- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AIX

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Grain

-

Name:

-

Grain Dryer

-

Function:

-

Drying Grain

-

Capacity:

-

2-10t/batch

-

Usage:

-

Grain Corn Paddy

-

Color:

-

Customer Required

-

Feature:

-

Low Temperature Cirtulating

-

Machine name:

-

Agricultural Equipment

-

Used for:

-

Bean Drying Machine

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

mobile grain dryer machine

-

Use:

-

grains drying

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AIX

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Grain

-

Name:

-

Grain Dryer

-

Function:

-

Drying Grain

-

Capacity:

-

2-10t/batch

-

Usage:

-

Grain Corn Paddy

-

Color:

-

Customer Required

-

Feature:

-

Low Temperature Cirtulating

-

Machine name:

-

Agricultural Equipment

-

Used for:

-

Bean Drying Machine

-

Certification:

-

CE ISO

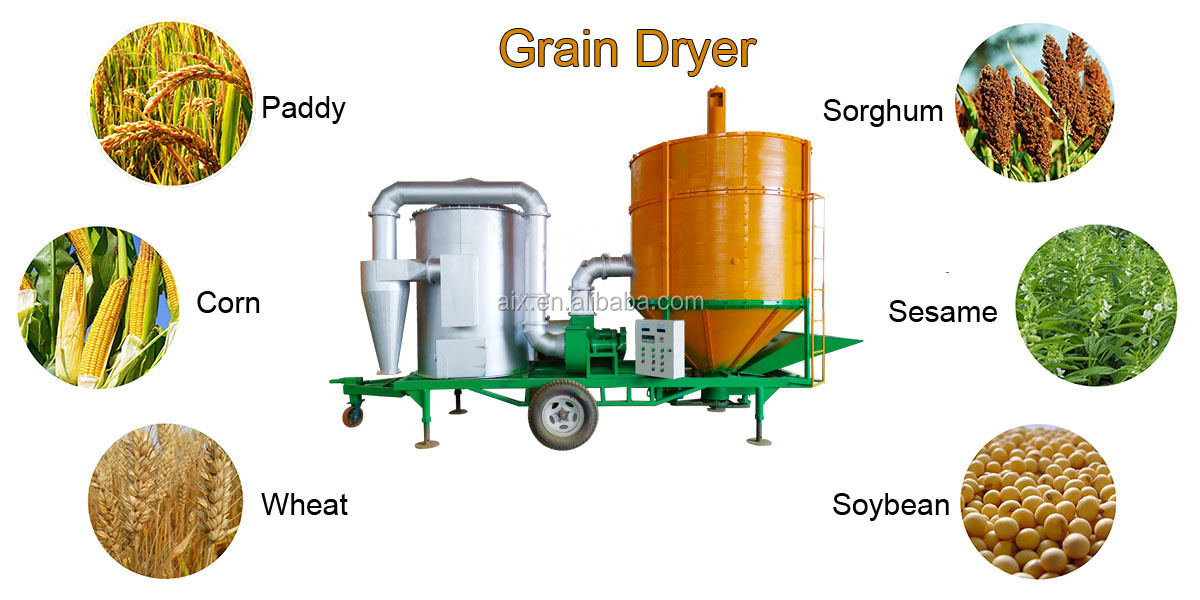

small rice paddy dryer machine for sale rice/paddy dryer hot air grain dryer

The grain dryer is an ideal drying equipment for drying grain and grain. It can be used for one machine. Dry rice, rapeseed, soybean, wheat, corn, peanut and other grains can be dried on the same equipment to meet different grain seasons. Drying, drying of feed grain, commercial grain and seed grain can be carried out to improve the utilization rate and reduce the idle time of equipment. The drying equipment is very suitable for use in food processing plants, lexical processing plants, farms, grain stations, grain farmers, cooperatives, grain depots, grain and oil processing plants and other user groups.

Working principle

Movable grain dryer (mobile grain drying equipment) uses hot air as drying medium and adopts cyclic drying technology. The grain is heated and precipitated uniformly, fully and has good quality after drying. The grain dryer uses coal, firewood, straw or rice husk as fuel, which is converted into clean hot air through combustion and heat transfer. The grain dryer is also equipped with an automatic on-line temperature and humidity measuring device, which greatly improves the degree of automation and ensures the quality of grain after drying.

Technical data

|

Model |

AIXD-10 |

AIXD-20 |

AIXD-30 |

AIXD-40 |

||

|

Silo Volume |

3.8m³ |

6.5m³ |

9.6m³ |

15.6m³ |

||

|

Dry type |

Low temperature hot air and grain Mixed flow cycle |

|||||

|

Hot air temperature |

Paddy:45-60℃;Corn:100-130℃;Wheat:90-110℃ |

|||||

|

Transport height |

2.7m |

2.9m |

2.9m |

2.95m |

|

|

|

Operation height |

3.46m |

3.85m |

4.92m |

6.65m |

|

|

|

Area |

13m2 |

15.5m2 |

16.3m2 |

25m2 |

|

|

|

Oven |

Clean oven Ignition by manual Fuel can be coal,desiel oil,natural gas,etc |

|||||

|

Fuel consumption |

Coal |

(Standard conditions)18kg/t |

||||

|

Gas |

(Standard conditions)7m³/t |

|||||

|

Diesel oil |

(Standard conditions)7.5L/t |

|||||

|

Total power |

8.5 |

12.9 |

19.4 |

36 |

|

|

|

Daily Production: |

20 t/day |

35 t/day |

50 t/day |

80-100 t/day |

|

|

|

Room temperature |

-10-40℃ |

|||||

|

Feeding time |

8-10 min |

12-16 min |

18-22 min |

22-28 min |

|

|

|

Discharging time |

8-10 min |

10-15 min |

15-20 min |

20-25 min |

|

|

|

Precipitation rate (%/h) |

Paddy:1.7-2.5;Corn:3.8-6;Wheat:2.8-4.5 |

|||||

|

Safety Devices |

Thermal relay,Error alarm, Times Switch, Overheat alam |

|||||

|

The performance of above parameter and Precipitation rate is for reference value,the actual value will be different due to atmospheric temperature,relative humidity,dry species,hot air temperature and moisture content and drying rate.Daily production is calculated by the condition from25% to 14% moisture. |

||||||

If your are interested in our machine and want more details,pls contact me to inquiry.

Equipment component

The hot blast stove equipped with the grain drying equipment is an energy-saving and environment-friendly hot blast stove. The hot blast stove can be used for various dryers. The hot blast stove supplies heat to indirectly dry the grain. During the drying process, the grain continuously circulates and the grain rubs against each other. The awns, velvet hair, etc. on the surface of the grain are removed, and the dust is removed from the machine to improve the cleanliness of the dried grain. The production cost of this grain dryer is low. The supporting drying oven can use coal, electricity, natural gas and waste biomass, such as rice husk, corn broken shaft, wood foot and so on as dry heat source, fuel selection, no fuel, dry Low cost, energy saving and environmental protection.

The grain discharging device of the grain dryer adopts the sliding valve structure, and the material is not damaged during operation, and the speed of discharging the grain can be controlled by frequency conversion according to the output and water removal requirements, which can meet the needs, and can be based on the requirements of seed grain or commodity grain. Adjust the drying speed to meet the quality requirements.

The grain dryer is also equipped with safety protection devices, temperature control devices, electrical overload protection devices, leakage protection devices, and fire protection equipment.

Tower type grain dryer

Technical data

|

model |

AIXGH-15 |

|

structure |

Batch type circulating |

|

capacity |

15ton per batch |

|

Total weight |

3000kg |

|

dimension |

4320*2492*10090mm |

|

Rated air flow |

6677-13353m^3/h |

|

Fuel consumption(rice hull) |

30-40kg/h |

|

fuel |

Rice hull/firewood/straw/anthracite |

|

Total power |

15kw |

|

Loading time |

50-70min |

|

Unloading time |

50-70min |

|

Drying rate |

0.5-1.2%/h |

|

Safety device |

Grain temperature sensor,fault alarm,full load buzzer,over otemperature alarm,thermal-over relay,hot air temperature sensor,overload protection device,leakage protection device |

Also have 6ton,8ton,10ton,25ton,32ton,60ton per batch model for choice.More details, pls do feel free to contact us.

Our market

Zhengzhou Aikesi Machinery Equipment Co., Ltd. is a mechanical company integrating R&D and manufacturing. It specializes in grain machinery and has more than 20 years of R&D and manufacturing experience. Our products include rice milling plant, grain dryer, flour mill plant, large feed production plant, etc. We provide planning and design services.

Quality first, customer first, is our constant pursuit and unremitting efforts.