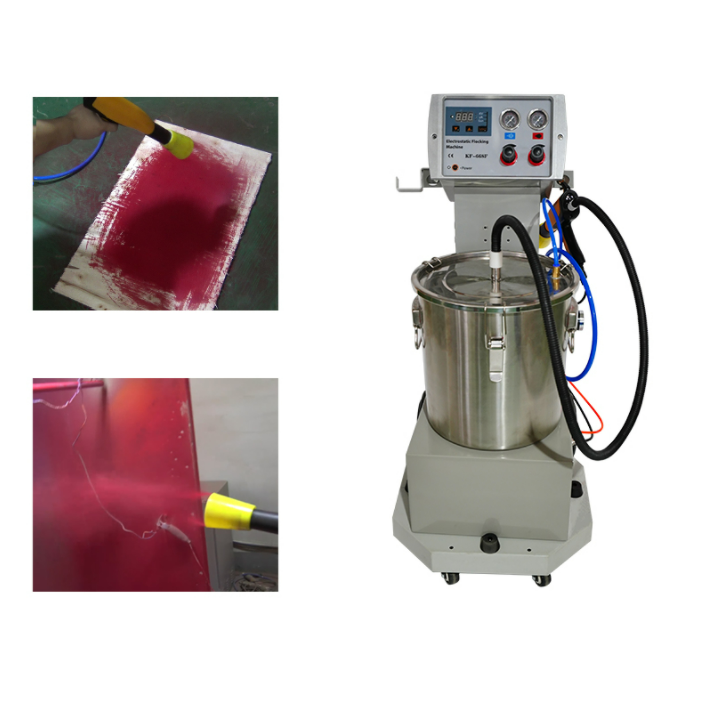

1>The controllor offers the flexibility to change voltage from 0-100kv which digitally shows on the display.

2>Regulation valves allows fully adjustable air for conveying, dosage and nozzle rinsing.

3>100kv high voltages spray gun generator ensures high transfer efficiency.

4>Ideally suited to continuous and smooth flocking for medium and large jobs.

5>Professional design makes it easy to penetrate corners of complex substrates

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/110V

-

Power:

-

50HZ~60HZ, 40W

-

Dimension(L*W*H):

-

to be confirmed

-

Weight (KG):

-

80

-

Model:

-

KF 668 Flocking machine

-

Power range:

-

220V/110V

-

Max voltage:

-

0-100KV adjustable

-

Output current:

-

0-150uA

-

Pulse Frequence:

-

15-20 clock/S

-

qoeking temperature range:

-

-10~45°C

Quick Details

-

Machine Type:

-

Electrostatic Flocking Velvet Machine, Painting Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kafan

-

Voltage:

-

220V/110V

-

Power:

-

50HZ~60HZ, 40W

-

Dimension(L*W*H):

-

to be confirmed

-

Weight (KG):

-

80

-

Model:

-

KF 668 Flocking machine

-

Power range:

-

220V/110V

-

Max voltage:

-

0-100KV adjustable

-

Output current:

-

0-150uA

-

Pulse Frequence:

-

15-20 clock/S

-

qoeking temperature range:

-

-10~45°C

Product Description

KF-668

Electrostatic Flocking Velvet Machine

Electrostatic flocking machine works to charge fiber particles which are then attracted to the ground-connected substrate that is to be flocked. The substrate surface should be applies adhesive before flocking.

With the electric field lines of force, the charged fibers become aligned and moves towards the adhesive coated substrate and becomes embedded. Fibers are adhered perpendicular to the surface giving a desired velvet finish. This technique optimizes the results to obtain longer fiber and good coverage on three dimensional objects.

With the electric field lines of force, the charged fibers become aligned and moves towards the adhesive coated substrate and becomes embedded. Fibers are adhered perpendicular to the surface giving a desired velvet finish. This technique optimizes the results to obtain longer fiber and good coverage on three dimensional objects.

|

Mode

|

KF-668 flocking Swab machine

|

|

Powder Range

|

220V/110V

|

|

Frequency

|

50hz/60HZ

|

|

Max vlotage

|

0-100KV

|

|

Fluff length

|

<=3mm

|

|

working temperature range

|

-10 ℃~45 ℃

|

|

Max powder injection

|

550g/min

|

|

Max air consumption

|

13Nm3/h

|

|

Pulse frequence

|

10-20 clock/s

|

Electrostatic Flocking Velvet Machine Advantages

Electrostatic Flocking Velvet Machine Applications

1>Textile/Garment/T-Shirt/Saree flock printing industries.

2>Automotive industry for coating window rubbers, glove boxes, coin boxes, door cards, dashboards.

3>Artistic products including the decoration of Jewellery boxes, Gift Boxes, Toys, 3D Objects, Wall Paper, Velvet Finish products,

4>Flock can be applied to an endless range of materials including Fabric, Paper, Plastic, Metal, Wood, Rubber and Leather products.

2>Automotive industry for coating window rubbers, glove boxes, coin boxes, door cards, dashboards.

3>Artistic products including the decoration of Jewellery boxes, Gift Boxes, Toys, 3D Objects, Wall Paper, Velvet Finish products,

4>Flock can be applied to an endless range of materials including Fabric, Paper, Plastic, Metal, Wood, Rubber and Leather products.

Certifications

Recommend Products

Packing & Delivery

Hot Searches