- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

runxiang

-

Year:

-

2023

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1.5 T

-

Motor Power (kw):

-

50 kw

-

After-sales Service Provided:

-

Video Technical Support

-

Keyword:

-

Hydryalic Press Machine

-

Application:

-

Sheet Metal Cold Press

-

Function:

-

Stamping Metal Product

-

Material:

-

Steel Material

-

Structure:

-

Vertical Presses

-

Capacity:

-

100T ~ 5000T

-

Key Words:

-

Hole Punching Machine

-

Package:

-

Wooden Case

Quick Details

-

Machine Type:

-

Four-column Two-beam Hydraulic Press

-

Ejector Force (kN):

-

Custom

-

Return Force (kN):

-

630 kN

-

Place of Origin:

-

China

-

Brand Name:

-

runxiang

-

Year:

-

2023

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1.5 T

-

Motor Power (kw):

-

50 kw

-

After-sales Service Provided:

-

Video Technical Support

-

Keyword:

-

Hydryalic Press Machine

-

Application:

-

Sheet Metal Cold Press

-

Function:

-

Stamping Metal Product

-

Material:

-

Steel Material

-

Structure:

-

Vertical Presses

-

Capacity:

-

100T ~ 5000T

-

Key Words:

-

Hole Punching Machine

-

Package:

-

Wooden Case

Product Description

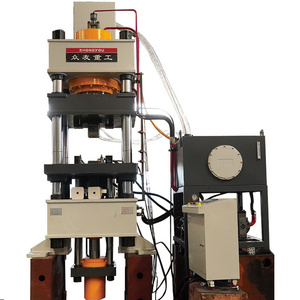

A hydraulic press is a machinery that uses hydraulic principles to generate a compressive force by applying pressure to a workpiece. It is used in various manufacturing processes that involve shaping, punching, or cutting metals, plastics, and other materials.

Feature

1. High Pressure Capacity: Hydraulic press machines generate a high-pressure force that can easily exceed 1000 pounds, making them ideal for heavy-duty applications like metal forming and forging.

2. Variable Speeds: With hydraulic press machines, you can easily adjust the pressure, speed and stroke of the press, giving more flexibility and precision to your operations.

3. Versatility: Hydraulic press machines come in a wide range of sizes and can be used for a variety of applications such as deep drawing, blanking, punching, gluing, and more.

4. Durability: Hydraulic press machines are designed to withstand high loads and harsh working environments, which makes them durable and long-lasting.

5. Safety: Hydraulic press machines tend to be safer to use than other types of presses because they have built-in safety

mechanisms such as overload protection, pressure relief valves and automatic shut-off switches.

1. High Pressure Capacity: Hydraulic press machines generate a high-pressure force that can easily exceed 1000 pounds, making them ideal for heavy-duty applications like metal forming and forging.

2. Variable Speeds: With hydraulic press machines, you can easily adjust the pressure, speed and stroke of the press, giving more flexibility and precision to your operations.

3. Versatility: Hydraulic press machines come in a wide range of sizes and can be used for a variety of applications such as deep drawing, blanking, punching, gluing, and more.

4. Durability: Hydraulic press machines are designed to withstand high loads and harsh working environments, which makes them durable and long-lasting.

5. Safety: Hydraulic press machines tend to be safer to use than other types of presses because they have built-in safety

mechanisms such as overload protection, pressure relief valves and automatic shut-off switches.

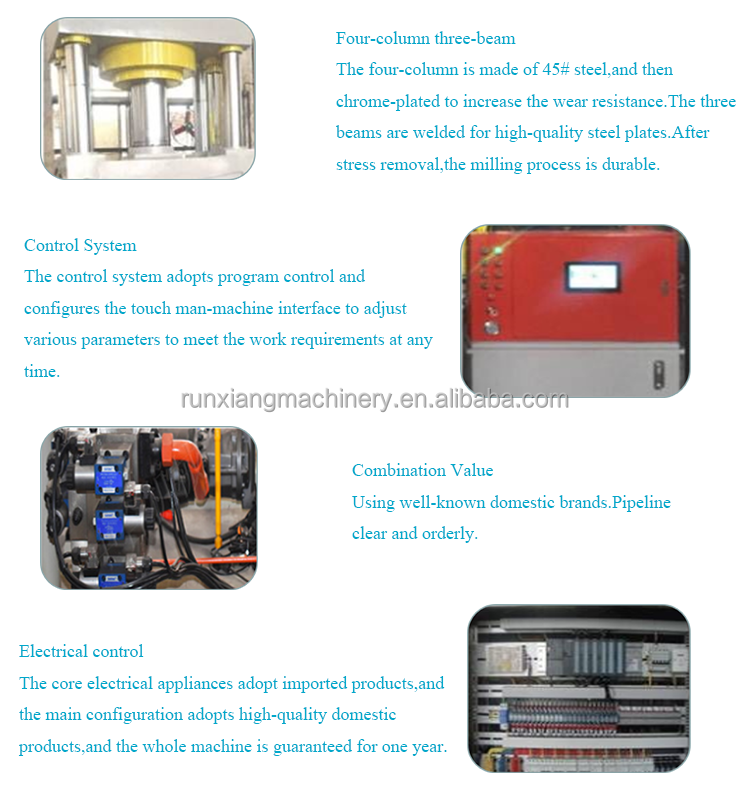

Detailed Images

Parts of Hydraulic Press Machine:

1. Cylinder: The hydraulic press cylinder converts energy generated by the pump into mechanical force that generates pressure.

2. Pump: The hydraulic press pump pressurizes the fluid which is then transmitted to the cylinder.

3. Valves: The hydraulic press valves control the flow and pressure of the hydraulic fluid within the system.

4. Pistons: The pistons convert pressure from the hydraulic fluid into physical force that is applied to the workpiece

5. Reservoir: The hydraulic press reservoir stores the hydraulic fluid.

6. Motor: The hydraulic press motor drives the pump to create pressure and force within the hydraulic system.

1. Cylinder: The hydraulic press cylinder converts energy generated by the pump into mechanical force that generates pressure.

2. Pump: The hydraulic press pump pressurizes the fluid which is then transmitted to the cylinder.

3. Valves: The hydraulic press valves control the flow and pressure of the hydraulic fluid within the system.

4. Pistons: The pistons convert pressure from the hydraulic fluid into physical force that is applied to the workpiece

5. Reservoir: The hydraulic press reservoir stores the hydraulic fluid.

6. Motor: The hydraulic press motor drives the pump to create pressure and force within the hydraulic system.

1. High Efficiency: Hydraulic press machines convert hydraulic energy into mechanical energy with high efficiency, which reduces production time and energy costs.

2. Variable Speed Control: Hydraulic press machines can be programmed to perform at different speeds and pressures, depending on the application. This reduces wear and tear on machinery, which translates to a longer lifespan.

3. Precision: With hydraulic press machines, you can achieve precise and accurate results due to their ability to adjust

pressure and speed.

4. Safety Features: Hydraulic press machines have built-in safety features such as emergency stops, pressure relief valves, and overload protection, which prevent accidents and downtime.

5. Customization: Hydraulic press machines can be tailored to meet specific requirements, including different sizes, weights, speeds, and pressures.

2. Variable Speed Control: Hydraulic press machines can be programmed to perform at different speeds and pressures, depending on the application. This reduces wear and tear on machinery, which translates to a longer lifespan.

3. Precision: With hydraulic press machines, you can achieve precise and accurate results due to their ability to adjust

pressure and speed.

4. Safety Features: Hydraulic press machines have built-in safety features such as emergency stops, pressure relief valves, and overload protection, which prevent accidents and downtime.

5. Customization: Hydraulic press machines can be tailored to meet specific requirements, including different sizes, weights, speeds, and pressures.

Size Information

|

Model

|

|

HP32- 63T

|

HP32-100T

|

HP32- 150T

|

HP32- 200T

|

HP32- 250T

|

HP32- 315T

|

|

|

Nominal pressure(KN)

|

|

630

|

1000

|

1500

|

2000

|

2500

|

3150

|

|

|

Liquid working force (MPa)

|

|

25

|

25

|

25

|

25

|

25

|

25

|

|

|

Opening height(mm)

|

|

500

|

500

|

550

|

600

|

600

|

1300

|

|

|

Stroke(mm)

|

|

300

|

300

|

300

|

350

|

350

|

500

|

|

|

Cylinder Diameter(mm)

|

|

200

|

260

|

280

|

340

|

380

|

400

|

|

|

Stroke speed of slider

|

Idle

|

90

|

90

|

90

|

100

|

100

|

20

|

|

|

|

Working

|

12

|

18

|

15

|

10

|

16

|

16

|

|

|

|

Return

|

20

|

30

|

20

|

40

|

40

|

40

|

|

|

Effective size of table

|

Around

|

500

|

500

|

500

|

600

|

600

|

800

|

|

|

|

Before and after

|

500

|

600

|

600

|

700

|

700

|

850

|

|

|

Motor

|

|

5.5

|

5.5

|

5.5

|

7.5

|

11

|

15

|

|

Application

1. Metalworking: Hydraulic press machines are widely used in the metalworking industry for forming, cutting, punching, and bending metals. They can also be used for forging and drawing steel parts.

2. Automotive Industry: Hydraulic press machines are used to manufacture parts for engines, transmissions, and other components in the automotive industry.

3. Aerospace Industry: Hydraulic press machines are an essential piece of equipment for manufacturing aircraft parts, including hydraulic systems, landing gears, and engine assemblies.

4. Plastics Industry: Hydraulic press machines are used to shape and mold various thermoplastics, thermosetting plastics, and composites for various products like toys, automotive parts and building materials.

5. Woodworking Industry: Hydraulic press machines are utilized to shape and join wood products, such as furniture, cabinets, and doors.

2. Automotive Industry: Hydraulic press machines are used to manufacture parts for engines, transmissions, and other components in the automotive industry.

3. Aerospace Industry: Hydraulic press machines are an essential piece of equipment for manufacturing aircraft parts, including hydraulic systems, landing gears, and engine assemblies.

4. Plastics Industry: Hydraulic press machines are used to shape and mold various thermoplastics, thermosetting plastics, and composites for various products like toys, automotive parts and building materials.

5. Woodworking Industry: Hydraulic press machines are utilized to shape and join wood products, such as furniture, cabinets, and doors.

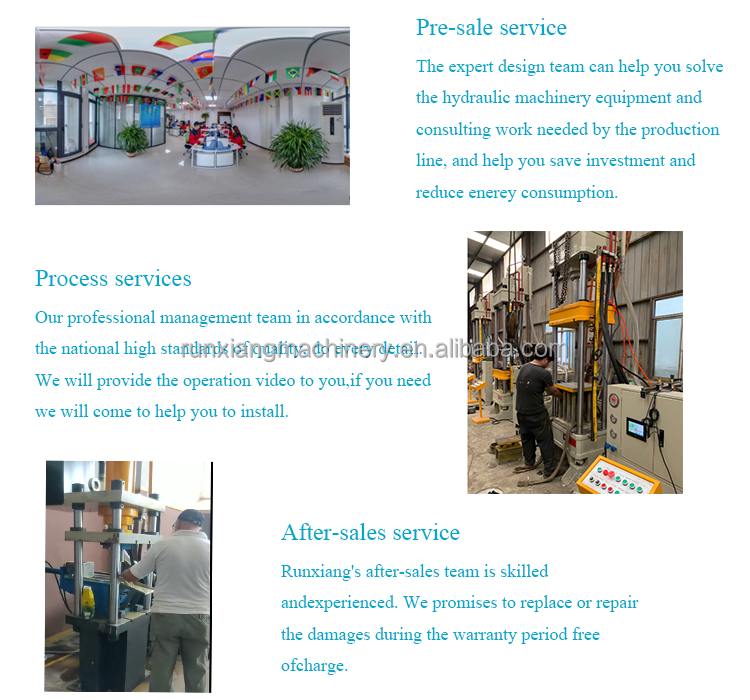

After sales-service

Maintenance of Hydraulic Machines

1. Regular Inspection: The hydraulic press machine should be inspected daily for any signs of damage or wear and tear before starting any operations.

2. Lubrication: All moving parts of the hydraulic press machine should be lubricated regularly to ensure smooth operation and to prevent corrosion.

3. Cleaning: The hydraulic press machine should be kept clean, with all debris and waste products cleared away from the work area.

4. Fluid Management: The hydraulic fluid should be monitored and changed as needed to ensure optimal performance and to prevent contamination.

5. Professional Service: Regular servicing of the hydraulic press machine by a trained technician can identify and rectify any issues before they lead to downtime or costly repairs.

In conclusion, hydraulic press machines are versatile, efficient, and durable equipment that are essential to many industries.

With the ability to generate high pressure forces, they provide a level of precision, customization and speed that is hard to

match with other machinery. However, proper maintenance is need

Best Selling

Recommending Styles

Company Introduction

FAQ

Hot Searches