- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HR-NI718-P

-

Shape:

-

powder

-

Material:

-

Nickle,chrome.molybdenum,niobium

-

Chemical Composition:

-

Ni.Cr.Mo.Nb

-

Product name:

-

SLS Metal Powder Inco Nickel Alloy 718 Inconel 718 Powder

-

Color::

-

Gray

-

Application::

-

3D printing Industry, 3D printing metal powder

-

Shape::

-

spherical

-

purity::

-

99.9%

-

Features::

-

fatigue and creep-rupture

-

Density::

-

0.296 lb/in3 annealed

-

Melting Range::

-

2410 - 2540°F

-

Hardness, Rockwell:

-

42-44

-

Temperature::

-

-423° to 1300°F

Quick Details

-

Application:

-

3D printing

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

HUARUI

-

Model Number:

-

HR-NI718-P

-

Shape:

-

powder

-

Material:

-

Nickle,chrome.molybdenum,niobium

-

Chemical Composition:

-

Ni.Cr.Mo.Nb

-

Product name:

-

SLS Metal Powder Inco Nickel Alloy 718 Inconel 718 Powder

-

Color::

-

Gray

-

Application::

-

3D printing Industry, 3D printing metal powder

-

Shape::

-

spherical

-

purity::

-

99.9%

-

Features::

-

fatigue and creep-rupture

-

Density::

-

0.296 lb/in3 annealed

-

Melting Range::

-

2410 - 2540°F

-

Hardness, Rockwell:

-

42-44

-

Temperature::

-

-423° to 1300°F

Product Description

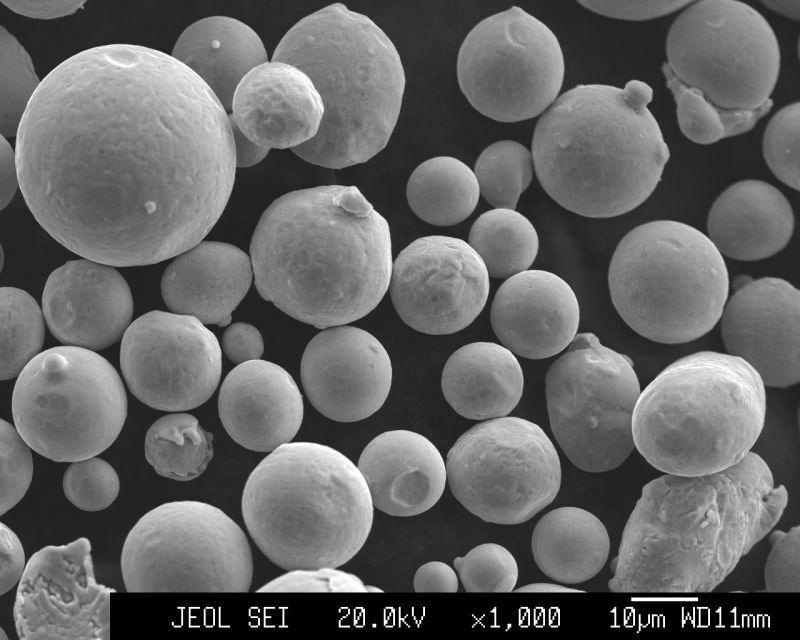

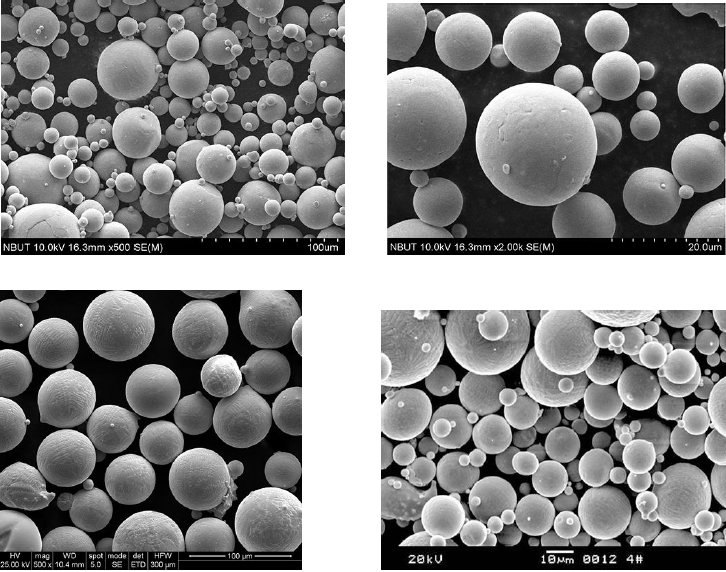

SLS Metal Powder Inco Nickel Alloy 718 Inconel 718 Powder

Through the different particle size distribution,Nickel 718 powder can be subdivided into injection molding powder, laser cladding powder, spraying powder, hot isostatic pressing powder and so on.

Application:

1.HVOF

2. Plasma coating

3.3D printing

4.powder welding

5.metal injection molding

6.hot isostatic

|

Chemical Composition(%) of Inconel 718 Powder

|

|

|

|

|

|

|

|

|||||||

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Co

|

Mo

|

|||||||

|

≤0.08

|

≤0.35

|

≤0.35

|

≤0.015

|

≤0.015

|

17-21

|

≤1.0

|

2.8-3.3

|

|||||||

|

Nb+Ta

|

Ti

|

Al

|

Fe

|

Cu

|

Ni

|

N

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

4.75-5.5

|

0.65-1.15

|

0.2-0.8

|

Bal

|

≤0.03

|

50-55

|

≤0.006

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

Inconel 718 Powder Properties

|

|

|

|

|

|

|||||

|

Size Range

|

0~25um

|

0~45um

|

15~45um

|

45~105um

|

75~180um

|

|||||

|

Morphology

|

Spherical

|

Spherical

|

Spherical

|

Spherical

|

Spherical

|

|||||

|

PSD

(Particle Size

Distribution)

|

D10: 6um

|

D10: 9um

|

D10: 14um

|

D10: 53um

|

D10: 78um

|

|||||

|

|

D50:16um

|

D50: 28um

|

D50: 35um

|

D50: 69um

|

D50: 120um

|

|||||

|

|

D90: 23um

|

D90: 39um

|

D90: 45um

|

D90: 95um

|

D90: 165um

|

|||||

|

Flow ability

|

N/A

|

≤30S

|

≤28S

|

≤16S

|

≤18S

|

|||||

|

Apparent Density

|

4.2g/cm3

|

4.5g/cm3

|

4.4g/cm3

|

4.5g/cm3

|

4.4g/cm3

|

|||||

|

Oxygen Content

(wt % )

|

O: 0.06~0.018wt% , ASTM standard : ≤0.02 wt%

|

|

|

|

|

|||||

|

3D printing Gas Atomized Inconel 718 Powder with the best price

|

|

|

|

|

|

|||||

|

(low oxygen , high sphericity and good flowability)

|

|

|

|

|

|

|||||

Advantage of HUARUI metal powder

●Even powder composition, less impurities

●Even powder composition, less impurities

●High sphericity

●Low oxygen content

●Good flowability

●High loose density, high tap density

●less h

ollow powder, less satellite powder

Applications

Part of Application

3D Printing

Plasma coating

Quality control system

The reason why HAURUI stand here form Year-2009

Benfits from the strict quality management system.

Huarui has the privilege of being recognized by a number of industry and customer awards for design, quality, and service over ten years.

Our services

Recommend Products

Hot Searches