Siemens human-machine operation interface, simple operation and high degree of automation.

Intelligent regulation of energy usage to optimize energy consumption.

Collect and record various data in the production process in real time, and through data analysis, help production managers optimize the production process, improve production efficiency, and perform fault diagnosis and prediction.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MAIWEI

-

Year:

-

new

-

Dimension(L*W*H):

-

250x160x200

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

50 mm

-

Screw Heating Power(kW):

-

4 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

100 mm

-

Mold Platen Size(Height)(mm):

-

280 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

3 kW

-

Accumulator Capacity(L):

-

1 L

-

Power (kW):

-

37

-

Weight (T):

-

2.5

-

Model Number:

-

MW-2S1L

-

Product name:

-

Extrusion Blow Molding Machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

After-sales Service Provided:

-

Online Support

-

Suitable bottle:

-

1L 2L 5L Bottle

-

Bottle material:

-

PP PE PET PVC

-

Advantage:

-

Famous brand motor

-

Key words:

-

Extrusion Blow Molding Machine

-

Mould stroke:

-

148-508mm

-

Type:

-

Extrusion Blow Molding Equipment

Quick Details

-

Clamping Force (kN):

-

20

-

Output (kg/h):

-

35 kg/h

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MAIWEI

-

Year:

-

new

-

Dimension(L*W*H):

-

250x160x200

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

50 mm

-

Screw Heating Power(kW):

-

4 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

100 mm

-

Mold Platen Size(Height)(mm):

-

280 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

3 kW

-

Accumulator Capacity(L):

-

1 L

-

Power (kW):

-

37

-

Weight (T):

-

2.5

-

Model Number:

-

MW-2S1L

-

Product name:

-

Extrusion Blow Molding Machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

After-sales Service Provided:

-

Online Support

-

Suitable bottle:

-

1L 2L 5L Bottle

-

Bottle material:

-

PP PE PET PVC

-

Advantage:

-

Famous brand motor

-

Key words:

-

Extrusion Blow Molding Machine

-

Mould stroke:

-

148-508mm

-

Type:

-

Extrusion Blow Molding Equipment

Overview

video description

Products Description

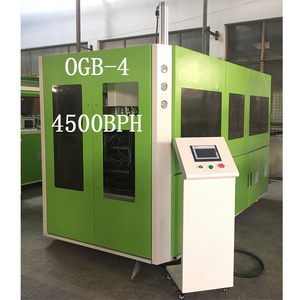

Automatic Extrusion Blow Molding Machine

The fully automatic hollow blow molding machine is an advanced equipment used to produce hollow plastic products. It is widely used in food packaging, cosmetic bottles, pharmaceutical containers, industrial pipes and other fields.

Features:

*

Both single die heads and multi-die heads have center feed and side feed. Each die head has a dedicated flow divider. The flow rate and pressure of each flow channel can be adjusted, and each die head can be matched with Used with wall thickness control system.

*

Suitable for the production of plastic hollow products made of PE, PP, EVA, ABS, K material, TPU, nylon and other materials below 12 liters.

*

The three-guide-pillar balanced pull-push rod structure, bottom-loading super-hard quenched and tempered guide pillars and fully open template design can accommodate over-long and over-wide molds.

Product Paramenters

|

Model No

|

Unit

|

MW-2S1L

|

MW-2S2L

|

MW-2S3L

|

MW-2S5L

|

MW-2S12L

|

|

Max product volume

|

L

|

0.5

|

2

|

3

|

5

|

12L/1;5L/2

|

|

Dry Cycle

|

pc/h

|

950x2

|

800x2

|

600x2

|

700x2

|

600X2

|

|

Screw Diameter

|

mm

|

50

|

60

|

70

|

70

|

90

|

|

Screw L/D Ration

|

L/D

|

25

|

25

|

25

|

25

|

25

|

|

Screw Motor Power

|

KW

|

11

|

11

|

22

|

22

|

37

|

|

Screw Heating Capacity

|

L

|

2.5-4

|

4.8-7.5

|

5-6.7

|

5-6.7

|

7.3-9

|

|

No.of Heating Zone

|

Zone

|

3

|

3

|

3

|

3

|

4

|

|

Output of HDPE

|

kg/hr

|

30-35

|

50-60

|

70-85

|

70-85

|

120-150

|

|

Oil Pump Driver Power

|

kw

|

5.5

|

7.5

|

11

|

11

|

15

|

|

Clamping Force

|

kn

|

20

|

38

|

80

|

68

|

110

|

|

Mold Stroke

|

mm

|

100-250

|

138-368

|

135-360

|

148-508

|

180-600

|

|

Size of Mold(W*H)

|

mm

|

100x280

|

300x320

|

250x430

|

370x390

|

500X510

|

|

Moving Distance

|

mm

|

310

|

370

|

520

|

420

|

550

|

|

Max.Die Diameter

|

mm

|

35

|

90

|

90

|

160

|

220

|

|

Die Heat Capacity

|

kw

|

1.5-3

|

1.8-3.5

|

3.5-4.3

|

3.5-4.3

|

4.5-5.5

|

|

Blowing Pressure

|

Mpa

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

|

Air Volume

|

Min

|

0.3

|

0.4

|

0.8

|

0.6

|

0.8

|

|

Cooling Water Pressure

|

Mpa

|

0.3

|

0.3

|

0.4

|

0.4

|

0.5

|

|

Water Consumption

|

L/min

|

40

|

50

|

60

|

60

|

70

|

|

Weight of Machine

|

Ton

|

2.5

|

4.5

|

4.8

|

6

|

11.2

|

|

Size of Machine(LXWXH)

|

m

|

2.5x1.6x2

|

3x2x2.1

|

3.5x2.1x2.1

|

3.5x2.1x2.1

|

3.5X3.5X2.6

|

Machine Parts

Control System

Electrical System

The electrical system includes a series of electrical components, sensors, actuators, controllers, etc., used to realize automation and precise control of the entire blow molding process.

Maiwei stretch blow molding machines use imported electrical components such as Siemens and Schneider, which have a long service life.

Professional industrial fans are embedded in the electrical cabinet to ensure stable operation of electrical equipment in a variety of environments.

Extrusion System

.

The extrusion system of the stretch blow molding machine consists of a screw extruder, heating system, die head, pressure control system, cooling system, drive system, and automation control system.

The inside of the die head is finely processed using a machining center imported from Japan, and the die head can move forward and backward.

The storage tank type die head is made of high-quality materials and has a longer service life.

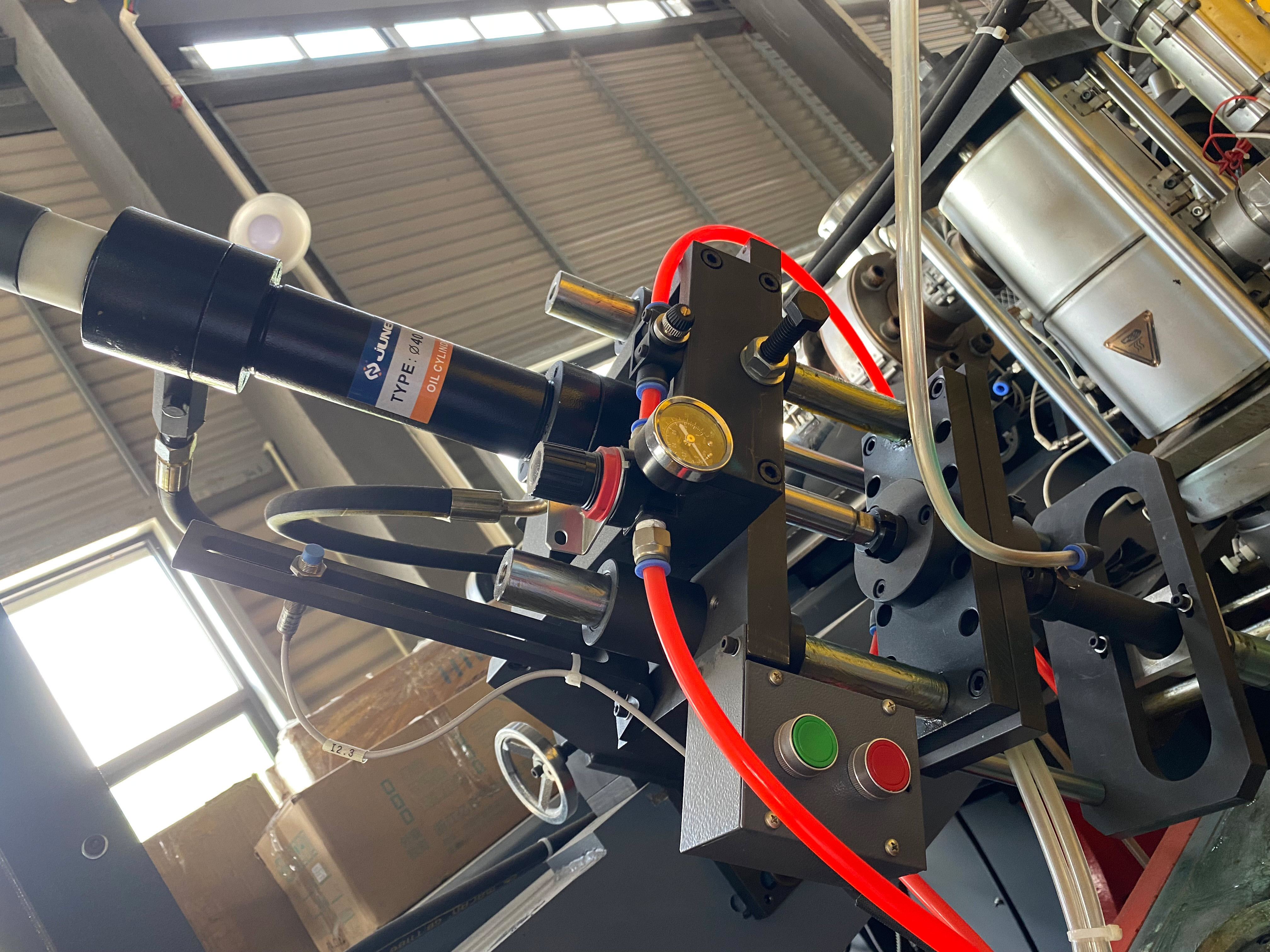

Hydrulic System

Hydraulic system is a system that uses liquid (usually oil) to transfer energy and is widely used in various engineering and mechanical fields. This system uses pressure to transfer fluids to perform various mechanical tasks such as lifting, compressing, bending, rotating, etc. Maiwei's dialysate barrel extrusion blowing machine uses Japanese Yuken hydraulic valves and imported seals as well as servo control, which enables the blow molding machine to achieve high-precision, high-efficiency and reliable hydraulic system performance.

Packing and Shipping

Packaging:

Stable wooden packaging protects the machine from impact and damage.

A wrapped plastic film protects the machine from moisture and corrosion.

This is a fumigation-free package that supports smooth customs clearance.

Large machines are fixed in containers without packaging.

Shipping:

At LCL, we worked with a reliable logistics team to get the machine to the port quickly and safely.

At FCL, we obtain containers, and our skilled workers carefully load the containers.

As for forwarders, we have professional and long-term cooperation forwarders who can process your shipments smoothly. We also want to achieve seamless cooperation with forwarders at your convenience.

Customization Service

We will provide the best process plan based on your product and provide a complete set of mold designs to ensure that the bottle cap (injection mold) and bottle body (blow mold) match flawlessly.

Use high-precision machining centers to process high-precision molds

* Excellent cooling effect

* Provide free proofing service

*Exquisite production technology

*Strict quality requirements

Hot Searches