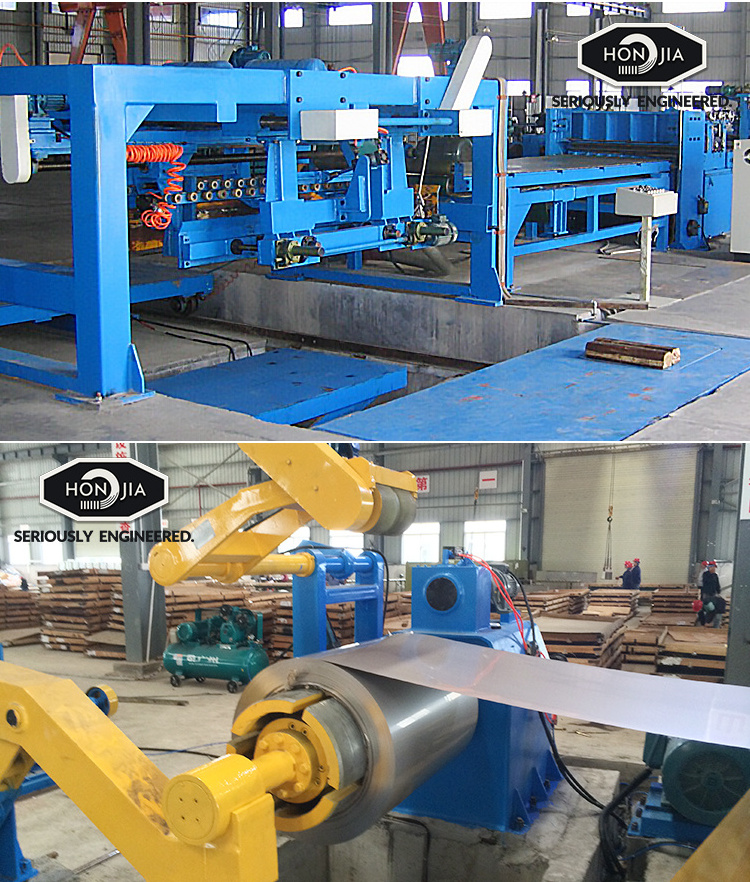

| Display |

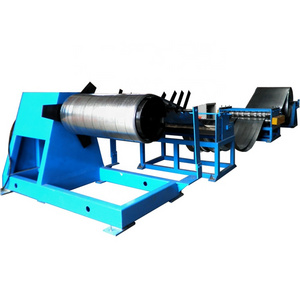

steel coil cut to length machine is widely used for auto parts, annealing, metal sheet, automobile parts, metal case, metal punching, package steel strips industries, Etc. Our steel coil cut to length machine has been exported more than 50 countries, also win good reputation from our customers, and we will be stronger and have a good team for design and development. We always win with our qualified quality, and to cooperate with you is our biggest honor.

| Item |

|

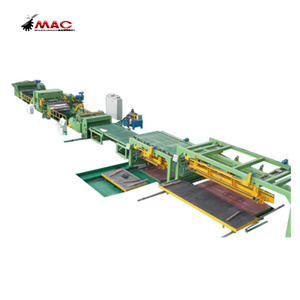

1 . Paper collector 2 . S upport arm 3 . Loading coil car 4 . Decoiler 5 . 19-roller leveler 6 . Loop pit and bridge 7 . Guardrail 8 . NC length 9 . Cross shear 10 . Conveyor belt 11 . Stacking device 12 . L i fting table 13 . Unloading roller 14 . Hydraulic/pneumatic/lubrication system 15 . Electrical cabinet |

More Products

| Model | Coil width (mm) | Coil max weight (T) | Power (kw) | Speed (m/min) | Thickness (mm) | Floor space (m) |

| 0.3~2x1400 | 500-1400 | 15 | 95 | 180 | 0.2-2.0 | 11*4 |

| 0.3~3x1700 | 500-1700 | 20 | 90 | 180 | 0.2-2.0 | 11*4 |

| 1~6x1800 | 600-1800 | 30 | 155 | 180 | 0.2-2.0 | 11*5 |

| 0.3~3x1600 | 500-1600 | 20 | 90 | 180 | 0.15-2.0 | 12*6 |

|

Our Company |

|

Our Advantages |

| Packaging |

| Contact Us |

| Tel | +86-757-8108 1122 |

| Mobile | +86-13929919722 |

| Fax | +86-757-8108 1116 |

| honjiamachine @ gmail.com | |

| web | www.honjia-machine.com |

| Address |

#1, Hongying Industrial Zone, Tangtou, Shishan Town, Foshan, Guangdong, China (Mainland) |

| FAQ |

|

Q1:How much is your machine? A1:Sorry, we cannot answer this question before understanding your exact demand and re- quirements. For example, if you ask: “how much is an APPLE iPhone?” It’s impossible for any salesman to answer. Basically we have to tell them exact model 3/4/5/6/7/8/X or plus, 32/64/128/256G, etc.

Q2:How can I know the design and proposal of the machine line? A2:Generally speaking, we need to know: (1)Machine type: slitting line or cut to length line (normal CTL or flying CTL) . (2)Raw material info: such as thickness/width/master coil weight/coil ID/coil OD. (3)Final product info: such as slit nos (at thinnest and thickest)/min. strip width/precision and tolerance/exit coil ID, etc. such as target length to cut, length tolerance, diagonal tolerance, etc. 4)Line speed: normal type or high speed type 5)Line type: normal type or compact design (for example, same function with single loop or double loops) 6)Electrical system: China mainland/Taiwan/Japan/European brands 7)Optional functions: such as paper collector/film coating/burr masher/digital display/special loading and unloading designs, etc.

Q3:How long will you send the proposal and offer? A3:We will need about 3~7 days to design the proposal upon collecting all details of the ab- ove mentioned info necessary.

Q4:When will you tell me the price? A4:After confirming all detailed configurations of the machine line, that we are able to make offer for it.

Q5:How long do you need to produce the machine? A5:We need about 3 months to produce light gauges; about 4~5 months to produce the me- dium gauges; 6~10 months to produce heavy gauges.

Q6:What pricing terms to you accept? A6:We accept 30% TT as deposit and 70% TT before delivery. 30% TT as deposit and 70% LC terms is also considerable.

Q7:How long do you need to install and commissioning the machine line? A7:Light gauges, we need about 10~14 days; Medium gauges, we need about 28 days; He- avy gauges, we need about 1~2 months.

Q8:How many people will come to install and commission the machine line? A8:Light gauges, we will send 1 engineer, with the assistance of your stuff in your workshop. Medium/heavy gauges, we will send 2~3 engineers, with the assistance of your stuff in your workshop.

Q9:Do I need to pay extra charge for installation and commissioning? A9:We are not charging extra fee for it, but the buyer is responsible for the round trip tickets/ visa/local transportation/hotels of our technicians as well as USD50/day/person allowance only.

Q10:What about the warranty of your machine? A10:We offer 1 year warranty for our machine lines starting from the acceptance date of ins- tallation and commissioning.

Q11:How long do you need to prepare the foundation drawings for the machine line? A11:Upon receipt of 30% deposit, we need about 30~45 days to prepare the foundation drawings for you. |