- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SHUIWANG

-

Model Number:

-

S

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

25 hp-3300 hp

-

Cable Length:

-

According to customer requirements

-

Outlet Size:

-

150 mm-1400 mm

-

Power:

-

18.5 kw-2500 kw, Electric

-

Theory:

-

Centrifugal Pump

-

Usage:

-

Water

-

Product name:

-

Stainless Steel Centrifugal Large Power Silent Suction Water Pump 15hp

-

Material:

-

Cast Iron

-

Name:

-

Centrifugal Large Power Silent Suction Water Pump 15hp

-

Motor:

-

100% Copper Wire

-

Feature:

-

High Efficiency

-

Fuel:

-

Electric water pump

Quick Details

-

Application:

-

Automotive Industry, Biofuel Industry, Commercial Buildings, Developing World Water Solutions, District Energy, Drinking water treatment, Family Homes, Food and Beverage Industry, HVAC OEM, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Raw Water Intake, temperature control, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions

-

Voltage:

-

380V/415V/660V/1140V

-

Warranty:

-

one year, 1 Year

-

Brand Name:

-

SHUIWANG

-

Model Number:

-

S

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

25 hp-3300 hp

-

Cable Length:

-

According to customer requirements

-

Outlet Size:

-

150 mm-1400 mm

-

Power:

-

18.5 kw-2500 kw, Electric

-

Theory:

-

Centrifugal Pump

-

Usage:

-

Water

-

Product name:

-

Stainless Steel Centrifugal Large Power Silent Suction Water Pump 15hp

-

Material:

-

Cast Iron

-

Name:

-

Centrifugal Large Power Silent Suction Water Pump 15hp

-

Motor:

-

100% Copper Wire

-

Feature:

-

High Efficiency

-

Fuel:

-

Electric water pump

|

|

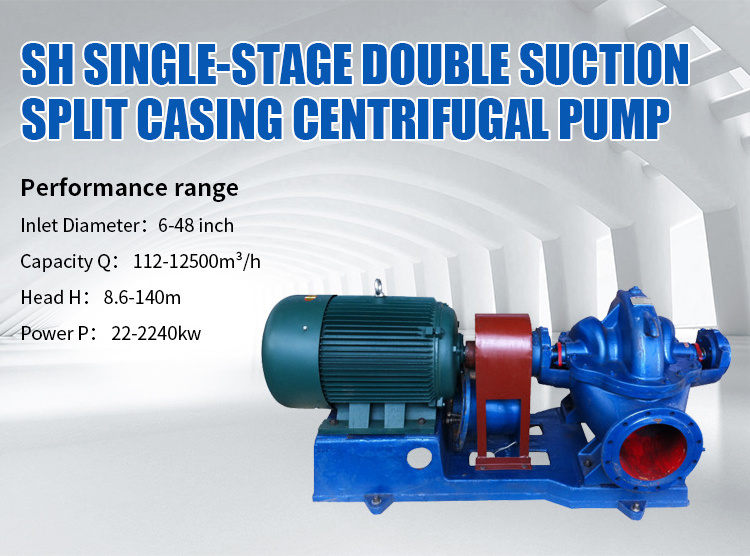

Specification

|

|

|

|

Inlet Diameter

|

6-48inch

|

|

|

|

Capacity Q

|

112-12500m

3

/h

|

|

|

|

Head H

|

8.6-140m

|

|

|

|

Power P

|

22-2240KW

|

|

|

|

Motor

|

Brand optional,100% Copper Wire

|

|

|

|

Voltage

|

380V/415V/660V/1140V

|

|

|

|

Material

|

Cast Iron/SS316/SS304/Copper,Can be customized

|

|

|

|

Scope of supply

|

Pump,Motor,Coupling,Base,Pipe,Control cabinet,Flange,Wearing parts,Other Accessories

|

|

|

|

Certification

|

ISO 9001

|

|

|

|

Warranty

|

One Year/According to customer requirements

|

|

|

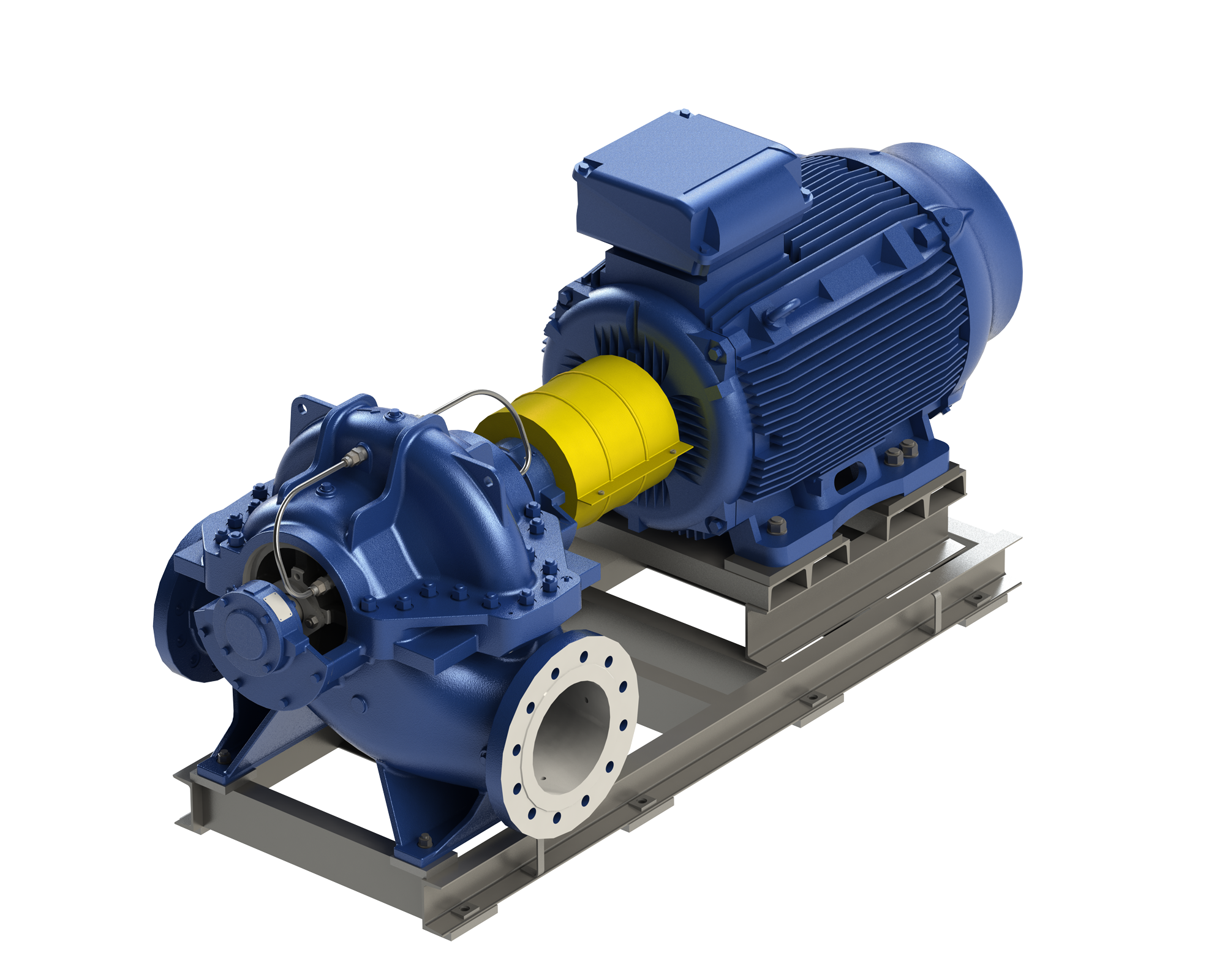

The SH type is a single stage double suction split case centrifugal pump, suitable for conveying clean water and non-corrosive (or weakly corrosive) liquids.The maximum temperature of the medium is 80 degrees. After the bearing bodies at both ends pass through the cooling water,hot water of not more than 130 degrees can be delivered. According to the customers’ special requirements,the material can be changed to meet other conditions of use.

Single stage irrigation double suction split case centrifugal water pump

.Mainly used in water supply plants, air conditioning circulating water,heating network systems, building water supply, irrigation, drainage pumping stations, power plants, industrial water supply systems, fire protection systems, shipbuilding industry, mine water supply and drainage, etc.

The pumps mean that:For example 10SH-13A

10-------Pump’suction diameter is divides by 25(i.e.the suction diameter is 250mm)

SH--------Single stage double suction centrifugal pump

13 ------The specific speed is divides by 10(i.e.this pump specific speed is 130)

A --------Pump impeller is cutted for the first time

10-------Pump’suction diameter is divides by 25(i.e.the suction diameter is 250mm)

SH--------Single stage double suction centrifugal pump

13 ------The specific speed is divides by 10(i.e.this pump specific speed is 130)

A --------Pump impeller is cutted for the first time

Single stage irrigation double suction split case centrifugal water pump.

The main components of the pump are pump body, pump cover, impeller, shaft, double suction seal ring, shaft sleeve and bearing body.

1) The pump body and the pump cover are made of cast iron, which together form the working chamber of the impeller. There are pipe screw holes for the pressure gauge and vacuum gauge on the inlet and outlet flanges of the pump body. At the lowest point of the pipe diameter, there is a pipe screw hole for discharging water.

2) Double-side inflow impeller,its shape is symmetrical, and it is tested by static balance at the factory.

3) Bearing: The structure of this series of pumps adopts rolling bearing (caliber 150mm-500mm) and is lubricated with butter.

4) Shaft seal: The shaft seal of the pump is composed of packing chamber, packing ring, packing gland, packing sleeve, packing and shaft sleeve.

5) Pump with caliber ≥350, water filter is mounted at the end of the suction pipe.Before start up the pump,use a vacuum pump to draw the water. Therefore, two sets of exhaust pipes are installed in the upper part of the pump cover, and a small check valve is connected in series in the pipe. A small check valve is used to prevent high pressure water from flowing back into the low pressure zone during normal pump operation.

1) The pump body and the pump cover are made of cast iron, which together form the working chamber of the impeller. There are pipe screw holes for the pressure gauge and vacuum gauge on the inlet and outlet flanges of the pump body. At the lowest point of the pipe diameter, there is a pipe screw hole for discharging water.

2) Double-side inflow impeller,its shape is symmetrical, and it is tested by static balance at the factory.

3) Bearing: The structure of this series of pumps adopts rolling bearing (caliber 150mm-500mm) and is lubricated with butter.

4) Shaft seal: The shaft seal of the pump is composed of packing chamber, packing ring, packing gland, packing sleeve, packing and shaft sleeve.

5) Pump with caliber ≥350, water filter is mounted at the end of the suction pipe.Before start up the pump,use a vacuum pump to draw the water. Therefore, two sets of exhaust pipes are installed in the upper part of the pump cover, and a small check valve is connected in series in the pipe. A small check valve is used to prevent high pressure water from flowing back into the low pressure zone during normal pump operation.

|

Model

|

Inlet/Outlet(inch)

|

Capacity(m3/h)

|

Head(m)

|

Power(KW)

|

Speed(rpm)

|

|

6SH

|

6

|

112-220

|

35-84

|

30-55

|

2900

|

|

8SH

|

8

|

160-351

|

31-100

|

37-110

|

2900

|

|

10SH

|

10

|

320-612

|

8.6-71

|

22-132

|

1450

|

|

12SH

|

12

|

504-972

|

10-98

|

30-300

|

1450

|

|

14SH

|

14

|

745-1663

|

10-140

|

55-680

|

1450/1470

|

|

16SH

|

16

|

800-1620

|

30-97

|

110-630

|

980/1480

|

|

20SH

|

20

|

1150-2450

|

10-108

|

110-800

|

970

|

|

24SH

|

24

|

2340-3960

|

13-80

|

185-900

|

960/970

|

|

32SH

|

32

|

4680-9900

|

25.4-73.5

|

560-2240

|

590/730/742

|

|

48SH

|

48

|

8500-12500

|

14.3-28.5

|

800-1250

|

800/1250

|

Hot Searches