- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.1kw

-

Weight:

-

550 kg

-

Dimension(L*W*H):

-

700*500*800mm

-

Product Name:

-

Foodgrade stainless juice filter press for apple juice and syrups

-

Model:

-

DZCR300-10

-

Function:

-

Filtration and separation

-

Material of filter plate:

-

304 or 316L stainless steel

-

Material of frame:

-

304 or 316L stainless steel

-

Layer:

-

10PCS

-

Filter area(m2):

-

0.7

-

Filtration pressure(MPa):

-

0.15

-

Water flow(t/h):

-

4

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Toper

-

Voltage:

-

380V, Optional

-

Power:

-

1.1kw

-

Weight:

-

550 kg

-

Dimension(L*W*H):

-

700*500*800mm

-

Product Name:

-

Foodgrade stainless juice filter press for apple juice and syrups

-

Model:

-

DZCR300-10

-

Function:

-

Filtration and separation

-

Material of filter plate:

-

304 or 316L stainless steel

-

Material of frame:

-

304 or 316L stainless steel

-

Layer:

-

10PCS

-

Filter area(m2):

-

0.7

-

Filtration pressure(MPa):

-

0.15

-

Water flow(t/h):

-

4

-

After-sales Service Provided:

-

Online support

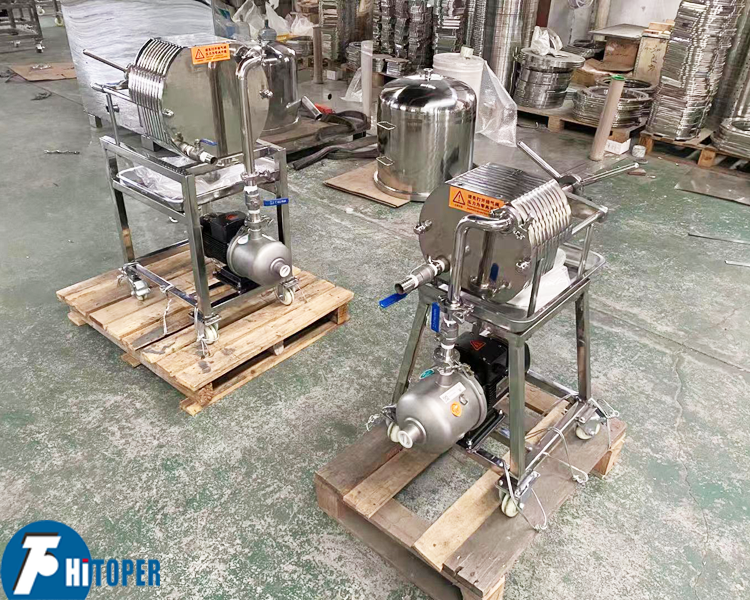

Food grade stainless juice filter press for apple juice and syrups

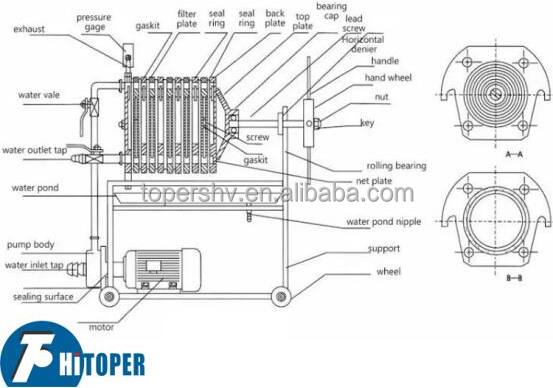

The multi-layer stainless steel frame filter is a filter used for filtration of various suspending liquid. The machine is made of SUS304 or SUS316L stainless steel. It’s durable and corrosion-resistant. Filter plate is of thread-like structure. This machine can be used according to the different production processes (initial filter, semi-fine filter, fine filter) of the filtered liquid. A sterile filtrate can be generated by direct use of sterile filtration membrane. Users can replace different filter media according to the production flow rate. Users can increase or reduce the quantity of layers as per filter flow capacity. When working, the filter is in the state of sealing and pressure, without loss of liquid material, liquid clarity is good. It’s suitable for separating suspensions with low viscosity and slagging content under the concentration of 50%.

In operation, the suspension goes into the filter room with the help of a pump. Due to the pressure, the filtrate passes through the filter payer and the membrane, and is finally discharged from the outlet. Residues are formed by plate and frame, and kept in the room, so as to achieve the goal of solid-liquid separation.

l

Automatic liquid-return device.

When the pump stops and the return valve is opened, all sediments are discharged automatically and clean water is brought in from the recoil pipe to wash the equipment.

l

Explosion-proof motor.

Explosion proof motors are required for industrial applications with the presence of highly combustible, pervasive materials. Explosion proof does not mean that the motor will never explode, nor that it is immune from external explosions. Rather, an explosion proof motor has features that prevent an internal motor explosion from igniting a larger, ambient, combustible atmosphere.

l

High pressure reinforced polypropylene (PP) filter plate.

This type of frame filter is made with high quality 304 or 316L stainless steel. However the plate material can be replaced with our reinforced PP plate, which is acid-proof, corrosion resistant, odorless, and much cheaper.

|

l

Single bag filter.

Filter bag is supported by the metal basket inside filter, and liquid flows into the inlet, filtered through the bag out from the outlet, impurities are kept in the bag. Replace the filter bag and then continue to use. |

|

|

l

Multi-bag filter.

Multi-bag filter is for high flow filter. From 2-24 bags. Equipped with the fast open design, filter bag replacement is very convenient. It is of large processing capacity and small size. |

|

|

l

Diatomite filter

Manufactured with 1Cr8Ni9Ti high quality stainless steel and uses the diatomaceous earth as the filter aid. Widely used in white wine, red wine, yellow wine, fruit juice, water treatment, etc. |

Solid-liquid separation in industries such as:

l Mining.

l Metallurgy.

l Petroleum.

l Chemical.

l Textile.

l Printing and dyeing.

l Paper making.

l Food and beverage processing.

l Inorganic salt.

l Coal washing.

l Ceramics.

l Leather.

l Biological.

l Sewage treatment industries.

l Environmental protection unit, etc.

This machine is widely used in wine, fruit juice, oil, beer and other food and beverage processing.

Company

Zhengzhou Toper is the leading suppiler of industrial equipment in China, and also the professional exporter and service provider of filter and separation equipment. We focus on full service for filtering project from design to after-sales service and fast supply of spare parts.

All products of Toper:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compress filter press

4. Mechanical compress filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Round plate filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY rotary drum thickening/dehydrating belt filter press

14. Triple-belt thickening and dehydrating filter press

15. SS type three-foot upper discharge centrifuge

16. SD type three-foot and filter bag hoist discharge centrifuge

17. PD type filter bag hoist discharge centrifuge

18. Centrifuge of up discharge, three foot, clean series SSB, SB

19. SX type manual top discharge centrifuge

20. PS type manual top discharge centrifuge

21. SGZ type automatic scraper bottom discharge centrifuge

22. PGZ type scraper bottom discharge centrifuge

23. LW series decanter centrifuge

24. Tubular centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomite filter

28. Filter plate

29. Filter cloth

30. Vacuum disc filter

Order notice

1 All of our products are provided without a pump and pipes. To order a complete unit, please state it in the contract.

2 Products can be customized by changing colors and materials, altering the size, or adding logos, to meet your special demands. We use materials and components from market leaders and well-known manufacturers.

3 It can be designed and manufactured as per GMP specifications.

Shipping

Contact us