most colored rubber mulch will be used in garden, floor or yard as filler, if used in rector to make fuel oil, then not only protect the rector, but also higher the capacity.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4*2.6*3.2m

-

Year:

-

2024

-

Power (kW):

-

44 kW

-

Weight (KG):

-

8000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

-

Advantage:

-

long service time

-

Key word:

-

portable tire shredder for sale

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

LIKE

-

Voltage:

-

220V/380V customized

-

Dimension(L*W*H):

-

4*2.6*3.2m

-

Year:

-

2024

-

Power (kW):

-

44 kW

-

Weight (KG):

-

8000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

-

Advantage:

-

long service time

-

Key word:

-

portable tire shredder for sale

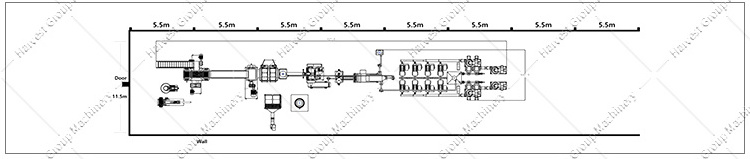

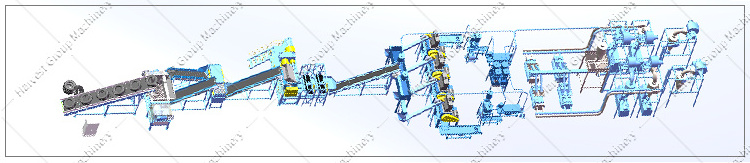

waste tire recycling rubber powder machine used tire processing equipment

The LK-M series miller is used to grind rubber powder. it is belong to final step in whole waste tire recycling production line.

the first step is TS series tire shredder machine, is used to shred the whole tire into TDF rubber chips in 50*50mm.

the second step is HVST-R series tire rasper machine, is used to make the rubber mulch in 10-30mm. it can be colored rubber mulch as filler of lawn or garden.

the Third step is LK-G series tire granulator, is used to make the crumb rubber or rubber granules without wire and nylon. it is third step in whole tire recycling production line.

the car tires, truck tires, trailer tires, OTR tires upto 4000mm can be shredded by our tire shredder;

whatever the frozen tires or not clean tires both can be processed by our machines.

Feature

The pre-grinding system can be equipped with bolt cutting tools to minimize operating costs and simplify line maintenance.

The two-stage rasper system effectively releases steel from the rubber for efficient separation and clean line production.

The fine granulation system is equipped with a special rotor specially designed to reduce the rubber size of the tire. It provides maximum throughput while minimizing the amount of fines generated. The machine is also optimized for low operating and wear costs.

Inhale textiles and dust at several locations in the recycling system.

The central reverse jet filtration system extracts dust from the entire system.

Our milling system can be installed at the rear of the tire recycling system. The size and configuration of the milling system is configured according to specific production requirements, ie size and throughput.

An advanced sound attenuating enclosure is available to reduce the noise level of the system to <85dBA.

Water spray and atomization systems are installed on critical components to keep process temperatures safe and prevent fires.

System automation ensures component operation links, maximizes system capacity, and best protects the system from interfering materials.

|

Step 1: Automatic double shafts tire shredder machine: final rubber size is 50-150mm TDF

|

|

|

|

|

||||

|

Model

|

Feeding size

|

Output size

|

Capacity

|

Motor

|

||||

|

TS-800

|

800mm

|

50*50mm

|

1-2 T/H

|

2*22KW

|

||||

|

TS-1200

|

1200mm

|

60*60mm

|

3-5 T/H

|

2*37KW

|

||||

|

TS-1600

|

1600mm

|

50-150mm

|

6-8 T/H

|

2*45KW

|

||||

|

TS-1800

|

1800mm

|

50-150mm

|

7-10 T/H

|

2*55KW

|

||||

|

Step 2: rubber rasper machine: removing the wire from rubber mulch and cut the rubber block to 10-30mm rubber mulch without wire.

|

|

|

|

|

||||

|

Model

|

Power

|

Capacity

|

Weight

|

Output size

|

||||

|

LK-R75

|

75KW

|

0.7-1T/H

|

3500KGS

|

10-30mm rubber mulch

|

||||

|

LK-R90

|

90KW

|

1-1.5T/H

|

4200KGS

|

10-30mm rubber mulch

|

||||

|

LK-R132

|

132KW

|

1.5-3T/H

|

6100KGS

|

10-30mm rubber mulch

|

||||

|

LK-R315

|

315KW

|

3-6T/H

|

12400KGS

|

10-30mm rubber mulch

|

||||

|

SPECIFICATIONS FOR TIRE GRANULATOR MACHINE

|

|

|

|

|||

|

Model

|

LK-G90

|

LK-G45

|

LK-G37

|

|||

|

Input size

|

30mm

|

30mm

|

30mm

|

|||

|

Output size

|

1-7mm

|

1-7mm

|

1-7mm

|

|||

|

Capacity

|

1-1.5tons/hour

|

0.5-1tons/hour

|

0.3-0.5tons/hour

|

|||

|

Dimension

|

2150*2250*2950mm

|

1765*1900*2435mm

|

1765*1600*2435mm

|

|||

|

Weight

|

5.6T

|

3.3T

|

3.0T

|

|||

|

Final step: miller can grind the rubber granules to fine rubber powder, most used in rubbered asphalt

|

LK-M3000

|

LK-M2000

|

LK-M1000

|

|||

|

Model

|

LK-M3000

|

LK-M2000

|

LK-M1000

|

|||

|

Output size

|

30-120mesh

|

30-120mesh

|

30-120mesh

|

|||

|

capacity

|

3000kgs/h

|

2000kgs/h

|

1000kgs/h

|

|||

|

motor power

|

1033kw

|

680kw

|

347kw

|

|||

the rubber powder in 30-120mesh

10-30mm colored rubber mulch.

1-7mm rubber granules.

mainly used in running track and playground after making rubber tiles.

LiKe Recycling Located in Zhengzhou City, Henan province, was established in 1997, one of the earliest leading professional manufacturers of environmental protective equipment, such as tire recycling machines, e-waste recycling machines, copper wire recycling machines. With advanced production experience, first-class management technology and the professional after-sale service team, our products not only occupy the domestic market, but also export overseas continuously, which has received unanimous praise from our clients. Our factory always aims to put customers' needs at first place, and has consistently tried to upgrade its products for more than 20 years. Our tire recycling production line have already obtained good market for their high quality and reliable technology.

We are based in Henan, China, start from 2013,sell to South America(20.00%),Africa(20.00%),Southeast Asia(20.00%),North America(10.00%),Western Europe(10.00%),Eastern Europe(10.00%),Mid East(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Waste Tire Recycling Machine/Rubber Crusher/Tire Shredder/Tire Crusher/E-waste Recycling/Metal Shredder/Cable Wire Recycling, Waste Tire Recycling Machine/Metal Shredder/PCB Recycling/Copper Wire Recycling

4. why should you buy from us not from other suppliers?

1.Our factory established in 1987, With nearly 30 years experience 2. All machines are 2 years warranty 3. Competitive price with high quality 4.We got SGS inspection certificate and CE certificate 5. Factory visited is welcomed

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Arabic,Korean